Biodigester and Feedstock Type: Characteristic, Selection, and Global Biogas Production

Journal of Engineering Research and Sciences, Volume 1, Issue 3, Page # 170-187, 2022; DOI: 10.55708/js0103018

Keywords: Biogas, Anaerobic digestion, Feedstock type, Bioreactor, Chicken manure

(This article belongs to the Section Chemical Engineering (CHE))

Export Citations

Cite

Abubakar, A. M. (2022). Biodigester and Feedstock Type: Characteristic, Selection, and Global Biogas Production. Journal of Engineering Research and Sciences, 1(3), 170–187. https://doi.org/10.55708/js0103018

Abdulhalim Musa Abubakar. "Biodigester and Feedstock Type: Characteristic, Selection, and Global Biogas Production." Journal of Engineering Research and Sciences 1, no. 3 (March 2022): 170–187. https://doi.org/10.55708/js0103018

A.M. Abubakar, "Biodigester and Feedstock Type: Characteristic, Selection, and Global Biogas Production," Journal of Engineering Research and Sciences, vol. 1, no. 3, pp. 170–187, Mar. 2022, doi: 10.55708/js0103018.

This work aims at providing factual details necessary for the utilization of diverse feedstock for anaerobic digestion (AD) to produce biogas using either conventional or non-conventional types of digesters. This is necessary as different substrates had peculiar merits or potentials of biogas production due to their unique characteristics. Selection of right feedstock is usually based on sustainability, quantity, output requirement, availability and metallic nutrient content apart from digester type which is affected by the weather condition of the location among other factors. Global biogas production is increasing annually, especially in areas of biogas utilization for electricity generation, heating and fuel for transportation.

1. Introduction

Biomass are organic matter of plant and animal products that can be broken down physically or chemically [1, 2]. The simple act of breaking down these materials into smaller pieces could be termed physical decomposition while the use of microorganism is a chemical biodegradation process. The biodegradation process is carried out with or without oxygen. Aerobic fermentation is referred to as oxygen-free decomposition while anaerobic is vice-versa. The composition of the biogas produced from the respective processes are almost similar [3]. Biogas can be synthesized using different biomass sources providing an oxygen-free environment in the presence of anaerobic microorganisms [4–6]. It can be called a ‘cell gas’, as it comes from “biogenic materials” [3, 7-8]. The process of converting organic waste to biogas is termed AD. It was first introduced in 1870 by Jean-Louis Mouras [9]. AD is an alluring, slow, versatile biotechnological commercial route to transform organic waste or biodegradable material to useful resources by consortium of microorganisms living symbiotically [6-7, 9–13]. This biological process are carried out purposely to produce biogas and digestate [7, 14]. Biogas which is known for its composition of methane, carbon dioxide, oxygen, nitrogen, water, ammonia, hydrogen, siloxanes and hydrogen sulphide vary in this components composition if the substrate processed are not the same. In this case, the component that make up the biogas, methane is often targeted, because it is well pronounced in the characteristics of the gas. While the second co-byproduct is used as fertilizer. It can be called biological fertilizer, an alternative of the conventional or chemical fertilizer. Merits and drawback lies in the use of the AD process. Major advantage is the contribution to conservation of non-renewable energy sources and biogas production, while long retention time and low heating value of the produced gas, constitutes a disadvantage [12, 15] as shown in Table 1.

Table 1: Advantages and Disadvantages of AD Process [8]

Advantages of AD Process | Disadvantages of AD Process |

|

|

It is well known that feedstock to anaerobic bioreactors are basically biodegradable organic wastes. Millions of tonnes of waste is generated annually across various countries of the world, in both developed and developing countries [3]. India alone produces cumulatively ‘44 million tons + 500 Mt” annually of waste [10]. These wastes can be subjected to various waste treatment methods to recycle or convert them to useful materials [16]. In Table 2, biogas yields of various feedstock are compared; where it is observed that different feedstock produces different throughput of biogas.

Table 2: Comparison of biogas yields and electricity produced from different potential substrates [10]

Type | Biogas production (m3/ton fresh matter) | Produced kilowatt-hours (kWh) per ton fresh matter |

Cattle dung Chicken litter/dung Fat Food waste (FW) Fruit waste Horse manure Maize silage Municipal solid waste (MSW) Pig Slurry Sewage sludge | 55-68 126.0 826-1200 110 74 56 200-220 101.5 11-25 47.0 | 122.5 257.3 1687.4 224.6 151.6 114.3 409.6 207.2 23.5 96.0 |

During AD, feeding the biodigester continuously with water and organic waste is necessary to keep it running. Biogas automatically stops coming out of the outlet of the biodigester when the feedstock runs out [17]. Not all feedstock will require the addition of water. Where water is required to be added, this has to be done making sure the contents of the digester is not too diluted. Not adding the required amount, affects the working principle of the digester [17].

2. Conventional Biodigesters

There are three conventional reactor models used for biogas production, namely, fixed dome reactor model, floating drum digester model and the tube digester model [18]. Fixed-dome biogas digester, also called the hydraulic reactor model is a semi batch reactor originating from China in 1936, and it is the most commonly built [6, 19–21]. It has an underground pit or manhole lined with reinforced concrete slab or bricks in order to protect it from physical damage from excessive pressure and to save space [3, 21]. The filling hole or fermentation chamber is where organic waste resides for AD take place. It also have an inlet to add feed to the digester, a non-movable or fixed dome gas holder or gas reservoir, constructed with granite, sharp sand, cement and iron rods at the upper part of the reactor for gas storage, a displacement or compensation tank where displaced slurry enter during gas production and an outlet pipe with a valve/faucet attached to the dome top where the emerging biogas flows to be collected in a storage tank also connected to the outlet pipe [3, 6, 21, 22]. Gas is produced under pressure. The volume of gas generated is proportional to the gas pressure and implies that, as the pressure increases, gas volume increases. The advantage of the Chinese digester is that, it is simple, occupies less area, having relatively low cost of construction, having a long lifespan of above 20 years and consist of no moving parts [3, 23]. The disadvantage of this type of digester model is that gas pressure is not stable (caused by absence of gas valve in the outlet) and is prone to cracks in the gas reservoir [22]. The amount of waste and water to use as feed and the local climate are some of the factors important to consider during its design [6]. Centre for Agriculture Mechanization and Rural Technology (CAMARTEC) model designed by GIZ for use in Tanzania, French model installed in Pakistan and Deenbandhu 2000 (a modification of the Janta model) developed in India are three variations of the fixed dome plant [24, 25].

The floating drum biogas plant was first designed in India and built with sand, cement materials and bricks [23]. It comprises of a cylindrical or dome-shaped underground digester and a moving gas holder floating over the fermentation slurry. This floating iron drum is placed upside down to hold the gas produced. The drum moves up and down based on the volume of gas stored (up, when the gas increases and down, when it decreases) and a guiding frame is kept to prevent it from tilting [3]. The disadvantage of this design is that, it has a shorter life span compared to the Chinese model, it is prone to corrosion due to the high cost of steel drum and requires regular painting during its maintenance. The strength of the model is its simplicity in building and easy operation [22]. The balloon or tubular biodigester model is set up using a large and strong plastic bag placed on a dug trench for its safety and linked to a piece of drainpipe at either end [23]. These pipes are the outlet and exit pipes (which is at one top end) for discharge of slurry and removal of gas respectively. The top of the bag starts to inflate as biogas is produced and is piped away [17]. Gas pressure can be increased when some loads are placed on top of the bag. Balloon bioreactor merits are namely, easy to clean, simple construction and operation, easy to relocate, lightweight, easy to install and cheap manufacturing cost [26]. The biggest disadvantage associated with the model is its ability to get damaged easily and a short lifetime of 4 years [22]. It is also called the polyethylene tubular digester, prominently in use in South Africa, Vietnam, Cambodia, Colombia, Ethiopia, Bangladesh, Tanzania and countries of Latin America [21, 23, 25]. Unlike laboratory scale bioreactors where lots of research has been carried out on feedstock characteristics inside the digester (e.g. measure of cell and substrate concentration) and kinetic studies, the conventional reactors have not been so given attention. The distinguishing factors of the three digester types is shown in Table 3.

Table 3: Comparative table of the digesters [19, 21]

| Fixed Dome Plant | Floating Drum Plants | Balloon Plants |

Lifespan | 20 years or more | 15 years maximum | 2-5 years |

Size | 5-200 m3 | 5-15 m3 | 4-100 m3 |

Investment costs | Low | High | Low |

Cost of maintenance | Low | High | Low |

Gas pressure | Between 60 and 130 mbar | Up to 20 mbar | Low gas pressure |

Skilled required | High | High | Low |

Methane emission | High | Medium | Low |

Presently, there is the fourth kind of digester termed fiberglass digester consisting of a digesting part and storage part of which there is no any barrier or insulation between them. Advantages associated with its use is that it is movable, environmentally friendly, has a lightweight, has low investment cost, leaks are easily repaired and the ease of implementation and handling [22]. Also, membrane are suitable when managing inhibition triggered by ammonia accumulation because they have the capability of shielding microbes from inhibitors [27]. Membrane bioreactors or anaerobic membrane bioreactor (AnMBR) is a fascinating innovative technology for biogas production. Key setbacks related to an AnMBR system are its maintenance, installation, operating cost and membrane fouling [28]. AnMBR systems, just like conventional bioreactors operates at neutral pH.

2.1. Categories of Biodigesters

Based on method of operation, time and volume of feedstock available, biodigesters are classified into batch, semi-batch and continuous reactor. Batch reactors are in most cases fed with slurry to allow for digestion within a desired retention time and then discharged [5]. The continuous stirred tank reactor (CSTR) is one in which feedstock are continuously fed and products are continuously taken out. It is composed of an internal mixing system, based on wet process, operated in mesophilic conditions [29]. FW are commonly fed in CSTR after mixing adequately with water to prevent pumping and mixing difficulty as FW have high solid content greater than 15% [30]. Batch reactors are characterized with handling diversified substrate and higher volume compared to continuous digester. The weakness of batch system is that the initial cost and cost of synthesizing the same amount of biogas is almost twice that of continuous digester [19].

Apart from those three, although base on them, other type of digesters are anaerobic contact reactor (ACR), anaerobic pond, internal circulation reactor (ICR), anaerobic sequencing batch reactor (ASBR), up-flow anaerobic solid-state reactor (UASS), anaerobic plug-flow reactor (APFR), anaerobic baffled reactor (ABR), up-flow anaerobic sludge bed reactor (UASB), anaerobic fluidized bed reactors (AFBR), up-flow anaerobic sludge fixed-film (UASFF) reactors, membrane anaerobic system (MAS), modified anaerobic baffled reactor (MABR), ultrasonic membrane anaerobic system (UMAS), expanded granular sludge beds (EGSB) and upflow anaerobic filtration (UAF) [31–34]. The UASB is currently in use in Morocco to treat recycled paper mill wastewater because it is a suitable environment for the survival of microorganism as it permits a dense sludge system [28, 33]. EGSB has been tested by [33] to digest palm oil mill effluent (POME) in Nigeria and was found to yield the highest methane gas at low retention time over other types. The plug flow system allows the treatment of high amount of waste per unit digester volume, requires little or no water and reduces the need for pretreatment [30]. All the listed digester type have the advantage of large-scale application [31]. Specifically, two types of digesters for FW is

Green Cone FW Digester created by a British company called Great Green Systems is however, producing small amount of biogas, but the Ecofys Plastic Bag Digester, a technology of Netherland is made up of recyclable waste. Ecofys digester is considered portable, cheap, very easy to install and could last for 8 years. In terms of size, biogas plants are divided into small size plants (household scale) capable of delivering 0.5m3/day of biogas and large sizes (industrial scale) that can generate 2500 m3/day [26]. According to a United Nations Development Programme (UNDP) report, it takes 5-8 pigs, 4 adults human and 1-2 cows to supply sufficient substrate daily for a single-household bioreactor [35]. Countries like Lesotho, Uganda, Zambia, Zimbabwe, Burundi, Botswana, Nigeria, Sudan and Swaziland are known for small-to-medium scale digesters while Rwanda and South Africa had several large-scale digesters [24, 35, 36]. Between 2007-2012, Non-Governmental Organisations (NGOs) have help develop 17000 digesters cumulatively, in Rwanda, Tanzania and Ethiopia [37]. The same author stated that the population of Africa is projected to reach 2 billion by 2050, but currently the number of household size plants is just 18.5 million compared to China’s 200 million, showing a huge deficit and explains how far the continent is left behind as regards investing in the technology. Small sized and large digesters in Bangladesh in 2014 cumulatively generates 15 billion m3 of biogas, and plans to build additional 100,000 small scale biogas digesters in 2020 [21]. Several factors are considered when designing biogas plants, namely, plant safety, easy maintenance, weather condition, biogas output requirement, availability of feedstock, sustainability, easy operation among others. The priority of building a biogas plant is basically to minimize cost as it is a rural based technology where local materials are channeled to its construction [38].

3. Feedstock Classification for AD

Agricultural, municipal, and industrial wastes are the three primary kinds of organic waste [4, 32]. Livestock waste, harvest waste, grass and algae, energy crops, garden waste, and vegetable by-products are examples of agricultural wastes. Slaughterhouses, ranges, insect farms, and poultry houses all provide livestock wastes. Fish waste, insects and worms, poultry litter, keratin-rich waste, and manures are among them [39]. Insect farming technology produces biogas that is comparable to animal waste by cultivating silkworm and caterpillar excreta [40]. Poultry litter is a type of lignocellulosic bedding made up of spilt feed, excrement, and feathers [41]. Wool, horns, chicken feathers, hooves, hair, claws, and nails produced by the fish, meat, and wool industries are examples of keratin-rich waste [27].

Animal waste is referred to as manure, which is made up of a combination of water, straw, excrement (feces and pee), and sand [29]. Cattle, goats, chickens, pigs, deer, horses, and other animals are the source of manures [42]. A kg of cow dung can generate 0.03-0.05m3 of biogas whereas 50,000 cattle could deliver around 20000 m3/day of biogas [25, 40, 41]. In 2006, Food and Agricultural Organisation (FAO)’s findings shows that there are up to 277 million heads of cattle in Africa [43]. Nigeria’s biogas potential stood at 6.8 million m3/day from animal manure while in Zambia, animal dung potential for the gas is 1.473 109m3 [41, 43–45]. From the 21 million cattle population in 2001, estimates of daily manure production in Nigeria ranges from 210-1260 million kg ([44] gave a specific amount = 227,500 tons daily) while its annual capacity is 76.7-450 million tonnes [46]. The aggregate is 542.5 million tons/yr of livestock waste with potential of 25.53 billion m3 of biogas, 169541.66 MW of energy and 88.19 million tonnes of biofertilizer [39, 41, 47]. Third largest cattle breeders in Africa is Tanzania followed by Ethiopia and Sudan; boosting of 40 million animals out of which 18.8 million are cattle [36]. Distribution of manures across states and regions of seven countries (namely, Germany, Austria, Australia, Norway, Canada, Ireland and the United Kingdom) and their potential for biogas production had been presented previously by [48]. Total weight of waste generated from a certain location or town per year at every animal slaughter house can be estimated based on Equation 1 [20],

$$

M

=

\left[

E \times A_m

+

N \times (A_b + A_r)

\right]

\times 365

\tag{1}

$$

where, M = total amount of waste produced in that province (kg year-1), E = total number of live animals, N = total number of animals slaughtered, Am = amount of manure produced (kg day-1) and Ab & Ar = amounts of blood and rumen (kg day-1) produced at slaughter houses.

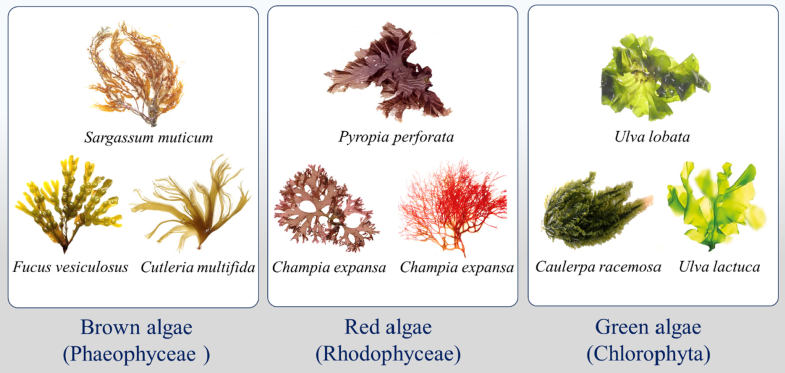

Silage grass, mushroom stick, and algae are all good agricultural AD substrates [42]. As illustrated in Figure 2, there are three varieties of microalgae for commercial biogas generation.

Red algae (Rhodophyceae) are the most common of these algae kinds [49]. Energy crops are grown specifically for the production of biofuels and biogas. Vinasse is a liquid leftover from sugarcane derivatives, sugar beet, and cassava, with a significant biogas synthesis potential [10, 13]. Leaves, garden clippings, plants, and cut grass are all examples of garden waste (GW) [50]. In many areas, harvest or agricultural wastes such as olive pomace, POME, stalk, straw, plant trimmings, and bark are a key source of AD feedstock [51–53]. Anaerobic bacteria have a hard time degrading crop straw to produce biogas [54]. Corn stover is made up of husks, stalks, leaves, and cobs that comes from corn grain production [55]. Wheat is one of the most widely grown crops on the planet, while silage corn is the most important crop for biodigester plants [46, 56]. The potential of crop residues for biogas generation in Zambia is 1.819 m3 according to [56].

Though there is no such thing as municipal liquid waste (MLW) in the literature, it is legitimate to separate municipal garbage into solid and liquid waste. FW, municipal waste water, landfill garbage, papers, green waste, urban sanitation, and aquatic biomass are only a few examples. These wastes come from a variety of places; possibly domestic, educational, medical, to mention a few [57]. FW is described as an uneaten, abandoned, or lost substrate of foods such as rice, noodles, nuts, pasta, eggs, fish, vegetables, fruits, meat, potato, and sweets during the stages of manufacturing, processing, distribution, and consumption [29, 40, 49–51]. Restaurants, canteens, markets, hotels, hostels, and household products all produce large volumes of FW [30]. Some of these wastes come from the listed buildings’ and locales’ kitchens [12]. In the kitchen, filthy water and various food remnants are produced. Vegetable residue, fruit peels, cooked food leftovers, and spices are just a few examples. Spices aren’t good for the AD process. Red chili, black paper, cinnamon, coriander, garlic, turmeric, cardamom, and clove are some of the spices used [15]. Daily biogas output from FW in Benin metropolis of Nigeria of up to 28836.91 m3 was generated from approximately 305.075 tonnes/day production rate based on [58].

Low biogas recovery is typical of municipal waste water [59]. Sewage sludge and gutter water are two examples [3]. Almost every sort of waste is accepted at the landfill, which is divided into organic and inorganic sub-types. MSW disposed off in a landfill by composting or open dumping is an example [4]. Leachate is generated in dump sites and produces a significant amount of biogas during AD [28]. School and printing presses both have paper. Cardboard, filter paper, waste paper, newspaper, and tissue paper are among them [60]. Estimates of Nigeria’s potential of MSW was put at 17 million tonnes [61]. Aquatic biomass could include lignocellosic biomass from aquatic weeds like water hyacinth (Eichhornia crassipes) and water primrose (Ludwigia hyssopifolia) [6, 54, 55].

Some of the industries that generate semi-solid and liquid organic waste for anaerobic digesters include the agricultural and food processing industries, fodder and brewery industries, wastewater treatment plants (WWTP), textile industries, fruit processing, sugar industry, and pharmaceutical industries [1, 2, 62]. Biomedical waste produces blood, which is also an important biogas source [63]. Sludge is a solid waste byproduct produced by WWTP [64]. Due to water scarcity, the number of WWTP has expanded in recent years, producing either settled primary sludge or waste activated sludge (WAS) from biological treatment [49, 57]. Four WWTP, namely, Abesan, Alausa, Iponri and Oke-Afa are too few for Lagos state (the most densely populated land area in Nigeria), being the largest emerging cities in the world with a small area of 3577 sq. km – that generates 1.4 billion litres of wastewater per day from a population of around 20 million [65]. In addition, this waste presents an enormous potential for biogas and biofertilizer production for the country.

Fruit processing plants generate two forms of trash [27]: (a) solid waste, which includes stones, skin, peels, and seeds, and (b) liquid waste, which includes wash-waters and juice. Banana, watermelon, citrus, mango, pineapple, and other fruits are examples. Waste that can be digested into liquid effluent trash (e.g. wastewater, manure slurry, sewage sludge and agro-food effluents) and organic solid waste can be distinguished (e.g. agricultural, industrial and municipal waste) [19]. Substrates aren’t picked at random. Always choose a substrate based on its long-term viability, energy efficiency, environmental impact, and economic value [11, 62].

3.1. Feedstock Characteristics

The composition of the feedstock should be the first deliberation while opting for organic matter that would give high yield of biogas. Handful of organic waste are difficult to break down in a digester, because they are indigestible (e.g. paper and impregnated wood), hard to digest, slow to digest, or contain inhibitors [1, 27]. Quantity and composition of feedstock can affect AD in the following way [66]: (a) dry matter content and viscosity of substrate causing stirring difficulty, (b) impurities affecting size and causing sedimentation, (c) digester’s size and shape defined by the slurry volume, (d) feedstock physical and chemical compositions [67] and (e) content of volatile solids (VS) and ammonia concentration. It is critical to dissect various feedstock and their composition; one which will significantly matter with regards to biogas output.

Animal dung contains parasites, viruses and bacteria (that keeps reproducing during AD) [17]. The most commonly used is cattle dung mixed with hot water (ratio = 1:1) [10]. Animal manure are low in C/N ratio as well as nitrogen content but rich in carbohydrate content [3, 9, 12]. Poultry residue are rich in nitrogen, and is therefore not recommended for efficient AD [3, 68]. Brown macroalgae are seaweed characterize with high polysaccharide content and negligible lignin content [49]. Other plant-based materials like vegetables, root crops, grains and fruits are rich in different polysaccharides [16]. The best pretreatment method for water hyacinth is 5%v/v H2SO4 with residence time (RT) of 1 hour [69]. Vinasse has low macro and micronutrients, deficient in carbon-to-nitrogen ratio and unpleasant smell [13]. Hence needs to be codigested with filter cake, straw and bagasse to solve the problem of its nutrient deficit. AD of agricultural waste is portrayed generally as having poor buffering capacity, low quality end products and potential variability [5].

Effluents wastewaters are sourced for AD basically from industries such as wastewater treatment plants. Waste activated sludge (WAS) from wastewater treatment plants (WWTPs) are rich in nitrogen, phosphorus, potassium, organic carbon, microbial biomass and exopolymeric substances; mainly proteins and carbohydrates [51, 70]. Apart from WWTP, wastewaters are sourced from industries discharging them. Municipal solid waste is typified by low chemical oxygen demand (COD) concentration, presence of toxic materials and high concentration of heavy metals [9, 52]. Domestic sewage are rich in nitrogen organisms [3]. Kitchen waste contains high nutritive and calorific value [71]. FW are non-homogenous in nature, has high water, VS and salinity content, low C/N ratio and is highly biodegradable [29, 49, 50]. They are either fat-rich, protein-rich or carbohydrate-rich materials. Fat-rich and protein-rich feedstock produces more methane than carbohydrate-rich feedstock [51].

3.2. Lignocellulosic Feedstock

It has been established that physical and chemical properties of the raw material are factors affecting the amount of biogas produced [70]. In [57], it was stated that characterization, elimination of contaminants, pretreatment, AD in optimum condition and utilization of energy crops enhanced the efficiency of an anaerobic digester. Cellulose, hemicellulose and lignin are lignocellulosic substrates [54, 59]. They are the main elements of the cell walls, require long retention time, have a high C/N ratio, high carbohydrate content and are recalcitrant towards AD process as they are highly nondegradable [4, 16, 60, 62, 69, 72]. High temperature and low retention time pretreatment of lignocellulose could effectively improve the porosity and delignification efficiency [5]. Cellulose and lignin are natural complex polymer found in wood [29]. Cellulose is a carbohydrate while lignin is non-carbohydrate. Examples of lignocellulosic matter are crop residue, corn stover, rice straw, corn stalk, wheat straw, water hyacinth, barley [16] etc.

Urea and acid pretreatment are the predominantly used pretreatment technologies for crop straw [54]. According to [55], corn stover typically comprises of 37.5 % cellulose, 22.4 % hemicellulose and 17.6 % lignin. Corn silage contain high C:N ratio and low ammonia [70]. Hard lignocellulosic structure and high C/N ratio of wheat straw of up to about 100 hinders production of biogas from wheat straw [12, 67]. Codigestion of rice straw is more desired because of its low nitrogen content, lignin percentage and high C/N ratio [5]. Just like tree plants, water hyacinth consisting of stem, leaf and root [69]

3.3. Chicken Manure as AD Feedstock

Chicken manure (CM) is an alkaline, semi-solid organic material that is made up of diverse composition of other organic materials, as well as being one of the most widely used feedstock for anaerobic production of biogas and biofertilizer [64, 73]. In [73], it was reported that daily chicken excretion ranges from 80-125g (wet)/chicken. Dry matter content or total solid (TS) content of CM is 20-25% of the excreta which is rich in nitrogen, with high amount of biodegradable fraction and VS content of 55-65% [65, 66, 73]. Percentage water content of more than 70% in CM is considered unattractive for utilization [74]. It also contain pathogens (methanogenic bacteria), high phosphorus, low C-N ratio, and high salinity level [71, 75]. [76] reported a CM with TS = 47.3%, pH = 8.1, VS = 68% and C-N ratio of 18. To prevent CM from decomposing, prior to AD, they are often kept at a very low temperature of -20°C [77]. Others have reported a higher temperature of 4 . Dry fermentation has the merits of high biogas production rates, low water consumption and low cost [78].

The agricultural sector where CM is derived, is the main source of total ammonia emission into the atmosphere [79, 80]. It has been stated clearly, that the high nitrogen content of CM makes it a suitable material for AD. However, nitrogen, together with sulphur inhibits the digestion process [81]. The level of nitrogen in CM is attributed to the conversion of uric acid and undigested proteins into total ammonia nitrogen (TAN) during digestion [82]. For a successful AD process, the inhibitory effect of ammonia (threshold value of 200 mg/L) as well as the low C-N ratio of CM must be overcome as it may cause volatile fatty acid (VFA) to accumulate and inhibit microbial activities [16, 76, 82, 83]. Air stripping is a pretreatment technique to get rid of ammonia from CM wastewater [74]. TAN inhibition can be reduced by feeding the system with feedstock containing low TS [65]. For a stable AD performance and a balanced nutrient, mono-digestion of CM is often frown at. Anaerobic co-digestion of CM with other feedstock is mostly carried out by researchers as alternative method of solving the ammonia problem [84]. Example is co-digestion of FW, goat manure and CM and co-digestion of ethanol plant effluent with CM [64, 82] among others.

Amongst all agricultural activities, the poultry sector is one capable of generating huge amount of organic waste [85]. Livestock farmers, especially those handling poultry birds like geese, ducks, turkey, chicken, guinea fowl, quail, ostrich and pigeon in poultry houses disposes off the waste generated from these animals on the environment. Chicken waste are often applied on agricultural land as manure or compost as a traditional treatment approaches, dumped at landfill, or incinerated, contaminating the environment in the process [71, 86]. For instance, too much of nitrogen and phosphorus in CM results in eutrophication during landfill and composting [74]. In addition, chicken waste provides a breeding environment for flies and parasites, pathogen release, eutrophication of surface waters, threat to local air quality when used as fertilizer, pollution to soil, health risks and groundwater contamination [79, 86–88]. Its effect on soil properties is classified into three, and includes physical, chemical, and biological effects. CM in solid or liquid phases used on irrigated soils risks increased soil and groundwater salinity, excessive nitrate leaching to ground water as chemical effect. Biologically, problems arising are; introduction of pathogens, deterioration of soil carbon, and decreasing populations of desirable microbes [71, 82, 88]. The soil physical property like structure/texture may also be affected [89]. Improper disposal of CM waste must be addressed to mitigate its effect on the ecosystem. CM should be pre-process or pretreated by thermo-chemical and/or physical processing technologies like torrefaction, ozone treatment, re-feeding to animals, composting, steam treatment, drying, ozone treatment, pyrolysis, esterification, gasification, co-gasification, fermentation or digestion, combustion and co-combustion [82, 90]. In [91], it was affirmed that, combustion can be a viable and dependable way to treat CM, principally when coupled with energy recovery.

3.4. Biogas Potential of Feedstock Constituents

Anaerobic conversion of organic material is defined by [57] in Equation 2.

$$

\text{Biomass} + H_2O

\rightarrow

CH_4 + NH_3 + H_2S + \text{Heat}

+ \text{undecomposed organic matter}

\tag{2}

$$

Typically, biomass contains carbon, hydrogen, oxygen, nitrogen and Sulphur, depending on the feedstock in varying amount. The empirical formula is simply, CaHbOcNdSe, where a, b, c, d and e are atomic numbers of the respective elements in the biomass. The degradable fraction of FWs mainly includes carbohydrates (C6H12O6), proteins (C13H25O7N3S), and lipids (C12H24O6) [31]. Lipids are found in meat processing byproducts, agro-industrial residues and fatty wastewater; carbohydrate are found in agricultural waste and in organic fraction of municipal solid waste; while proteins are found in waste from slaughterhouses and meat processing industry [64]. Biogas potential of feedstock constituents can be predicted by employing Buswell’s empirical formula of Equation 3 [6, 15, 27, 29, 62]

$$

\begin{aligned}

\left(

\frac{4a – b – 2c + 3d + 2e}{4}

\right) H_2O

+ C_a H_b O_c N_d S_e

\;\rightarrow\;& \\[6pt]

\left(

\frac{4a + b – 2c – 3d – 2e}{8}

\right) CH_4

&+ \left(

\frac{4a + b + 2c + 3d + 2e}{8}

\right) CO_2 \\[6pt]

&+ d\,NH_3

+ e\,H_2S

\end{aligned}

\tag{3}

$$

Equation 3 is the modified form of Equation 2. Equation 2 is mainly used to assess methane production and to stabilize the digesting system, which can also be achieved using stoichiometry in Table 4 [67].

Table 4. Stoichiometry of biogas potential determination from various feedstock components [30, 62]

Feedstock | Methane Formation Stoichiometry | Methane Concentration (%) |

Carbohydrate | (𝐶6𝐻10𝑂5)𝑛 + 𝑛𝐻2𝑂 → 3𝑛𝐶𝐻4 +3𝑛𝐶𝑂2 | 50 |

Lipid | 𝐶50𝐻90𝑂6 + 24.5𝐻2𝑂 → 34.75𝐶𝐻4 +15.25𝐶𝑂2 | 69.5 |

Protein | 𝐶16𝐻24𝑂5𝑁4 +14.5𝐻2𝑂 → 8.25𝐶𝐻4 +3.75𝐶𝑂2 +4𝑁𝐻4+ +4𝐻𝐶𝑂3− | 68.8 |

When the elemental composition is known, the theoretical methane production can be calculated using Equation 3. When both the elemental composition and the proportion of carbohydrates, proteins, and fats are not known, the theoretical methane yield can also be calculated from the COD of the feedstock using reaction 4 [27]:

𝐶𝐻4 +2𝑂2 →𝐶𝑂2+2𝐻2𝑂 (4)

From Equation 4, 2-kmols of O2 (or 64 kg COD) are needed for the complete oxidation of 1-kmol of methane, so 1 kg COD is equivalent to 1/64-kmol of methane or 0.35 m3 CH4 at standard temperature and pressure [27].

3.5. Anaerobic Codigestion (AcoD)

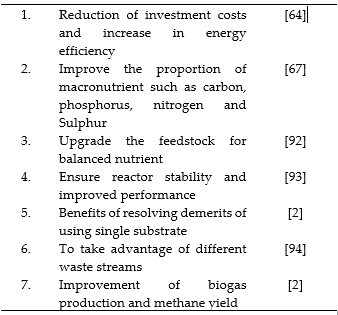

Multiple degradable waste may be mixed in the same digester at various combinations and fractions to increase biogas yield [1, 62]. This is called anaerobic codigestion (AcoD). AcoD comes with the merits shown in Table 5.

Table 5: Merits of Anaerobic Codigestion

S/No. | Advantage | References |

To optimize the AcoD process of biogas production technique, biodegradability, chemical composition, bioavailability, operational parameters (temperature, pH, loading rate etc), bioaccessibility, addition of nanoparticles, thermodynamic and kinetic model and characterization of substrates are crucial parameters to consider [2]. Enhancement of biogas output is divided into upstream, mainstream and downstream processes [85]. Upstream approaches including fungal pretreatment, enzymatic, microaeration, composting, and ensiling have been employed prior to AD to improve biogas yield and productivity [79]. Mainstream approaches include bioaugmentation, AcoD and integrated biogas production techniques while the downstream approaches focuses on biological removal of CO2, impurities and H2S [94]. Table 6 and 7 is almost a demonstration of how AcoD of multiple feedstock will increase methane yield.

Table 6: Methane Yield from AcoD of MSW with Agricultural waste [4]

Substrate types | Methane yield (m3/kg VS) |

MSW and activated sludge MSW and sewage sludge Hydroseparated MSW and sewage sludge MSW and activated sludge MSWand leachate MSW and pig manure MSW and cattle manure MSW and rice straw | 0.376 0.395 0.333 0.287 0.232 0.377 0.443 0.403 |

In several text, methane and biogas yield are used synonymously or interchangeably, especially in kinetic equations to estimate unknown parameters. The units of biogas and methane yield reported in Table 6 and 7 can be converted using equation given by [102] to other units. Either algae or lignocellulosic biomass that limits hydrolysis stage of AD can be codigested with animal manures rich in C/N ratio to avoid the resurgence of NH3 [12, 40, 103]. To practicalize this in FW, mixing fat-rich materials with carbohydrate-rich materials (fast degradable and slowly degradable specie) are advantageous in microorganism enrichment, nutrition balance, increase in stability, reduction in the accumulation of inhibitors, high efficiency of biogas production and methane yield [2, 41].

Table 7. Biogas Yield of Chicken Manure and Other Substrates

Feedstock | Biogas yield (mL/g VS) | Reference |

CM + algae | 332 | [95] |

CM + cardboard waste | 319.62 | [96] |

CM + energy crop residue | – | [97] |

FW, goat, & CM | 80-109 | [81] |

Oil refinery wastewater + CM | 194.02 | [98] |

Chicken processing waste, seagrass and Miscanthus | 400 | [76] |

Durian shell, chicken, dairy and pig manures | 224.8 | [100] |

CM + poppy straw | – | [101] |

Corn stover + CM | 218.8 | [71] |

Replacing the feedstock should be applied with caution, though, it does not necessarily have negative impacts on biogas production. Frankly, when the substrate type changes, the microbial communities need to adapt to the new environment and conditions [104]. Bioaugmentation is a type of strategy of adding specific microbial cultures to a biological system to improve the operational function by manipulating the microbial consortium [105]. This is based on the belief that slow degradation is caused by the absence or low populations of microorganisms responsible for the particular degradation step [16]. Bioaugmentation has been investigated in lab-scale digesters [105]; however, full-scale applications are still limited.

4. Biogas Production Across the Globe

Further growth in global market value of biogas is foreseen to rise before 2025 as countries poor in developing biogas plants are investing in the technology [89, 106]. According to [56], there are around 35 million installed biogas plant across the globe. The development in biogas production across continents can be visualized.

4.1. Europe and North America

Europe has an energy target they hope to achieve; hence, majority of World’s biogas plants are in Europe [10, 62, 107]. Europe can boost of 20,000 plants [108]. The continent also lead in electricity generation from biogas [29]. Out of the 20,000 plants mentioned, (17,662 plants – 88%) is exploited for electricity generation [109]. The capacity of the plants for biogas in 2017 was 10.9 million tonnes, currently around 200 billion m3 annually and projected to reach 18-20 billion m3 by 2030 [9, 46, 48]. In areas of research, commercial utilization and industrial uses, number of plants rises from 3,700 agricultural biogas plants in 2007 to (7.2 thousand) in 2017 in Germany, and considered highest, producing 6.7-10.9 million tonnes of biogas in 2017 due to federal government support [9, 11, 46, 49, 95]. All this progress is a result of the shift from energy crops used to substrate [7, 51]. One of these substrates is CM [105]. Italy use wheat as feedstock for biogas production while Belgium has a bio-plant capable of handling 58,000 tons of waste yearly [40, 52]. In Sweden, CSTR type biomass plants are widely used to process FW to biogas and subsequently into biomethane [28, 96]. Main feedstock is sewage and landfills, producing the largest amount of biomethane for use in buses and cars [9, 11, 97]. Twelve thousand vehicles were estimated to have been fueled in 2007 with upgraded biogas the world over [25]. France main feedstock are agricultural, wastewater, FW and industrial beverages processed in about 309 plants [20]. Enlargement of biogas plants to 5-10 times their original volume is the common trend now in Austria [107]. Centralized biogas plants and farm biogas plants are the two classes of biogas plants in Denmark [110]. Apart from single substrate plants, Denmark are the country most-utilizing multiple substrates to co-digest feedstock for diverse function [1, 49]. Waste paper and the use of wheat straw obtained at Newcastle University, had been studied for production of biogas in the United Kingdom (UK) [53, 111]. Switzerland is characterized for installing large-scale biogas plants, accounting for 82%, largely from manure and other agricultural feedstock [50, 89]. Poland’s substrate for large-scale plants are slurry, pork, maize silage and distillery effluent [112]. Figure 2.3 depicts two biogas plants in Poland that uses sewage and agricultural materials as feedstock. Efficacy of steam explosion physical pretreatment method is widely accepted at the moment in Czech Republic [20]. Norway developed the world biggest liquid biogas plant [67]. Scotland explored waste paper collected from School of Computing and Engineering at the University of West of Scotland (UWS) as feedstock [60].

North America (countries like US, Canada, Mexico and Brazil) had thousands of agricultural biogas plants [10]. United States has 2,200 biogas systems processing 70 million tons of organic matter and 0.2 billion kWh-1030 GWh of electricity annually [11, 42, 100]. Biogas had been utilized as bus fleet fuel for over 180, 000 buses in Brazil, the largest percentage of it coming from cattle manure, producing 584 billion m3/y of biogas [11, 101]. The Brazilian Association of Biogas and Methane is playing significant role in that direction [113]. Federal University of Fronteira Sul in Brazil was investigated by [77] looking at the potential of corn stalk for biogas synthesis.

Population of animal in Asia (countries including, India, China, Indonesia, Malaysia, Iran, Singapore, Japan, etc ) cannot be compared with any region [20]. As regards biogas, the technology all started from China as mentioned earlier [19]. They can boost of 100,000 modern biogas plants generating 50 billion m3 of biogas yearly, 3000 MW of electricity being the biggest in Asia [11, 62, 104].

In 2015, China had produced 787.4 million tons of crop straw, mostly wheat straw, amounting to 130 million tons in 2016 [45, 107]. More than 35,000 biogas plants by Indian Government’s support had been built so far, plus 100,000 used for cooking in Indian households [4]. Indonesia, is currently the 4th most populous country in the world widely building fixed dome digesters for Small and Medium Enterprises (SMEs) for farmers utilizing water hyacinth, animal waste and palm oil [6, 18, 22, 54]. Indonesia is the largest producer of palm oil in the world in which POME is the major feedstock followed by Malaysia [114–116]. Fortunately, apart from POME, Malaysians make use of low cost animal waste as alternative AD feed [20]. There are 1040 tons/day of MSW and 152 tons/day of green waste that could be run in a 550 tons/day AD plant capacity in Isfahan, Iran [47].

Major feed to biogas industries in Singapore are sewage sludge, FW, animal manure and horticulture wastes [92]. Japan is the only country using thermophilic approach in Asia [4]; other Asian nations like Korea, Cambodia, Vietnam, Nepal and Bangladesh’s adoption for domestic installations is rising. Pigs, water buffalo and cattle, numbering 30 million are the sources of livestock manure with potential for biogas production in Vietnam [118]. Nepal being in front in installation rate, boost of approximately 330,000 households [11]. Biogas production potential in Bangladesh is around 17000 million m3 used mainly for cooking purposes [11, 20]. South American nations are hardly mentioned in the literature with regards to biogas synthesis. A pocket of publications was recorded by [55] on the utilization of corn stover, a lignocellulosic waste in Santiago, Chile.

Several biogas plants are being in operation in Africa [4, 20]. To supply farm houses with energy, Ducellier and Isman build simple biogas machines in Algeria between 1930 and 1940, an act that signals the beginning or introduction of biogas technology in Africa [103]. Two notable large scale plants projects that are operational in Africa is the GOPDC-Ghana and PRESCO PLC-Nigeria [119]. Biogas potential in Mauritania is 520 106 m3/year and 258.7 (±125.8) 106 m3/year while in Egypt these plants are mostly buried underground [20, 119]. Ethiopia employ fixed dome bioreactor in about 4500 household utilizing kitchen waste [24, 120]. Data on biogas application in Somalia is scanty because only about 1% of communities in the 43rd largest country in the world consume the gaseous fuel according to [121]. Main feedstock for Sudan’s 200 installed biogas facility is animal and agricultural waste according to a 2005 figure [36]. Summarily, East and North Africa could boost of 3.2 million m3/h of biogas production. In 2017, of the 700 biogas plants in South Africa, only 300 was reported to be in operation [56]. In 2021, [37] reported a lower figure (200 digesters) of working bioreactors in South Africa (a 66.7% further reduction).

Nigeria’s biogas potential in 1999 was 1382 m3/yr – before then (1995), the pioneer plants build by the Sokoto Energy Research Center (SERC) in Zaria has the capacity of 10 m3 of biogas; an 18 m3 plant constructed by the Federal Institute of Industrial Research Oshodi (FIIRO) at Ojokoro Ifelodun Piggery Farm, Lagos in 1996; Mayflower School Ikene in Ogun State; and at Usman Danfodio University Sokoto, most of which are still at research stage or non-operational [122–125]. Undoubtedly, enormous amount of solid waste (32 million tonnes) is generated in Nigeria, but real effort had not been made by government to build a biogas plant to benefit from any of its products; atleast to meet the demands of millions living without electricity in the nation [45, 124, 126]. One notable government interest was the setting up of a biogas plant at Karu Abattoirs, Nasarawa state by the Federal Capital Territory (FCT) Administration in Nigeria [124]. However, several studies had been done on a bench-scale biodigester in Polytechnics and Universities in Nigeria for research purposes only [117, 126]. Biogas plants in some academic institutions in Nigeria are Usman Danfodio University Biogas Plant, Obafemi Awolowo University Biogas Plant and patent University of Ibadan Prototype Plant [45, 122, 127]. Other University related research and installation of the plant are reported elsewhere by [19, 36, 59, 60, 75, 128]. The trading, usage and construction of biodigester came much earlier in Kenya (1948) compared to Nigeria when Tim Hutchinson built the 1st biodigester that uses coffee pulp in the country. The country is also in the frontline in the gas manufacture in Africa overseeing the construction of 11,529 plants through the Africa Biogas Partnership Programme (ABPP) between 2009-2013 [43, 129]. In 2013, the ABPP built 70,000 biogas reactors in six member countries of Uganda, Senegal, Kenya, Burkina Faso, Tanzania and Ethiopia [37]. Tanzania developed their first plant in 1950s, making them third in Africa base on literature consulted after Algeria and Kenya [36].

5. Conclusion

Between 2000-2005, Nigeria is the country with the highest deforestation rate in the world and ranks 8 in methane emission, as they consume 46 million tonnes of wood and 3.2 million tonnes of charcoal for cooking as reported by [61, 129, 130]. Biogas plant development for use as cooking gas will go a long way in reducing the over-dependence on firewood, thereby checkmating desert encroachment in sub-Saharan Africa. Because biogas can be produced from hundreds of biowaste materials, most of them have not been studied (kinetic model-wise) in order to optimize their production. In the same context, there are too many of these biogas models (e.g. Chen & Hashimoto, Logistic, Bi-logistic, modified Gompertz, First-Order, modified First-Order, Richards, Biogas Production Kinetic (BPK), Transference function model, Cone, Transfert, Proposed model by [131] and Fitzhugh) to capture the multitude of feedstock in nature plus the variety of reactor types available and the dynamic operating conditions involved. Regression remains the most used chemical engineering analysis tool to explain these models used for a selected single or multiple feedstock [132].

Africa produces and utilizes less biogas compared to Europe and Asia as only few plants had been built for AD of feedstock in recent years. It is therefore recommended that Africa, increase the harnessing of the abundant waste generated annually from the continent to meet some of her challenges, especially in areas of electricity generation for its accelerated development. Since energy consumption has skyrocketed, the speculation, that global energy demand will increase by 50% in 2050 might be credible [42, 133] and surplus will be achieved to counter shortages if more countries key into biogas plant development. This work further aims at increasing research on feedstock utilization for the production of biogas as well as the application of kinetics to facilitate biogas plant design and optimization using different feedstock, most abundant in different countries. Biogas digesters are presumed to last for 100 years. Despite this merit, adoption and implementation of biogas projects in developing countries are hindered majorly due to resistance to change, inadequate research, training and expertise in the technology, lack of investment incentives and trade, insufficient funding and lack of policy, strategy and regulations.

- O. Khayal, “Main types and applications of biogas plants,” Nile Valley University, pp. 1–11, 2019, doi:10.13140/RG.2.2.32559.69287.

- K. Hagos et al., “Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives,” Renewable and Sustainable Energy Reviews, vol. 76, pp. 1485–1496, 2017, doi:http://dx.doi.org/10.1016/j.rser.2016.11.184.

- I. A. Raja, S. Wazir, “Biogas production: The fundamental processes,” Universal Journal of Engineering Science, vol. 5, no. 2, pp. 29–37, 2017, doi:10.13189/ujes.2017.050202.

- M. R. Atelge et al., “Biogas production from organic waste: Recent progress and perspectives,” Waste and Biomass Valorization, vol. 11, pp. 1–22, 2018, doi:10.1007/s12649-018-00546-0.

- J. Kainthola, A. S. Kalamdhad, V. V Goud, “A review on enhanced biogas production from anaerobic digestion of lignocellulosic biomass by different enhancement techniques,” Process Biochemistry, vol. 84, pp. 81–90, 2019, doi:10.1016/j.procbio.2019.05.023.

- A. M. Uche et al., “Design and construction of fixed dome digester for biogas production using cow dung and water hyacinth,” African Journal of Environmental Science and Technology, vol. 14, no. 1, pp. 15–25, 2020, doi:10.5897/AJEST2019.2739.

- I. Koniuszewska et al., “Intensification of biogas production using various technologies: A review,” International Journal of Energy Research, vol. 44, no. 8, pp. 6240–6258, 2020, doi:10.1002/er.5338.

- N. Sawyerr et al., “An overview of biogas production: Fundamentals, applications and future research,” International Journal of Energy Economics and Policy, vol. 9, no. 2, pp. 105–116, 2019, doi:10.32479/ijeep.7375.

- R. L. Granado et al., “Technology overview of biogas production in anaerobic digestion plants: A European evaluation of research and development,” Renewable and Sustainable Energy Reviews, vol. 80, pp. 44–53, 2017, doi:10.1016/j.rser.2017.05.079.

- B. Bharathiraja et al., “Biogas production – A review on composition, fuel properties, feed stock and principles of anaerobic digestion,” Renewable and Sustainable Energy Reviews, vol. 90, pp. 570–582, 2018, doi:10.1016/j.rser.2018.03.093.

- T. Chowdhury et al., “Latest advancements on livestock waste management and biogas production: Bangladesh’s perspective,” Journal of Cleaner Production, vol. 272, no. 122818, pp. 1–20, 2020, doi:https://doi.org/10.1016/j.jclepro.2020.122818.

- S. A. Neshat et al., “Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production,” Renewable and Sustainable Energy Reviews, vol. 79, pp. 308–322, 2017, doi:10.1016/j.rser.2017.05.137.

- M. Parsaee et al., “A review of biogas production from sugarcane vinasse,” Biomass and Bioenergy, vol. 122, pp. 117–125, 2019, doi:10.1016/j.biombioe.2019.01.034.

- A. Wu et al., “A spreadsheet calculator for estimating biogas production and economic measures for UK-based farm-fed anaerobic digesters,” Bioresource Technology, vol. 220, pp. 479–489, 2016, doi:10.1016/j.biortech.2016.08.103.

- N. Sahu et al., “Evaluation of biogas production potential of kitchen waste in the presence of spices,” Waste Management, vol. 70, pp. 236–246, 2017, doi:10.1016/j.wasman.2017.08.045.

- M. Westerholm, A. Schnürer, Microbial responses to different operating practices for biogas production systems (Uppsala, Sweden: InTech Open, 2019).

- Z. Lenkiewicz, M. Webster, “How to convert organic waste into biogas: A step-by-step guide.” wasteaid.org.uk/toolkit . (accessed: 14-Aug-2021).

- M. Khalil et al., “Waste to energy technology: The potential of sustainable biogas production from animal waste in Indonesia,” Renewable and Sustainable Energy Reviews, vol. 105, pp. 323–331, 2019, doi:10.1016/j.rser.2019.02.011.

- Y. Lahlou, Design of a biogas pilot unit for Al Akhawayn University (School of Science and Engineering, 2017).

- M. M. Ali et al., “Mapping of biogas production potential from livestock manures and slaughterhouse waste: A case study for African countries,” Journal of Cleaner Production, vol. 256, no. 120499, pp. 1–18, 2020, doi:https://doi.org/10.1016/j.jclepro.2020.120499.

- Martina Pilloni and Tareq Abu Hamed, “Small-size biogas technology applications for rural areas in the context of developing countries,” in Anaerobic digestion in built environments, ed Anna Sikora (IntechOPen, 2021), 24, doi:http://dx.doi.org/10.5772/intechopen.96857.

- M. A. Fahriansyah, Sriharti, “Design of conventional mixer for biogas digester,” IOP Conference Series: Earth and Environmental Science, pp. 1–8, 2019, doi:10.1088/1755-1315/277/1/012017.

- IRENA, “Measuring small-scale biogas capacity and production.” Abu Dhabi, United Arab Emirates, 2016.

- E. W. Gabisa, S. H. Gheewala, “Potential, environmental, and socio-economic assessment of biogas production in Ethiopia: The case of Amhara regional state,” Biomass and Bioenergy, vol. 122, pp. 446–456, 2019, doi:10.1016/j.biombioe.2019.02.003.

- A. F. Akintade, “Biogas a viable source of energy: Case study, Nigeria,” (Centria University of Applied Sciences, 2021).

- O. Raymond, U. Okezie, “The significance of biogas plants in Nigeria’s energy strategy,” Journal of Physical Sciences and Innovation, vol. 3, pp. 11–17, 2011.

- R. J. Patinvoh et al., “Innovative pretreatment strategies for biogas production,” Bioresource Technology, vol. 224, pp. 13–24, 2016, doi:10.1016/j.biortech.2016.11.083.

- S. M. A. Abuabdou et al., “A review of anaerobic membrane bioreactors (AnMBR) for the treatment of highly contaminated land fill leachate and biogas production: Effectiveness, limitations and future perspectives,” Journal of Cleaner Production, vol. 255, no. 120215, pp. 1–12, 2020, doi:10.1016/j.jclepro.2020.120215.

- M. C. Caruso et al., “Recent updates on the use of agro-food waste for biogas production,” Applied Sciences, vol. 9, no. 6, pp. 1–29, 2019, doi:10.3390/app9061217.

- M. Westerholm, T. Liu, A. Schnürer, “Comparative study of industrial-scale high-solid biogas production from food waste: Process operation and microbiology,” Bioresource Technology, vol. 304, pp. 122–981, 2020, doi:10.1016/j.biortech.2020.122981.

- S. Mirmohamadsadeghi et al., “Biogas production from food wastes: A review on recent developments and future perspectives,” Bioresource Technology Reports, vol. 7, no. 100202, pp. 1–37, 2019, doi:10.1016/j.biteb.2019.100202.

- M. A. Aziz et al., “Recent advances on palm oil mill effluent ( POME ) pretreatment and anaerobic reactor for sustainable biogas production,” Renewable and Sustainable Energy Reviews, vol. 119, no. 109603, pp. 1–31, 2019, doi:https://doi.org/10.1016/j.rser.2019.109603.

- E. I. Dhimain, S. C. Izah, “Potential of biogas production from palm oil mills effluent in Nigeria,” Sky Journal of Soil Science and Environmental Management (SJSSEM), vol. 3, no. 5, pp. 50–58, 2014.

- M. Bakraoui et al., “Biogas production from recycled paper mill wastewater by UASB digester: Optimal and mesophilic conditions,” Biotechnology Reports, vol. 25, pp. 1–8, 2020, doi:10.1016/j.btre.2019.e00402.

- V. J. Brown, “Biogas: A bright idea for Africa,” Environmental Health Perspectives, vol. 114, no. 5, pp. 300–303, 2006.

- A. M. Mshandete, W. Parawira, “Biogas technology research in selected sub-Saharan African countries-A review,” African Journal of Biotechnology, vol. 8, no. 2, pp. 116–125, 2009.

- R. F. T. Tagne et al., “Technologies, challenges and perspectives of biogas production within an agricultural context: The case of China and Africa,” Environment, Development and Sustainability, vol. 23, pp. 14799–14826, 2021, doi:https://doi.org/10.1007/s10668-021-01272-9.

- A. I. Aigbodion et al., “Viability of biogas production from manure/biomass in Nigeria using fixed dome digester,” Universal Journal of Agricultural Research (UJAR), vol. 6, no. 1, pp. 1–8, 2018, doi:10.13189/ujar.2018/060101.

- E. M. M. Esteves et al., “Life cycle assessment of manure biogas production: A review,” Journal of Cleaner Production, vol. 219, pp. 411–423, 2019, doi:10.1016/j.jclepro.2019.02.091.

- Ł. Małgorzata, J. Frankowski, “The biogas production potential from silkworm waste,” Waste Management, vol. 79, pp. 564–570, 2018, doi:10.1016/j.wasman.2018.08.019.

- K. Chaump et al., “Leaching and anaerobic digestion of poultry litter for biogas production and nutrient transformation,” Elsevier, vol. 84, pp. 413–422, 2018, doi:10.1016/j.wasman.2018.11.024.

- H. Wang et al., “Effect of addition of biogas slurry for anaerobic fermentation of deer manure on biogas production,” Energy, vol. 165, pp. 411–418, 2018, doi:10.1016/j.energy.2018.09.196.

- C. Mulinda, Q. Hu, K. Pan, “Dissemination and problems of African biogas technology,” Energy and Power Engineering, vol. 5, pp. 506–512, 2013, doi:http://dx.doi.org/10.4236/epe.2013.58055.

- M. N. Usman, M. A. Suleiman, M. I. Binni, Anaerobic digestion of agricultural wastes: A potential remedy for energy shortfalls in Nigeria, vol. 4, no. 1, (Scholarena, 2021).

- M. B. Biodun, O. S. I. Fayomi, J. O. Okeniyi, “The possibility of biogas production in Nigeria from organic waste material: A review,” International Conference on Engineering for Sustainable World (ICESW 2020): Material Science and Engineering, vol. 1107, no. 012166, pp. 1–9, 2020, doi:10.1088/1757-899X/1107/1/012166.

- T. M. Simeon, “Techno-economic analysis of a model biogas plant for agricultural applications: A case study of the Concordia Farms Limited, Nonwa, Tai, Rivers State,” (University of Nigeria, Nsukka, 2009).

- S. M. M. N. Dehkordi et al., “Investigation of biogas production potential from mechanical separated municipal solid waste as an approach for developing countries (case study: Isfahan-Iran),” Renewable and Sustainable Energy Reviews, vol. 119, no. 109586, pp. 1–12, 2020, doi:10.1016/j.rser.2019.109586.

- J. Liebetrau et al., Potential and utilization of manure to generate biogas in seven countries (IEA Bioenergy Task 37, 2021).

- T. M. Thompson, B. R. Young, S. Baroutian, “Advances in the pretreatment of brown macroalgae for biogas production,” Fuel Processing Technology, vol. 195, no. 106151, pp. 1–12, 2019, doi:10.1016/j.fuproc.2019.106151.

- S. Achinas, G. J. W. Euverink, “Elevated biogas production from the anaerobic co-digestion of farmhouse waste: Insight into the process performance and kinetics,” Waste Management & Research, vol. 37, no. 12, pp. 1240–1249, 2019, doi:10.1177/0734242X19873383.

- C. P. C. Bong et al., “The characterisation and treatment of food waste for improvement of biogas production during anaerobic digestion– A review,” Journal of Cleaner Production, vol. 172, pp. 1545–1558, 2017, doi:10.1016/j.jclepro.2017.10.199.

- S. Tanigawa, “Fact Sheet | Biogas: Converting Waste to Energy Tags / Keywords.” www-eesi-org-papers-view-fact-sheet-biogasconverting-waste-to-energy . (accessed: 14-Aug-2021).

- N. I. H. Abdul Aziz, M. M. Hanafiah, M. Y. M. Ali, “Sustainable biogas production from agrowaste and effluents – A promising step for small-scale industry income,” Renewable Energy, vol. 132, pp. 363–369, 2018, doi:10.1016/j.renene.2018.07.149.

- Q. Yu et al., “A review of crop straw pretreatment methods for biogas production by anaerobic digestion in China,” Renewable and Sustainable Energy Reviews, vol. 107, pp. 51–58, 2019, doi:10.1016/j.rser.2019.02.020.

- V. Wyman et al., “Lignocellulosic waste valorisation strategy through enzyme and biogas production,” Bioresource Technology, vol. 247, pp. 402–411, 2018, doi:10.1016/j.biortech.2017.09.055.

- F. Kemausuor, M. S. Adaramola, J. Morken, “A review of commercial biogas systems and lessons for Africa,” Energies, vol. 11, no. 2984, pp. 1–21, 2018, doi:10.3390/en11112984.

- S. K. Srivastava, “Advancement in biogas production from the solid waste by optimizing the anaerobic digestion,” Waste Disposal & Sustainable Energy, vol. 2, no. 2, pp. 85–103, 2020, doi:10.1007/s42768-020-00036-x.

- E. P. Akhator, D. I. Igbinomwanhia, A. I. Obanor, “Potentials for commercial production of biogas from domestic food waste generated in Benin Metropolis, Nigeria,” Journal of Applied Sciences and Environmental Management (JASEM), vol. 20, no. 2, pp. 369–373, 2016, doi:http://dx.doi.org/10.4314/jasem.v20i2.19.

- Z. Kong et al., “Large pilot-scale submerged anaerobic membrane bioreactor for the treatment of municipal wastewater and biogas production at 25◦C,” Bioresource Technology, vol. 319, pp. 1–12, 2021, doi:10.1016/j.biortech.2020.124123.

- C. Rodriguez et al., “Mechanical pretreatment of waste paper for biogas production,” Waste Management, vol. 68, pp. 157–164, 2017, doi:10.1016/j.wasman.2017.06.040.

- F. O. Olanrewaju et al., “Bioenergy potential in Nigeria,” Chemical Engineering Transactions, vol. 74, pp. 61–66, 2019.

- G. Mancini et al., “Increased biogas production from wheat straw by chemical pretreatments,” Renewable Energy, vol. 119, pp. 608–614, 2018, doi:10.1016/j.renene.2017.12.045.

- A. M. A. Mohammed, F. M. A. Kabbashi, H. K. A. Hamad, “Production of biogas from biomedical waste (blood),” (Sudan University of Science and Technology, 2017).

- D. Elalami et al., “Pretreatment and co-digestion of wastewater sludge for biogas production: Recent research advances and trends,” Renewable and Sustainable Energy Reviews, vol. 114, no. 109287, pp. 1–23, 2019, doi:10.1016/j.rser.2019.109287.

- O. Tomori, “Feasibility study of a large scale biogas plant in Lagos, Nigeria,” (Murdoch University of Western Australia, 2012).

- A. Nsair et al., “Operational parameters of biogas plants: A review and evaluation study,” Energies, vol. 13, no. 15, pp. 1–27, 2020, doi:10.3390/en13153761.

- S. Sarker et al., “A review of the role of critical parameters in the design and operation of biogas production plants,” Applied Sciences, vol. 9, no. 9, pp. 1–38, 2019, doi:10.3390/app9091915.

- S. K. Pramanik et al., “The anaerobic digestion process of biogas production from food waste: Prospects and constraints,” Bioresource Technology Reports, vol. 8, pp. 1–38, 2019, doi:10.1016/j.biteb.2019.100310.

- S. Sarto, R. Hildayati, I. Syaichurrozi, “Effect of chemical pretreatment using sulfuric acid on biogas production from water hyacinth and kinetics,” Renewable Energy, vol. 132, pp. 335–350, 2019, doi:10.1016/j.renene.2018.07.121.

- V. A. Mazur et al., “Agroecological prospects of using corn hybrids for biogas production,” Agronomy Research, vol. 18, no. 1, pp. 177–182, 2020, doi:https://doi.org/10.15159/ar.20.016.

- H. Gebretsadik, S. Mulaw, G. Gebregziabher, “Qualitative and quantitative feasibility of biogas production from kitchen waste,” American Journal of Energy Engineering, vol. 6, no. 1, pp. 1–5, 2018, doi:10.11648/j.ajee.20180601.11.

- H. T. T. Nong et al., “Development of sustainable approaches for converting the agro-weeds Ludwigia hyssopifolia to biogas production,” Biomass Conversion and Biorefinery, pp. 1–9, 2020, doi:https://doi.org/10.1007/s13399-020-01083-4.

- S. Wacławek et al., “Disintegration of wastewater activated sludge (WAS) for improved biogas production,” Energies, vol. 12, no. 21, pp. 1–15, 2019, doi:10.3390/en12010021.

- W. Cao et al., “Hydrogen production from supercritical water gasification of chicken manure,” International Journal of Hydrogen Energy, pp. 1–10, 2016, doi:10.1016/j.ijhydene.2016.09.031.

- A. Abraham et al., “Pretreatment strategies for enhanced biogas production from lignocellulosic biomass,” Bioresource Technology, vol. 301, no. 122725, pp. 1–13, 2020, doi:10.1016/j.biortech.2019.122725.

- S. Ali et al., “Evaluating the co-digestion effects on chicken manure and rotten potatoes in batch experiments,” International Journal of Biosciences (IJB), vol. 10, no. 6, pp. 150–159, 2017, doi:10.12692/ijb/10.6.150-159.

- B. Venturin et al., “Effect of pretreatments on corn stalk chemical properties for biogas production purposes,” Bioresource Technology, vol. 266, pp. 1–36, 2018, doi:10.1016/j.biortech.2018.06.069.

- S. Mirmohamadsadeghi et al., “Pretreatment of lignocelluloses for enhanced biogas production: A review on influencing mechanisms and the importance of microbial diversity,” Renewable and Sustainable Energy Reviews, vol. 135, no. 110173, pp. 1–19, 2021, doi:10.1016/j.rser.2020.110173.

- M. Tabatabaei et al., “A comprehensive review on recent biological innovations to improve biogas production, Part 1: Upstream strategies,” Renewable Energy, vol. 146, pp. 1204–1220, 2019, doi:https://doi.org/10.1016/j.renene.2019.07.037.

- A. A. Rajput, C. Visvanathan, “Effect of thermal pretreatment on chemical composition, physical structure and biogas production kinetics of wheat straw,” Journal of Environmental Management, vol. 221, pp. 45–52, 2018, doi:10.1016/j.jenvman.2018.05.011.

- S. P. Lohani et al., “Anaerobic co-digestion of food waste, goat and chicken manure for sustainable biogas production,” International Journal of Energy Applications and Technologies, vol. 7, no. 4, pp. 120–125, 2020, doi:10.31593/ijeat.748982.

- K. Dalk, A. Ugurlu, “Biogas production from chicken manure at different organic loading rates in a mesophilic-thermopilic two stage anaerobic system,” Journal of Bioscience and Bioengineering, vol. xx, no. xx, pp. 1–8, 2015, doi:10.1016/j.jbiosc.2015.01.021.

- N. Duan et al., “Performance evaluation of mesophilic anaerobic digestion of chicken manure with algal digestate,” Energies, vol. 11, no. 1829, pp. 1–11, 2018, doi:10.3390/en11071829.

- M. A. K. B. D. T. T. Onay, “Enhanced biogas production from chicken manure via enzymatic pretreatment,” Journal of Material Cycles and Waste Management, no. 0123456789, 2020, doi:10.1007/s10163-020-01039-w.

- T. Keskin et al., “The determination of the trace element effects on basal medium by using the statistical optimization approach for biogas production from chicken manure,” Waste and Biomass Valorization, vol. 0, no. 0, pp. 1–10, 2018, doi:10.1007/s12649-018-0273-2.

- W. Fuchs et al., “Tackling ammonia inhibition for efficient biogas production from chicken manure: Status and technical trends in Europe and China,” Renewable and Sustainable Energy Reviews, vol. 97, pp. 186–199, 2020, doi:10.1016/j.rser.2018.08.038.

- N. A. Noori, Z. Z. Ismail, “Process optimization of biogas recovery from giant reed (Arundo donax) alternatively pretreated with acid and oxidant agent: Experimental and kinetic study,” Biomass Conversion and Biorefinery, pp. 1–15, 2019, doi:https://doi.org/10.1007/s13399-019-00481-7.

- Y. Li et al., “Biogas production from co-digestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions,” Bioresource Technology, vol. 149, pp. 406–412, 2013, doi:http://dx.doi.org/10.1016/j.biortech.2013.09.091.

- M. Hassan et al., “Methane enhancement through co-digestion of chicken manure and oxidative cleaved wheat straw: Stability performance and kinetic modeling perspectives,” Energy, vol. 141, pp. 2314–2320, 2017, doi:https://doi.org/10.1016/j.energy.2017.11.110.

- Y. K. Li, X. M. Hu, L. Feng, “Characteristics of biogas production via high-temperature dry fermentation of chicken manure,” Applied Ecology and Environmental Research, vol. 18, no. 4, pp. 4883–4895, 2020, doi:http://dx.doi.org/10.15666/aeer/1804_48834895.

- D. Cheong, J. Kim, C. Lee, “Improving biomethanation of chicken manure by co-digestion with ethanol plant effluent,” International Journal of Environmental Research and Public Health, vol. 16, no. 5023, pp. 1–10, 2019, doi:10.3390/ijerph16245023.

- L. Zhang, K. Loh, J. Zhang, “Enhanced biogas production from anaerobic digestion of solid organic wastes: Current status and prospects,” Bioresource Technology Reports, vol. 5, pp. 280–296, 2019, doi:10.1016/j.biteb.2018.07.005.

- B. Shamurad et al., “Stable biogas production from single-stage anaerobic digestion of food waste,” Applied Energy, vol. 263, no. 114609, pp. 1–37, 2019, doi:http://dx.doi.org/10.17632/6wnfvkz6gb.1.

- M. Tabatabaei et al., “A comprehensive review on recent biological innovations to improve biogas production, Part 2: Mainstream and downstream strategies,” Renewable Energy, vol. 146, pp. 1392–1407, 2019, doi:https://doi.org/10.1016/j.renene.2019.07.047.

- A. Abdelhay, L. Al-Hasanat, A. Albsoul, “Anaerobic co-digestion of cattle manure and raw algae: Kinetic study and optimization of methane potential by RSM,” Pol. Journal of Environmental Studies, vol. 30, no. 2, pp. 1029–1037, 2021, doi:10.15244/pjoes/125523.

- S. Zhao et al., “Anaerobic co-digestion of chicken manure and cardboard waste: Focusing on methane production, microbial community analysis and energy evaluation,” Bioresource Technology, vol. 321, no. 12449, pp. 1–11, 2021, doi:https://doi.org/10.1016/j.biortech.2020.124429.

- N. A. D. Cahyono et al., “Anaerobic co-digestion of chicken manure with energy crop residues for biogas production,” IOP Conference Series: Earth and Environmental Science, pp. 765, 2021, doi:10.1088/1755-1315/765/1/012044.

- E. Mehryar et al., “Anaerobic co-digestion of oil refinery wastewater and chicken manure to produce biogas, and kinetic parameters determination in batch reactors,” Agronomy Research, vol. 15, no. 5, pp. 1983–1996, 2017, doi:https://doi.org/10.15159/AR.17.072.

- C. Li et al., “Assessment of regional biomass as co-substrate in the anaerobic digestion of chicken manure: Impact of co-digestion with chicken processing waste, seagrass and Miscanthus,” Biochemical Engineering Journal, pp. 1–38, 2016, doi:http://dx.doi.org/doi:10.1016/j.bej.2016.11.008.

- J. Shena et al., “Biogas production from anaerobic co-digestion of durian shell with chicken, dairy, and pig manures,” Energy Conversion and Management, pp. 1–10, 2018, doi:https://doi.org/10.1016/j.enconman.2018.06.099.

- A. Bayrakdar et al., “Biogas production from chicken manure: Co-digestion with spent poppy straw,” International Biodeterioration & Biodegradation, pp. 1–6, 2016, doi:http://dx.doi.org/10.1016/j.ibiod.2016.10.058.

- A. M. Abubakar, M. U. Yunus, “Reporting biogas data from various feedstock,” International Journal of Formal Sciences: Current and Future Research Trends (IJFSCFRT), vol. 11, no. 1, pp. 23–36, 2021, doi:10.5281/zenodo.6366775.

- C. C. Ngumah et al., “Biogas potential of organic waste in Nigeria,” Journal of Urban and Environmental Engineering (JUEE), vol. 7, no. 1, pp. 110–116, 2013, doi:10.4090/juee.2013.v7n1.110116.

- S. Theuerl, J. Klang, A. Prochnow, “Process disturbances in agricultural biogas production — Causes , mechanisms and effects on the biogas microbiome: A review,” Energies, vol. 12, no. 3, pp. 1–20, 2019, doi:10.3390/en12030365.

- W. Fuchs et al., “Tackling ammonia inhibition for efficient biogas production from chicken manure: Status and technical trends in Europe and China,” Renewable and Sustainable Energy Reviews, vol. 97, pp. 186–199, 2018, doi:10.1016/j.rser.2018.08.038.

- P. Baltrėnas, V. Kolodynskij, D. Urbanas, “Biogas production from chicken manure at different organic loadings using a special zeolite additive (ZeoVit sorbent),” Journal of Renewable Sustainable Energy, vol. 11, no. 063101, pp. 1–11, 2019, doi:10.1063/1.5119840.

- B. Stürmer et al., “Agricultural biogas production: A regional comparison of technical parameters,” Renewable Energy, vol. 164, pp. 171–182, 2021, doi:10.1016/j.renene.2020.09.074.

- J. Maroušek et al., “Advances in the agrochemical utilization of fermentation residues reduce the cost of purpose-grown phytomass for biogas production,” Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, pp. 1–11, 2020, doi:10.1080/15567036.2020.1738597.

- B. K. McCabe, T. Schmidt, Integrated Biogas Systems: Local Applications of Anaerobic Digestion Towards Integrated Sustainable Solutions (Queensland, Australia: IEA Bioenergy, 2018).

- HomeBioGas, “What is Biogas? A Beginner’s Guide.” www.homebiogas.com/what-is-biogas-a-beginners-guide- . (accessed: 13-Aug-2021).

- G. Cayci, C. Temiz, S. S. Ok, “The effects of fresh and composted chicken manures on some soil characteristics,” Communications in Soil Science and Plant Analysis, vol. 00, no. 00, pp. 1–11, 2017, doi:10.1080/00103624.2017.1373794.

- K. A. Korys et al., “The review of biomass potential for agricultural biogas production in Poland,” Sustainability, vol. 11, no. 6515, pp. 1–13, 2019, doi:10.3390/su11226515.

- I. F. S. dos Santos et al., “Assessment of potential biogas production from multiple organic wastes in Brazil: Impact on energy generation, use, and emissions abatement,” Resources, Conservation & Recycling, vol. 131, pp. 54–63, 2018, doi:10.1016/j.resconrec.2017.12.012.

- Y. Y. Choong, K. W. Chou, I. Norli, “Strategies for improving biogas production of palm oil mill effluent (POME) anaerobic digestion: A critical review,” Renewable and Sustainable Energy Reviews, vol. 82, pp. 2993–3006, 2018, doi:10.1016/j.rser.2017.10.036.

- N. Izzah et al., “A review on life cycle assessment of biogas production: Challenges and future perspectives in Malaysia,” Biomass and Bioenergy, vol. 122, pp. 361–374, 2019, doi:10.1016/j.biombioe.2019.01.047.

- N. I. H. A. Aziz, M. M. Hanafiah, “Life cycle analysis of biogas production from anaerobic digestion of palm oil mill ef fl uent,” Renewable Energy, vol. 145, pp. 847–857, 2020, doi:10.1016/j.renene.2019.06.084.

- J. Piekutin et al., “The efficiency of the biogas plant operation depending on the substrate used,” Energies, vol. 14, no. 3157, pp. 1–12, 2021, doi:https://doi.org/10.3390/ en14113157.

- I. Yerima et al., “The influence of proximate composition of cow dung on the rate and volume of biogas generation in Maiduguri, North Eastern Nigeria,” International Journal of Environment, Agriculture and Biotechnology (IJEAB), vol. 4, no. 1, pp. 146–153, 2019, doi:http://dx.doi.org/10.22161/ijeab/4.1.24.

- A. Bulnes, “Anaerobic digestion and biogas plants in Africa: Integrated organic matter management for a sustainable agroindustrial sector.” 2017.

- U. Brémond et al., “Biological pretreatments of biomass for improving biogas production: An overview from lab scale to full-scale,” Renewable and Sustainable Energy Reviews, vol. 90, pp. 583–604, 2018, doi:10.1016/j.rser.2018.03.103.

- A. M. Wanjohi, E. K. Irungu, “An overview of consumption of biogas in the context of Somalia,” International Journal of Environmental and Health Sciences (JEHS), vol. 2, pp. 1–4, 2021.

- J. O. Egbere et al., “Generation of biogas from segregates of municipal solid wastes in Jos, Nigeria,” Global Journal of Pure and Applied Sciences, vol. 17, no. 1, pp. 41–45, 2011.

- K. A. Adeniran et al., “Relative effectiveness of biogas production using poultry wastes and cow dung,” Agricultural Engineering International: CIGR, vol. 16, no. 1, pp. 126–132, 2014.

- A. J. Eferi, A. P. Aderemi, “Potential, barriers and prospects of biogas production in North-Central Nigeria,” 3rd International Engineering Conference (IEC 2019), pp. 1–6, 2019.

- I. A. Rufai, “A review of the evolution and development of anaerobic digestion technology,” Journal of Engineering and Technology (JET), vol. 5, no. 1, pp. 100–111, 2010.

- A. Z. Abdul, A. M. Abubakar, “Potential swing to natural gas-powered electricity generation,” International Journal of Natural Sciences: Current and Future Research Trends (IJNSCFRT), vol. 10, no. 1, pp. 27–36, 2021.

- L. Ioannou-ttofa et al., “Life cycle assessment of household biogas production in Egypt: Influence of digester volume, biogas leakages, and digestate valorization as biofertilizer,” Journal of Cleaner Production, vol. 286, no. 125468, pp. 1–14, 2021, doi:10.1016/j.jclepro.2020.125468.

- M. Tanczuk et al., “Assessment of the energy potential of chicken manure in Poland,” Energies, vol. 12, no. 1244, pp. 1–18, 2019, doi:10.3390/en12071244.

- A. M. Wanjohi, E. K. Irungu, H. C. Gicheru, “Biogas program in Kenya: History, Challenges and Milestones,” International Journal of Environmental and Health Sciences (JEHS), vol. 2, pp. 1–3, 2022.

- P. K. Nimame, I. P. Nimame, R. A. Ekemube, “Importance of biogas utilization as alternative source in an energy deficit economy,” International Journal of Academic Information Systems Research (IJAISR), vol. 4, no. 12, pp. 17–21, 2020.

- R. Venkateshkumar, S. Shanmugam, A. R. Veerappan, “Anaerobic co-digestion of cow dung and cotton seed hull with different blend ratio: Experimental and kinetic study,” Biomass Conversion and Biorefinery, pp. 1–111, 2020, doi:https://doi.org/10.1007/s13399-020-01006-3.

- A. M. Abubakar, B. Iliyasu, Z. M. Sarkinbaka, “Detailed overview on POLYMATH software for chemical engineering analysis,” Journal of Engineering Research and Sciences (JENRS), vol. 1, no. 3, pp. 133–147, 2022, doi:https://doi.org/TBA.

- T. R. T. Yusof et al., “Evaluation of hydrogen and methane production from co-digestion of chicken manure and food waste,” Polish Journal of Environmental Studies, vol. 28, no. 4, pp. 1–11, 2019, doi:10.15244/pjoes/86222.