Design and Analysis of Flat Belt Conveyor for Segregation of Defective Products

Journal of Engineering Research and Sciences, Volume 1, Issue 4, Page # 62-67, 2022; DOI: 10.55708/js0104008

Keywords: Conveyor Belt, Design and FEA Analysis, Flat Belt, Segregation of Defective Product

(This article belongs to the Section Mechanical Engineering (MEE))

Export Citations

Cite

Patil, Y. , Patil, S. , Gawade, S. , Shinde, V. and Jawade, S. (2022). Design and Analysis of Flat Belt Conveyor for Segregation of Defective Products. Journal of Engineering Research and Sciences, 1(4), 62–67. https://doi.org/10.55708/js0104008

Yash Patil, Shivraj Patil, Suhas Gawade, Vaishnav Shinde and Samidha Jawade. "Design and Analysis of Flat Belt Conveyor for Segregation of Defective Products." Journal of Engineering Research and Sciences 1, no. 4 (April 2022): 62–67. https://doi.org/10.55708/js0104008

Y. Patil, S. Patil, S. Gawade, V. Shinde and S. Jawade, "Design and Analysis of Flat Belt Conveyor for Segregation of Defective Products," Journal of Engineering Research and Sciences, vol. 1, no. 4, pp. 62–67, Apr. 2022, doi: 10.55708/js0104008.

Belt conveyor system is mostly used in industries for transportation of raw materials and finished products. This paper includes study of detailed design procedure and analysis of flat belt conveyor components for light duty applications. Belt conveyors used for segregation of defective products up to 2 kg maximum load whose conveyor capacity is 2 TPH and speed of the conveyor will be 3.5 m/min. Our paper includes study of design calculation of conveyor and FEA analysis of pulley, shaft and conveyor belt. 3D model is created using solid work software. FEA is done on ANSYS and Inventor software with appropriate loading condition, considering calculated tension. Stress analysis of shaft, pulley and belt is done to find highest stressed area of belt conveyor. By following the design procedure for flat belt conveyor system, all geometrical parameters obtained are within limits and design of conveyor is safe. In FEA, contact status and contact pressure between belt and pulleys are properly sticky and in contact. Max stress acting on belt is 58.85 MPa and deformation will occur at 87.88 MPa. Stress on shaft comes out to be 13.17 MPa.

1. Introduction

Belt conveyor is commonly used equipment in industries for continues transportation of materials [1]. Belt conveyors are categorized in two industrial categories. First category for material handlings like for carrying boxes in the factories and bulky materials handling like used for transportation of industrial or of agriculture materials, like grains, coals, and ores, generally in outdoor location. Belt conveyors are more reliable, provide high stability and more conveyor capacity, have less maintenance [2].

Conveyor belt systems are classified according to their operational mechanisms such are rollers, chains, screw, spiral, vibrating, and pneumatics [3]. Selection of conveyor systems are based on functioning requirement, sizes, shapes or weights of materials, travelling distances, speed requirement, atmospheric conditions and economical.

Conveyor belt consist of two or more pulleys, with continuous loop of materials, around which conveyor belt rotate. One or both the pulleys are powered, to provide motion to belt and carryout the material on the belt from one to another end. The powered pulleys are called drive pulleys while unpowered pulleys are called idlers. Rollers are used in between both pulleys to support belt and to improve efficiency and maintain speed and minimize belt sag. [4]

Belts are made up from one or many layers of materials may be from rubbers. Belt used for materials handling has 2 layers. Inner layer of materials provides linearly strengths or shapes known as carcass and above layers known as cover. A carcass is mostly of cottons or the plastics web or meshes. Covers are of different rubbers and plastics compound specified by use of belt [4].

Cover may be made up from more exotic material for unusual application like silicones for heating or gum rubber when tractions are essential. [4] Conveyor technologies are also useful for conveyor transportation like movable sidewalks and lifts, also in manufacturing assembly line.

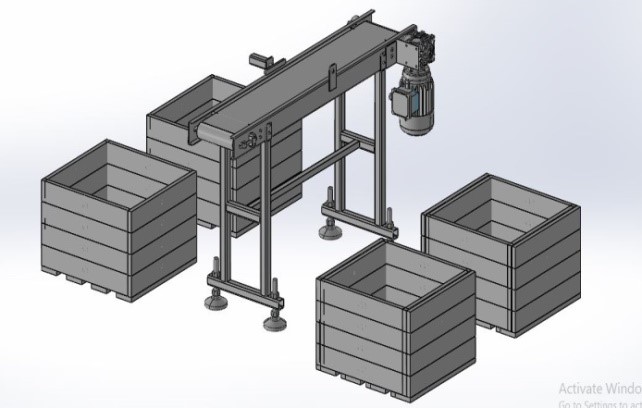

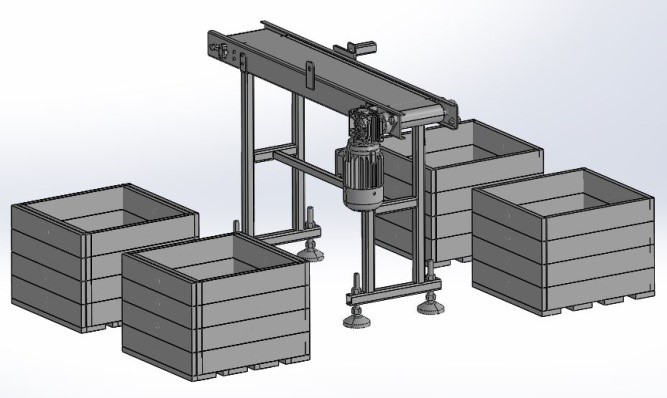

This paper studies about design and analysis of a flat belt conveyor system for separation of defective products from conveyor line in industries where products are manufactured in bulk. During inspection of final products lot of man power is required and is more time consuming. Sometimes due to human error damaged products are added in selected lot, which directly affects reputational and economical losses of firms. Therefore, to avoid this problem, we have designed and analyzed a conveyor system which automatically segregates defective products, using pneumatic actuators and sensors, according to their geometrical parameters and minimizes inspection time and cost associated during process with no human touch required using python interfacing. 3D model is designed as per analytical values obtained using solid works software. FEA analysis is also made of pulley, shaft and conveyor belt.

2. Problem Statement:

Metal materials like steels, aluminum, copper plate or strip, are mostly used in automobile’s manufacturing, bridges construction, aerospace fields or other pillar industries. But during actual industrial production processes, processing tools gets damaged due to harsh industrial environment, which leads to certain quality problems to metal material product. Few product surfaces show defects in large-area or the periodic characteristic not only impact on subsequent production but also threatens the quality of terminal product, which causes economical or reputational losses to manufacturing industries. [5] So we have designed conveyor mechanism on the detection of defective product and segregation with the help of sensors, pneumatic actuators and python program interfacing.

3. Material and Methods

The defective product sorting machine consists of flat belt conveyor mechanism. Pneumatic cylinder and proximity sensors are used for detection and sorting of defective product. Flange mounted motor with gear box is connected at head pulley shaft. Complete sorting unit is operated using python interfacing.

Material to be sorted can be fed with the help of hopper or manually. Both the head and tail end pulleys are kept of same diameter and same as shaft. Rubber belt carries out the material till the sensor senses the products, and if the product is sensed to be defective product then DAC pneumatic actuator operates and product get sorted from queue. Conveyor system is designed, for maximum load up to 2 kg.

4. Design of Conveyor:

Design flat belt conveyor system for sorting of defective products having conveyor capacity of 2 tones/hr. and maximum weight to be carried is up to 2kg. Center distance between both pulleys is 1000mm and height of conveyor is 518 mm. Other specifications:

- Material density: 1.5 tones/m³

- Inclination angle: 0°

- Angle of repose: 45°

- Lump size: 120mm

- Conveyor speed: 3.5 m/min

4.1. Belt Speed and Width Calculations:

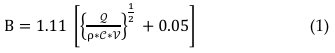

Determine the width of conveyor speed using the relation,

B= 2*Amax+ 200 …for solid material

B= Amax+ 200 …for fine material

Where, Amax denotes lump size

For solid material, the belt width comes out to be 440mm.Selecting the standard belt width of 400 mm from PSG design data book [6].

Now, check for the belt speed,

where, B = Belt Width

Q = Conveyor Capacity = 2 tones/m³

![]() = Density of Material =1.5 tones/m³

= Density of Material =1.5 tones/m³

C = Surface Factor for Type of Idler

C = 240 (For flat belt)

V= Belt Speed (m/sec)

So, the value of belt speed is 0.0576 m/sec i.e. around 3.5m/min which is less than 1.5 m/sec, the allowable speed for 400 mm width belt. Therefore the belt width of 400 mm is acceptable. The obtained values are compared with design data given in PSG design data book.[6]

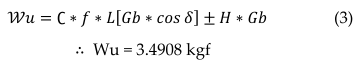

4.2. Resistances of belt at top and bottom run

Resistance of belt at top run [𝒲ο ]:

![]()

Where, C= secondary resistance factor

C= 9 (for conveyor length ≤ 3 m)

f = 0.02 (for standard conveyors)

L= length=1000m

Gg=weight of conveyed material per meter length, kgf/m= 9.65 kg/m

Gb =weight of belt per meter length kgf/m = 5 kgf/m

𝛿 = inclination angle = 0°

H= height of conveyor = 518.16 mm

![]()

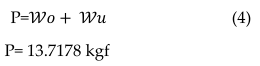

Resistance of Belt at Bottom Run [Wu]:

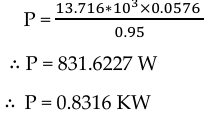

Power (P) can be determined as;

Power = Resistance of Belt at Top Run + Resistance of Belt at Bottom Run

4.3. Belt Tension Calculations

Effective force on belt is given by;

![]()

Also,

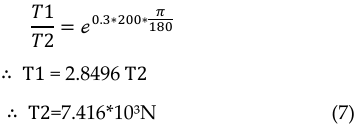

![]()

Where, 𝜇 = coefficient of friction between belt and pulley 𝜇 = 0.3

𝜃 = angle of lap

Considering angle of lap over load pulley as 200° ˃ 165° to avoid slip of belt during running conditions

Putting in equation 5,

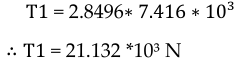

Maximum belt tension on carrying side is 21.132*10³ N and minimum slack side tension is 7.416*10³ N.

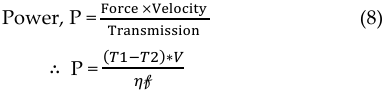

4.4. Selection of Driving Unit

Where, ![]() = transmission efficiency

= transmission efficiency

![]() = considering efficiency as 95%

= considering efficiency as 95%

Therefore, from PSG design data book a Flange Mounted Motor of 1.1 kW ratings and 1000RPM is selected. [6] The motor will be connected to the gear box to reduce and maintain the rpm of driving pulley shaft.

4.5. Conveyor Pulley

As the conveyor is flat belt conveyor system both the pulleys are of same diameter having same length and material as well. [6]

For the belt width selected of 400 mm, from PSG design data book selected the standard diameter of conveyor pulley drum, D, to be 110mm and have standard face width of 450 mm and edge clearance of about 25 mm is considered on both ends of pulley.[7]

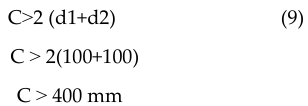

4.6. Belt length and thickness

Center distance between pulleys is 1000mm checking for the minimum center distance required for conveyor using the relation,

Therefore center distance greater than 400 mm will be accepted as per requirement. Therefore taking center distance between pulleys as 1000 mm as given.

For open belt drive system length of shaft can be determined as;

![]()

where, C is center distance

Dl = diameter of large pulley and

Ds = diameter of small pulley

![]()

But taking into considerations, initial tension, the belt length should be shortened by 1%

L = 2291.018 ≅ 2290 mm

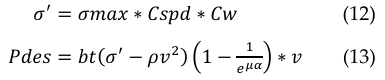

For rubber belt coefficient of frictions is taken as 𝜇 = 0.4

Design power(Pdes)=service factor*required power (11)

Design power (Pdes) = 0.997 KW

Design stress for rubber belt material can be taken as 1.5 MPa & Density of rubber belt is 1140kg/m³.

Design stress in belt can be calculated as,

where α= angle of lap=200°

α= 3.49 rad

bt =11509.80 mm²

So, selecting standard Rubber Belt as;

Length of belt =2290 mm

Width of belt = 450 mm

Thickness of belt = 3 mm

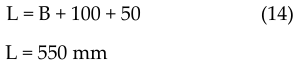

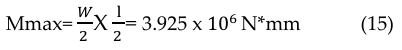

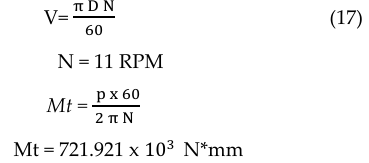

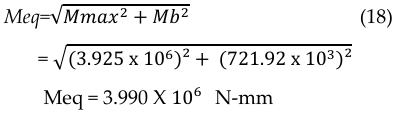

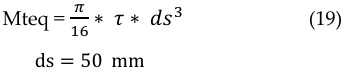

4.7. Pulley Shaft Calculations:

Length of shaft considering the belt width of 400 mm and clearance of 50 mm and width of bearings on both ends of shaft, [8]

Max bending force on pulley,

Twisting moment on shaft,

To find N, Velocity of belt (V),

Equivalent torque on shaft;

Selecting the carbon steel material of grade C45 from PSG design data book having properties,

σy=360 N/mm2

FOS = 4

(𝜏) = 45 N/mm2

Considering torsional failure of shaft;

Selecting standard shaft of 50 mm diameter and 550 mm length of C45 grade material for both pulleys from PSG design data book.

4.8. Selection of Bearing:

Bearings are machine elements which supports other moving machines elements. [8] Bearings permit the relative motion between the contact surfaces of the members, while carrying the load. [9] Deep Groove Ball Bearings are selected for both the pulley shafts having

d = Internal diameter = 50 mm

D = Outer diameter = 80 mm and

w = width of bearing = 16 mm

5. FEA for Conveyor Belt, Pulley and Shaft:

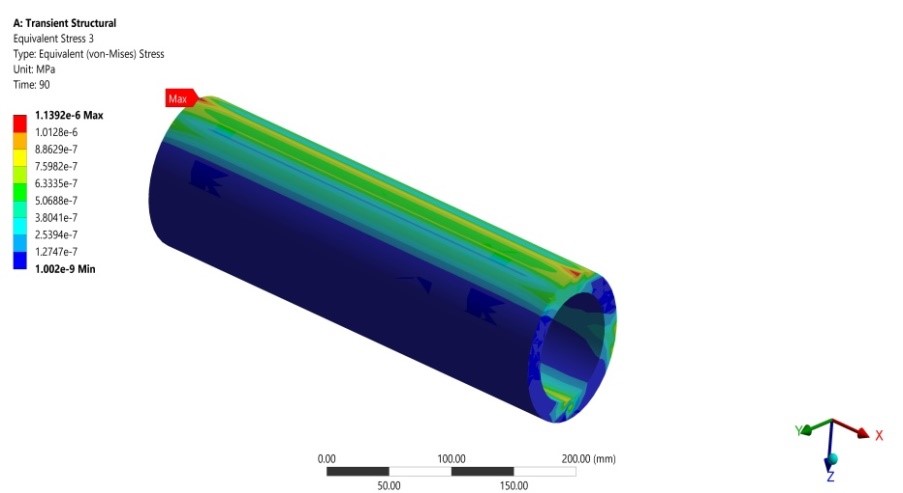

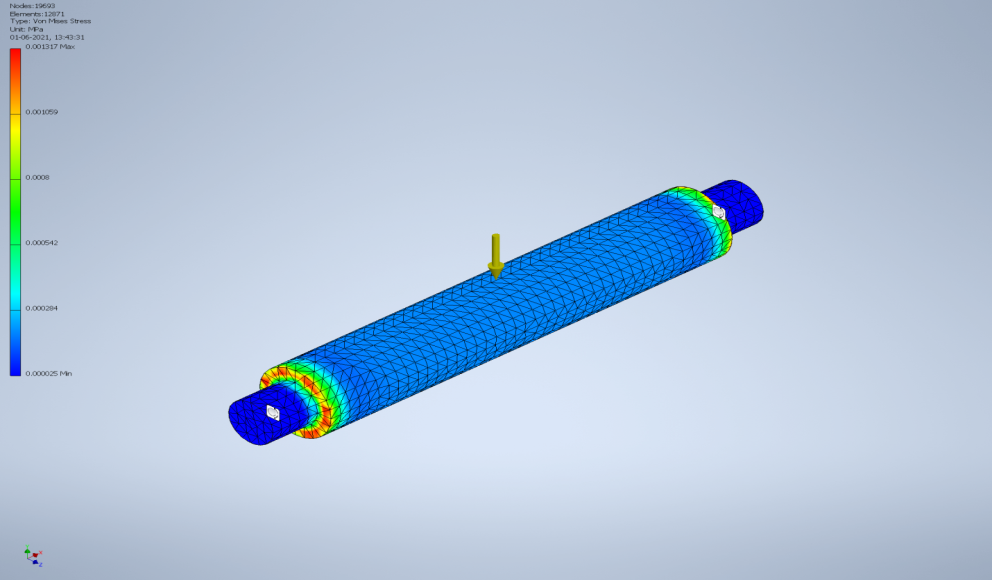

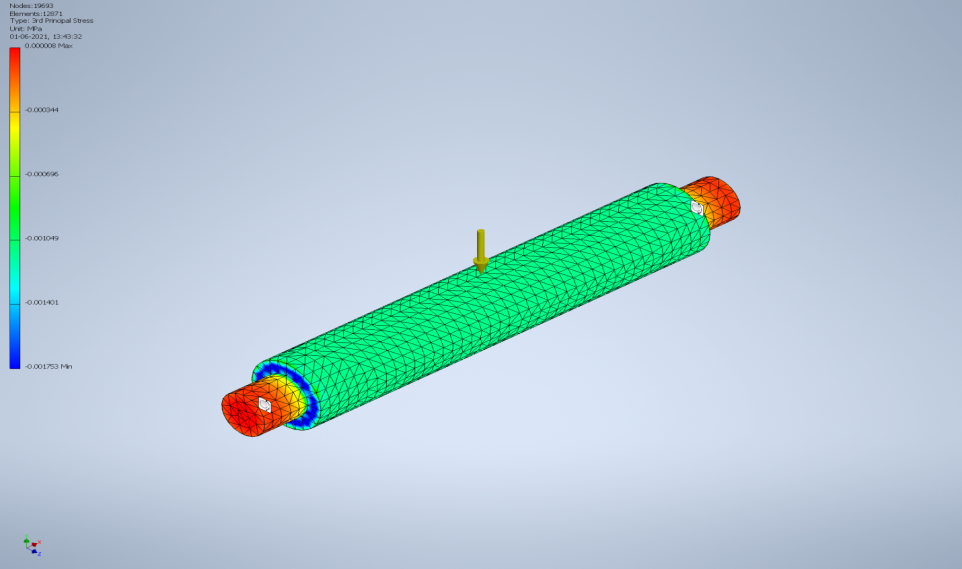

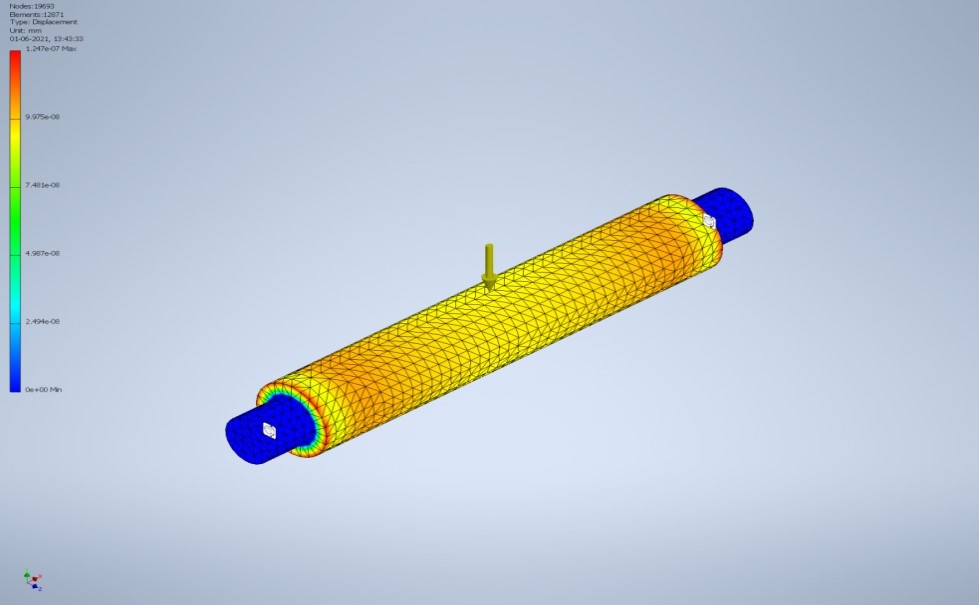

Analytical design executed successfully using ANSYS workbench and inventor softwares. By applying accurate force and constraint are simulated in ANSYS and inventor to achieve precise result. FEA is performed to find maximum and minimum von mises stress on belt pulleys and shaft, contact status and maximum contact pressure between belt and pulley and stress on shaft at bearing end.

For FEA all the standard material’s properties are considered. Dead weights for both pulleys are considered. Resultant tensions are obtained and applied as uniform radial pressures on a pulley surfaces in area of angle of wrap, and over belt width as well. Torque obtained for driven pulley is applied on drive end of shaft. Initial 3D simulation model of pulley system is designed using solidworks and catia softwares.

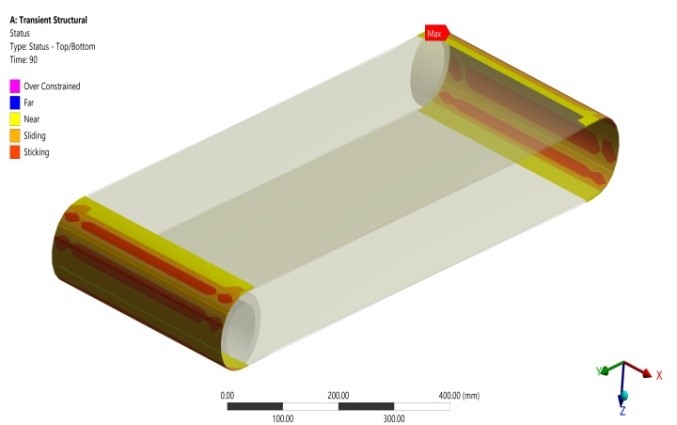

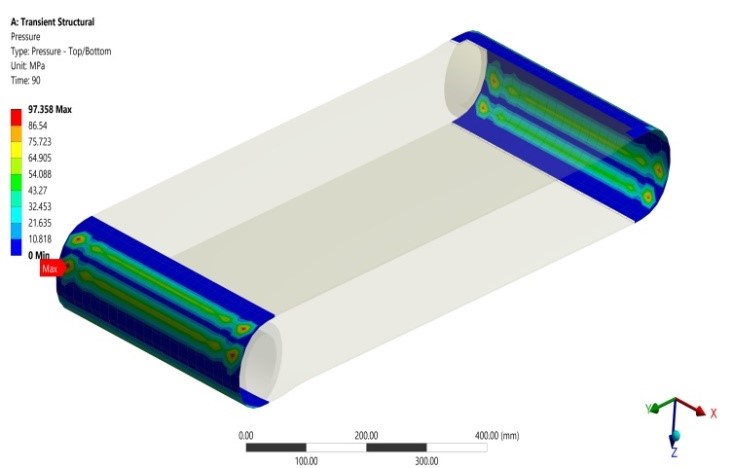

The contact status between belt and pulley shows the belt is properly in contact and sticked with pulley and the maximum contact pressure between belt and pulley is 97.35 MPa.

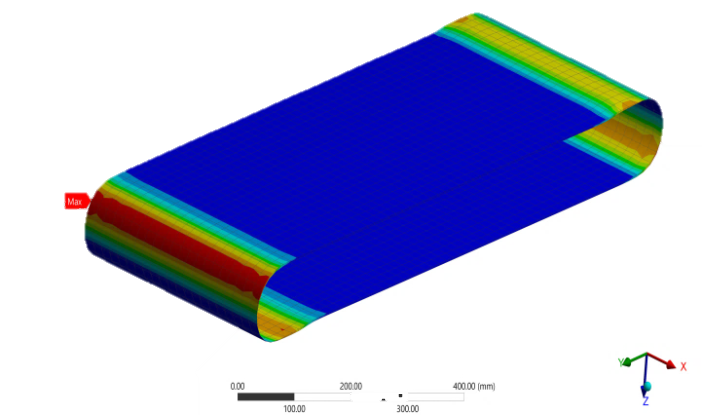

The tensions acting on the belt calculated by analytical methods on carrying side and slack side are 21.132*10³ N and 7.416*10³ N. The maximum stresses on belt are analyzed using ansys software.

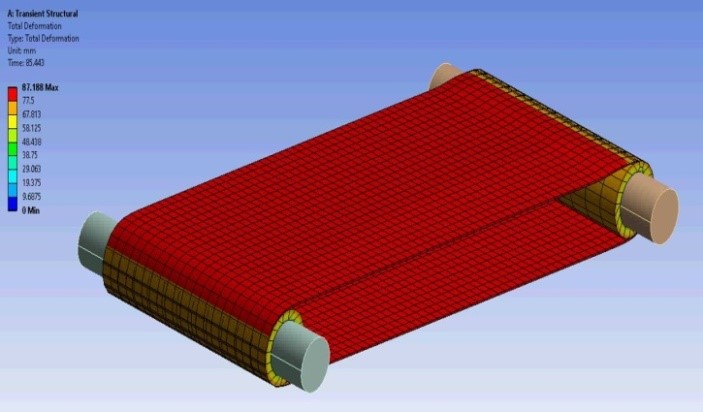

Maximum von mises stresses in shaft is 58.85 MPa. Deformation of belt at worst conditions, occurs at 87.88 MPa

Maximum stresses on shaft due to pulley are 12.47 MPa. The analysis is done for belt, pulley and shaft for carrying side is within range and hence design is safe. Similarly, the analysis is done for tail side arrangement.

6. Conclusion

This paper is based on theoretical calculations, designing and FEA of flat belt conveyor systems for sorting of defective products. The main purpose to design the system is to minimize inspection time of product on conveyor line and to minimize the manpower required for inspection and sorting. The system is operated through python interfacing and the design is easily understandable.

Through our design the defective products are inspected and get sorted, if found defective, without any human touch. Components of the conveyor system are analyzed using Ansys and inventor software. The results achieved are within acceptable range and design is safe. Hence, the conveyor system is designed successfully.

7. Future Scope

Our defective product sorting system inspects and segregates defective products without any human touch. But it has limitations to segregate products in multiple sections. In future using latest technology and resources the design and components can be modified as per requirements to main minimize inspection time and manpower. Also, this kind of systems can also be designed for various types of raw materials for heavy duty applications.

Acknowledgement

Our guide Prof. Mrs. Samidha Jawade, Assistant Professor, Department of School Of Mechanical Engineering- MIT World Peace University, Pune. She has encouraged and motivated us throughout this project, and helped in every step of project development.

8. Conflicts of Interest

The authors declare no conflict of interest.

- P. K. V. Konakalla Naga Sri Ananth, Vaitla Rakesh, “Design and Selecting the Proper Conveyor-Belt,” International Journal of Advanced Engineering Technology E, vol. IV, no. II, pp. 43–49, 2013.

- L. Zhao, Y. Lin, “Typical failure analysis and processing of belt conveyor,” Procedia Engineering, vol. 26, pp. 942–946, 2011, doi:https://doi.org/10.1016/j.proeng.2011.11.2260.

- M. R. Sayali Todkar, “Design of Belt Conveyor System,” International Journal of Science, Engineering and Technology Research, vol. 7, no. 7, pp. 458–462, 2018.

- Z. B. R. gunasegaran Madasamy, “Automated Mechanical SOrting Device for Mixed Household Wastes,” LAP Lambert Academic Publishing, no. February 2013, pp. 50, 2013.

- P. Elamurugan et al., “Automatic material segregation using PLC,” International Journal of Engineering and Technology(UAE), vol. 7, no. 2, pp. 376–380, 2018, doi:https://doi.org/10.14419/ijet.v7i2.24.12088.

- PSG college of engineering, 307Design_Data_Data_Book_Of_Engineers_By_PSG (Coimbatore, India: Kalaikathir Achchagam).

- K. S.J. Ojolo, J.I. Orisaleye, Adelaja, A.O., “Design and Development of Waste Sorting Machine,” Journal of Emerging Trends in Engineering and Applied Sciences (JETEAS), vol. 2, no. 4, pp. 576–580, 2011.

- Bhandari V. B., Design of Machine Elements – V. B. Bhandari – Google Books (1994).

- P. K. Shanjenbam Brojendro Singh, Abu Salah Muslaha Uddin Laskar, Biltu Roy, Aminul Hoque Choudhury, Zahidul Islam, Jakir Hussain Mollah, Shadeed Masood Ul Hoque, Mohsin Ali, “Design of Municipal Dry Waste Segregating Machine Using Conveyor,” International Journal of Innovative Research in Science, Engineering and Technology (An ISO, vol. 5, no. 5, pp. 7156–7162, 2016.

No related articles were found.