Enhancing the Contribution of Recycled Asphalt Shingles to Asphalt Binders Using Rejuvenators

Journal of Engineering Research and Sciences, Volume 1, Issue 11, Page # 16-33, 2022; DOI: 10.55708/js0111003

Keywords: Recycled Asphalt Shingles, Rejuvenators, Pyrolysis Oil, Milling

(This article belongs to the Section Civil Engineering (CVE))

Export Citations

Cite

Deef-Allah, E. and Abdelrahman, M. (2022). Enhancing the Contribution of Recycled Asphalt Shingles to Asphalt Binders Using Rejuvenators. Journal of Engineering Research and Sciences, 1(11), 16–33. https://doi.org/10.55708/js0111003

Eslam Deef-Allah and Magdy Abdelrahman. "Enhancing the Contribution of Recycled Asphalt Shingles to Asphalt Binders Using Rejuvenators." Journal of Engineering Research and Sciences 1, no. 11 (November 2022): 16–33. https://doi.org/10.55708/js0111003

E. Deef-Allah and M. Abdelrahman, "Enhancing the Contribution of Recycled Asphalt Shingles to Asphalt Binders Using Rejuvenators," Journal of Engineering Research and Sciences, vol. 1, no. 11, pp. 16–33, Nov. 2022, doi: 10.55708/js0111003.

Recycled asphalt shingles (RAS) have been a valuable recycled component in asphalt mixes for decades. However, research into how the aged and oxidized air-blown RAS binder interacts with the neat asphalt binders in asphalt mixtures is underway. Furthermore, due to the stiffness of RAS binders, RAS-containing asphalt mixtures are prone to significant cracking, particularly at low temperatures. As a result, an innovative technique was developed and used in this study to increase the contribution of RAS particles in the asphalt binder. This technique was primarily dependent on interacting RAS particles with rejuvenators before mixing them with the asphalt binder. Moreover, this technique allowed the oxidized and aged binders in the RAS to absorb aromatics to compensate for the lost low-molecular-weight fractions during the air-blowing process and alter their aged behavior. Five rejuvenators were utilized, including four pyrolysis oils (B2A, P4, P8, and P4D) and one recycling agent (Evoflex). One source of post-consumer RAS was collected, milled, and sieved into two sizes. The rejuvenator was chosen to weigh 45% of the RAS, except for the P4D, which contained a double amount of P4 oil and weighed 90% of the RAS. RAS or the RAS that interacted with oils, was mixed with one source of asphalt binder with a performance grade of 76−16. The RAS with rejuvenator samples weighing 7.5% and 15% of the asphalt binder interacted with the neat binder. The addition of P4D or Evoflex to RAS reduced the stiffness and elasticity of the modified asphalt binders due to the RAS particles' absorption of aromatics in oils. This trend improved the modified binders' fatigue and thermal cracking resistance. Milled RAS particles of a smaller size (50-100) reacted with oils more than RAS particles of a bigger size (30-50), which caused stiffer properties for the binders modified with the smaller RAS particle size.

1. Introduction

The usage of recycled asphalt shingles (RAS) in the pavement industry is growing due to the valuable constituents that make them more suitable for use with asphaltic mixes [1]. RAS contains oxidized air-blown asphalt binders, polymers, granules, mineral fillers, and fibers [2–4]. Utilizing RAS in asphalt mixes modifies the performance of the total binders in these mixes due to interactions between RAS and the virgin binders [4–6]. In asphalt mixtures, two types of shingles are permitted: Manufactured waste and tear-off (post-consumer) shingles [7, 8]. Manufactured waste shingles are waste products of the shingle manufacturing process, whereas post-consumer shingles are shingles that primarily originate from residential and commercial building roofs after their useful lives have ended [9]. When compared to the binders incorporated in the manufactured waste shingles, the oxidation impact on the post-consumer shingles created stiffer characteristics for their asphalt binders [10, 11].

The use of RAS in asphalt mixes minimizes the demand for natural resources, emissions during the manufacturing process, and the amount of material discarded in landfills [12, 13]. The asphalt binders in RAS are more difficult to interact with virgin asphalt binder in asphalt mixes than asphalt binders in reclaimed asphalt pavement (RAP) [5, 14–16]. Because the oxidized and aged binders in RAS enhanced the stiffness and elasticities of the binder, utilizing RAS in asphalt mixes increased the rutting resistance of the mixes and extracted asphalt binders as compared to virgin mixes and binders [4, 5]. However, increasing the stiffness of the asphalt binder lessened its ductility, and relaxation potential, and increased its cracking capability [6, 17, 18].

The wet process of adding RAS to asphalt binders boosted fatigue cracking resistance, resulting in higher fatigue life values. However, the Superpave fatigue parameter (G*.sinδ) values increased, suggesting decreased fatigue cracking resistance [19]. Another study revealed that using the RAS binder with a neat binder did not influence G*.sinδ values when compared to the neat binder value [20]. Using RAS in asphalt mixes enhanced the fatigue cracking resistance of the extracted binders when compared to extracted binders from mixtures containing binders with the same performance grade (PG) but lower RAP percentages [21, 22]. This was due to the polymeric components included in shingles [5] that enhance the fatigue cracking resistance. Using RAS as a modifier with the neat binder influences the low-temperature performance of the modified asphalt binder [6,23]. When the RAS binder was blended with neat binder, the low temperature increased by 0.4°C for every 1% of asphalt binder replaced by RAS [23]. When compared to binders extracted from RAP-containing mixes, the use of RAS exacerbated the low-temperature characteristics of extracted binders [6].

Using rejuvenators balances the performance of the modified asphalt binders by marginally decreasing the binders’ stiffness at high temperatures and increasing their fluidity at intermediate and low temperatures [24–26]. They vary from organic oils (such as vegetable oil and tall oil) to petroleum-based rejuvenators (such as used motor oil and aromatic extracts) [27]. Evoflex as a rejuvenator or recycling agent enhanced the contribution of the aged binders in recycled components in asphalt mixes by enhancing the mobility of these aged binders [5, 14]. Because pyrolysis oil has a high concentration of aromatics [28, 29], it was used as a rejuvenating agent, allowing the aged binders to achieve characteristics equivalent to the unaged asphalt binder [30]. Pyrolysis oil is produced by the thermal decomposition of tires in an oxygen-deficient environment, which also produces fumes and solid residue [31]. It was assumed that it would interact with RAS to adjust its aged binder with low-molecular-weight fractions before being introduced to the asphalt binder.

An innovative methodology was adopted in this study to enhance the role of RAS in asphalt binders. First and foremost, RAS particles were milled to improve their compatibility with the rejuvenators before being introduced to the asphalt binder. Then, the milled RAS particles were interacted with rejuvenators and preheated in the oven before mixing with asphalt binders to alleviate the issues associated with employing RAS in asphalt mixes at low temperatures. This technique enables the oxidized and aged binders in RAS to absorb aromatics to compensate for the lost low-molecular-weight fractions during the air-blowing process and adjust their aged behavior. The key to this novel approach was the creation of a homogenous modified asphalt binder blend with superior performance at high, intermediate, and low temperatures.

2. Materials and Methods

2.1. Materials

One source of asphalt binder was used with a PG of 76−16, and one source of post-consumer RAS was selected. The RAS particles were cleaned from the wood and plastic pieces, then they were milled using a vibratory disc mill. The particles of RAS were milled to enhance their compatibility with the rejuvenators and asphalt binder using the wet process. The milled particles were sieved on #30, #50, #100, #200, and a pan. Two particle sizes of RAS were utilized: The first size was 30-50 and the second size was 50-100. The first particle size represents particles passed from #30 and retained on #50, and the second particle size simulates particles passed from #50 and retained on #100. Different types of rejuvenators were used, which represented pyrolysis oils (B2A, P4, P8, and P4D) and a recycling agent (Evoflex). These rejuvenators were introduced to the RAS to decrease the stiffness of the binder in the RAS by absorbing aromatics from the rejuvenators, and then the blend of RAS plus rejuvenator was mixed with the neat asphalt binder. More details about the used rejuvenators are introduced in Table 1.

Table 1: Details of Rejuvenators

Rejuvenator Code | Details of the As-Received Rejuvenators |

B2A | Tire oil was collected from trays 3 and 4 and post-cooked at 510° to 868°F |

P4 | Tire oil was collected from combined trays and post-cooked at 570°F for 4 hrs |

P8 | Tire oil was collected from combined trays and post-cooked at 570°F for 8 hrs |

P4D | Double the percentage of P4 oil |

E | Evoflex CA-9 |

2.2. RAS, Asphalt Binder, and Rejuvenators Interactions

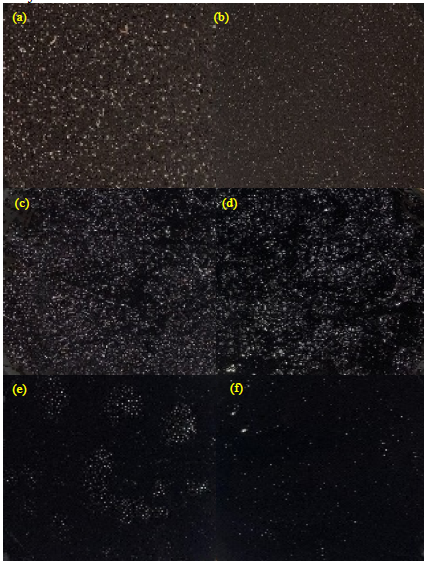

Milled RAS with two particle sizes (Figures 1-a and 1-b) has interacted with the different types of rejuvenators as indicated in Figures 1-c and 1-d. The weight of the rejuvenator was selected to be 45% by the weight of the RAS except for the P4D—a double percentage of P4 oil—the weight of the P4 oil was 90% by the weight of the RAS. After stirring the rejuvenator with RAS manually, the interacted RAS with rejuvenator samples were transferred to the oven at 90°C and kept there for 6 hrs to enhance the absorbance of RAS to aromatics. Finally, the RAS with rejuvenator samples (Figures 1-e and 1-f)—with a weight of 7.5% and 15% by the weight of the asphalt binder—interacted with the PG 76−16 asphalt binder using a high shear mixer at 190°C interaction temperature, 1800-rpm interaction speed, and 4-hrs interaction time. Modified binder samples were collected at 0.5-, 1-, 2-, and 4-hrs interaction times during the interaction process for further analyses.

2.3. Methods

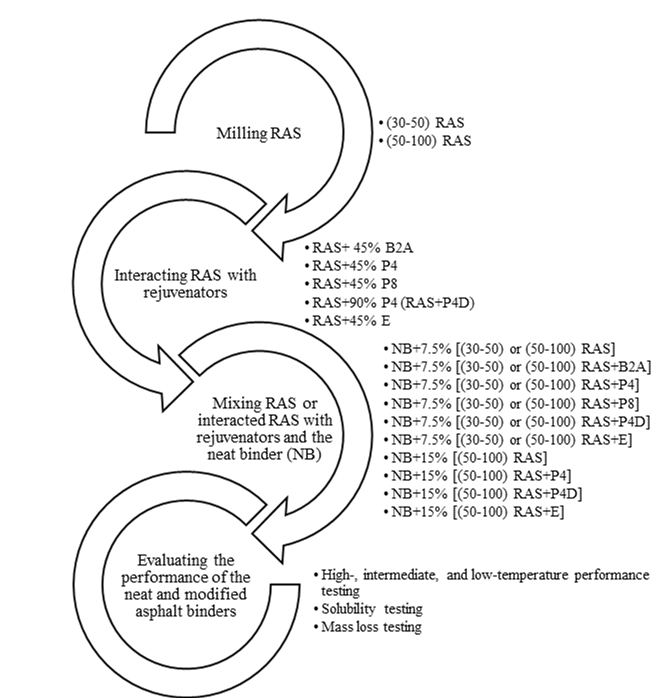

The steps followed to achieve the experimental design of this study are depicted in Figure 2. Four major steps were followed. The RAS particles were milled in the first step. The second step aimed to interact rejuvenators with RAS particles. In the third step, RAS and interacted RAS with the rejuvenators were mixed with the neat binder. The fourth step included the characterization of the neat and modified asphalt binders. The following subsections explain the full experimental testing that was conducted in detail.

2.3.1. Short-Term Aging for Asphalt Binders

Short-term aging was carried out using the rolling thin film oven (RTFO) device according to ASTM D2872-19 [32] for neat and modified asphalt binders. The mass loss percentage was calculated for the neat and modified asphalt binders after the RTFO test.

2.3.2. Long-Term Aging for Asphalt Binders

Long-term aging was carried out according to ASTM D6521-19a [33] using a pressure aging vessel (PAV) for the neat and modified asphalt binders.

2.3.3. High- and Intermediate-Temperature Rheological Properties of Asphalt Binders

A Dynamic Shear Rheometer (DSR) was used following ASTM D7175-15 [34] to characterize the neat and modified asphalt binders’ high- and intermediate-temperature properties. Specimens with a thickness of 1 mm and 25 mm diameter for the original and RTFO-aged binders were tested. Additionally, 2 mm-thick and 8 mm-diameter specimens were used for PAV binders.

The temperature sweep test was implemented for the original, RTFO-aged, and PAV-aged asphalt binders at different temperatures. For the original and RTFO-aged binders, 70°C, 76°C, and 82°C temperatures were selected. For the PAV-aged binders, 28°C, 31°C, and 34°C temperatures were selected. For the frequency sweep testing, conducted on the original binders, three temperatures were selected (70°C, 76°C, and 82°C) through different frequencies (50 rad/s to 0.5 rad/s). The master curves were analyzed, using the frequency sweep test results, at 76°C as a reference temperature.

A multiple stress creep recovery (MSCR) test was conducted following ASTM D7405-20 [35] to evaluate the resistance of RTFO binders to rutting distress. This was achieved by calculating the percentage of recovery (%R) and non-recoverable creep compliance (Jnr) at 76°C by applying ten creep cycles at two different levels of stress (0.1 kPa and 3.2 kPa). For each creep cycle, the loading time was 1 sec, and the unloading time (recovery) was 9 sec. The %R reflected the binders’ elasticities, and the Jnr indicated the binders’ stiffnesses.

2.3.4. Low-Temperature Rheological Properties of Asphalt Binders

Low-temperature properties of neat and modified asphalt binders were evaluated according to ASTM D6648-08 [36] using a bending beam rheometer (BBR).

2.3.5. Insoluble Percentages of Asphalt Binders

Because of the use of RAS in the modified asphalt binders, the solubility of the asphalt binders in toluene was evaluated following ASTM D2042-22 [37].

3. Results and Discussion

3.1. Mass Loss Results

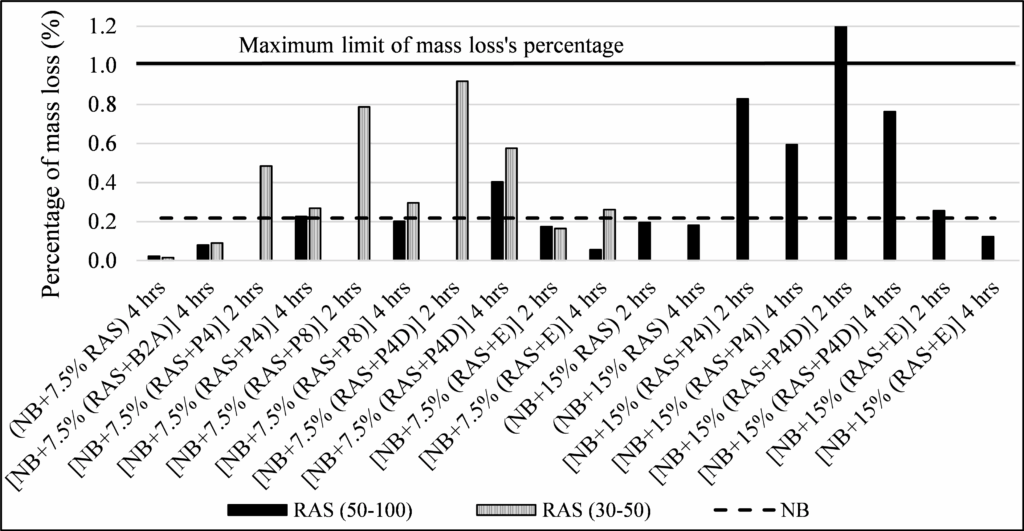

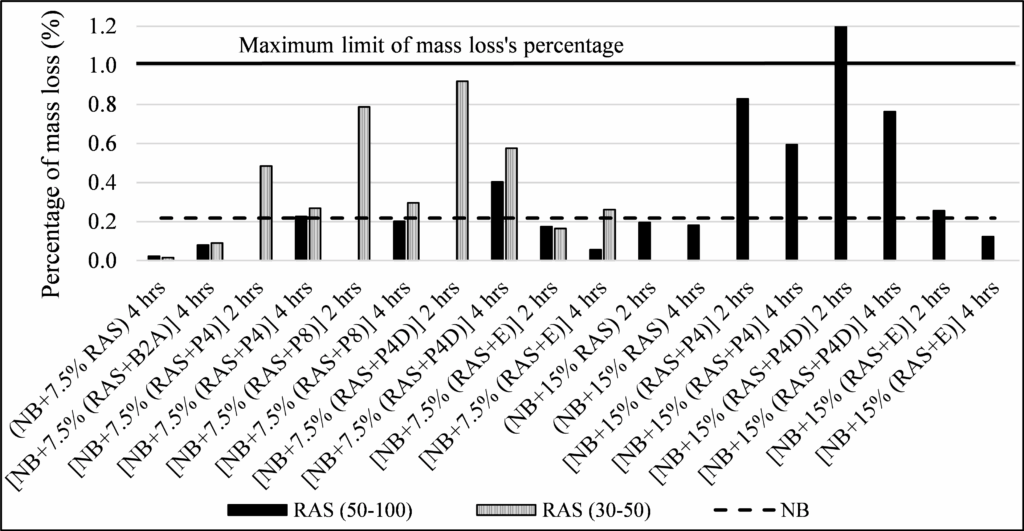

The mass losses after the RTFO test were calculated and depicted in Figure 3 for the neat and modified asphalt binders at 2- and 4-hrs interaction times. The percentages of mass losses were under the maximum threshold (1%) except for the binder modified by 15% RAS plus P4D and interacted at 2 hrs. The use of RAS with the neat binder decreased the percentage of mass loss when compared to the percentage of the neat binder. The lowest percentage of mass loss was recorded for the neat binder modified by 7.5% RAS. For asphalt binders modified by RAS and rejuvenators, the percentages of mass losses increased due to the existence of low-molecular-weight fractions (aromatics) in the rejuvenators that were lost after the RTFO process. Furthermore, increasing the interaction time from 2 hrs to 4 hrs decreased the percentage of mass losses due to the evaporation of the aromatics during the interaction processes. The mass loss percentages for the modified binders with RAS (30-50) were higher than those of the modified binders with RAS (50-100). This occurred because the particles of RAS with a size of 50-100 absorbed more oil and had more compatibility with the binder than the particles of RAS with a size of 30-50. For the 50-100 RAS, increasing the percentage of the interacted RAS with oils from 7.5% to 15% by the weight of the neat binder caused an increase in the mass loss percentages. This happened due to the higher amount of aromatics that were lost from the binders modified with higher percentages of the interacted RAS with oils.

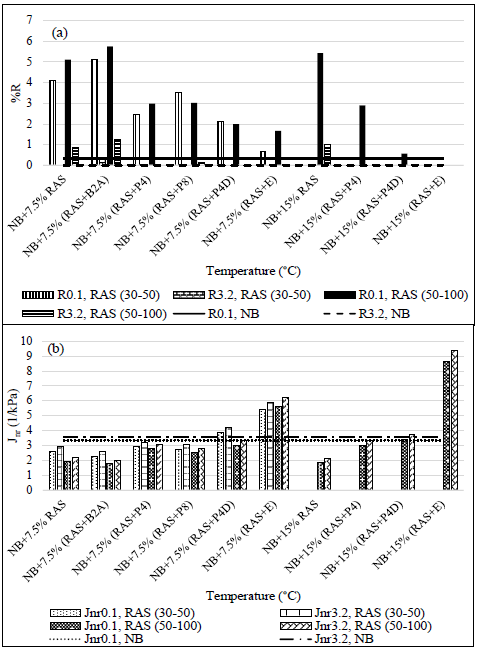

3.2. High-Temperature Rheological Results

The MSCR test results (%R and Jnr) are presented in Figure 4 for the RTFO neat and modified asphalt binders interacted at 4 hrs. The %R results at 0.1 and 3.2 kPa stress levels and 76°C are depicted in Figure 4-a, and the Jnr results at 0.1 and 3.2 kPa stress levels and 76°C are introduced in Figure 4-b. The general trend was that the %R values for the modified binders were higher than that of the neat binder due to the existence of the oxidized air-blown RAS binder that increased the elasticity (%R). The highest %R values were noted for the neat binder modified by RAS+B2A, and the lowest %R values were for the neat binder modified by RAS+E. The stiffness values of the modified binders were higher than for the neat binder by showing lower Jnr values except for samples modified by RAS (30-50) and P4D oil and for the samples modified by RAS+E. The lowest Jnr values were noted for the neat binder modified by RAS+B2A, and the highest Jnr values were for the neat binder modified by RAS+E.

When comparing binders modified by the RAS+P4 and the RAS+P8, the binders modified by the RAS+P4 had lower stiffness and elasticity values than those of the binders modified by the RAS+P8. Furthermore, the binders modified by the RAS+P4D oil had lower stiffness and elasticity values than those of the modified binders by RAS+P4.

When comparing the RAS particles of two sizes, the general trend was that the RAS particles with the smaller size showed higher elasticities (higher %R values) and higher stiffnesses (lower Jnr values). More compatibility happened between the RAS particles with a smaller size and the asphalt binder than between particles with a larger size and the same binder. These results confirmed that binders modified by RAS and B2A oil had the highest stiffnesses and elasticities, while binders modified by RAS and E oil showed the lowest stiffnesses and elasticities. Increasing the percentage of RAS from 7.5% to 15% by the weight of the neat binder showed an increase in stiffness and elasticity due to the oxidized air-blown binder in the RAS. However, increasing the percentage of the interacted RAS with oils from 7.5% to 15 % by the weight of the neat binder depicted a decrease in elasticity and stiffness. This reflected that interacting RAS with rejuvenators decreases the stiffness of the oxidized air-blown binder in RAS by absorbing aromatics from rejuvenators.

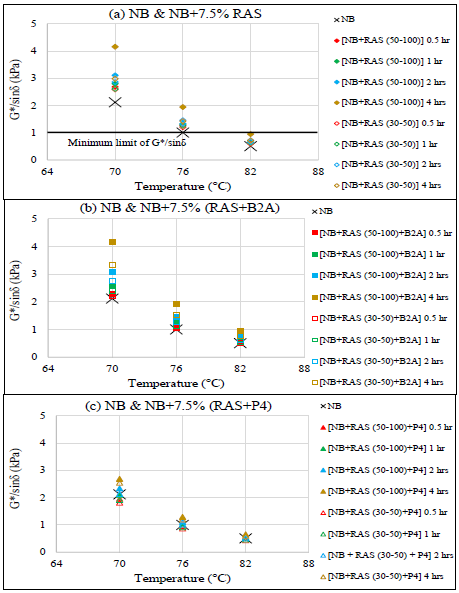

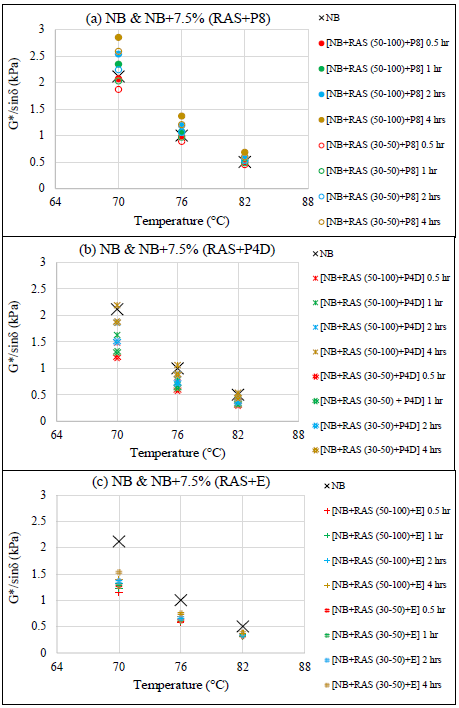

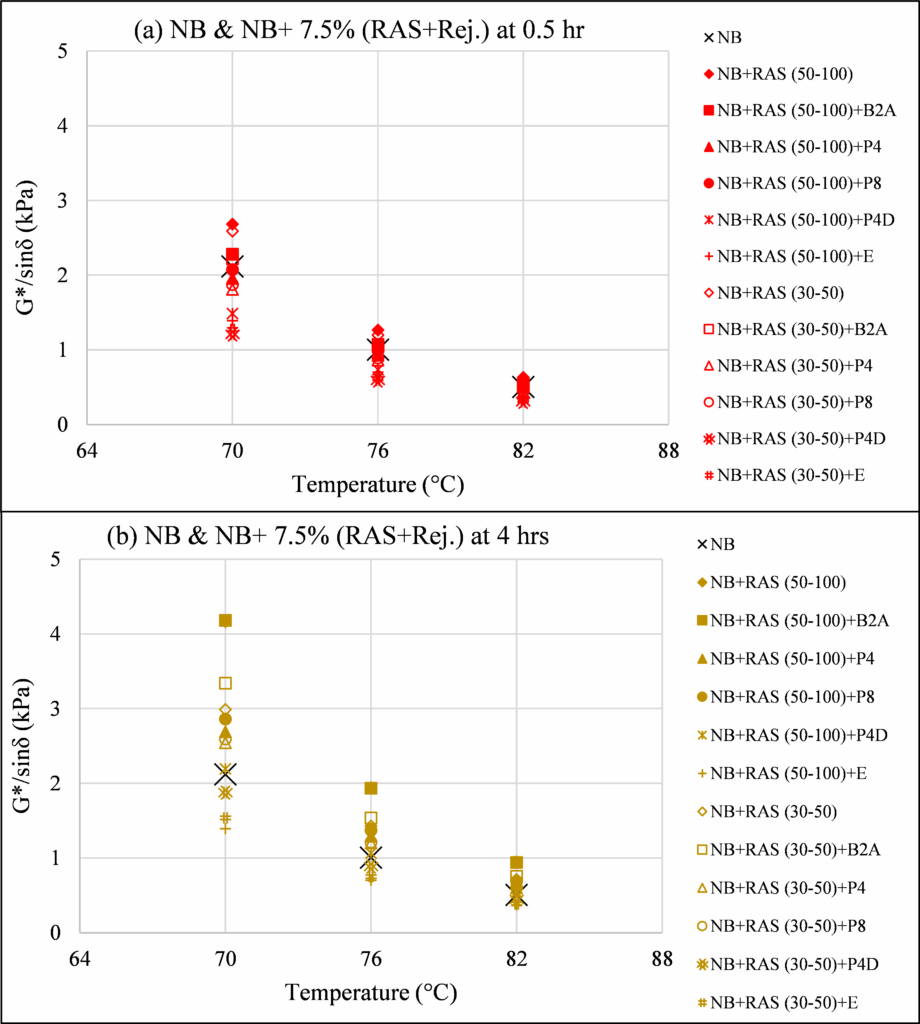

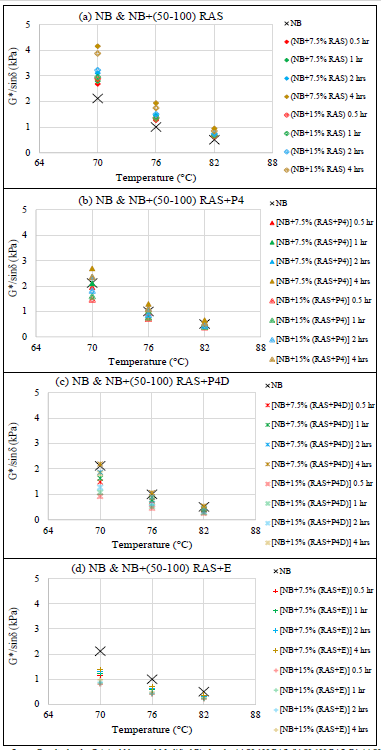

The rutting parameter (G*/sinδ) values obtained from the temperature sweep test results are represented in Figures 5 and 6 for the original neat and modified asphalt binders by 7.5% RAS or 7.5% RAS plus rejuvenators at different temperatures. Increasing the interaction time increased the G*/sinδ values of the modified binders because more compatibility took place between the RAS binder and neat binder, and more aromatics were lost from the rejuvenators. The modified binders with RAS (Figure 5-a) showed higher G*/sinδ values at different temperatures than that obtained for the neat binder because of the oxidized air-blown binder included in the RAS. Adding E and P4D oils to RAS counteracted the effect of the oxidized air-blown binder in the RAS by decreasing the stiffness of the modified asphalt binders (note Figures 6-b and 6-c). When comparing the modified binders with RAS+B2A, RAS+P4, and RAS+P8 in Figures 5-b, 5-c, and 6-a, the binder modified with RAS+P4 was the best choice because it has the lowest stiffness. As discussed earlier, the smallest RAS size (50-100) interacted more with the rejuvenators, causing more compatibility with the neat binder, than the largest size of RAS (30-50). That’s why modified binders with the RAS (50-100) showed more stiffnesses than the binders that interacted with the RAS (30-50). These results are confirmed with the temperature sweep test results presented in Figure 7 for the neat binder and modified binders by 7.5% RAS or 7.5% RAS plus rejuvenators and interacted at 0.5-hr and 4-hrs interaction times. Furthermore, increasing the interaction time from 0.5 hr in Figure 7-a to 4 hrs in Figure 7-b caused more compatibility between the neat binder and the RAS binder.

The effect of increasing the percentage of RAS or the interacted RAS with oils was explored in Figure 8. Doubling the percentage of RAS in asphalt binders increased the G*/sinδ values of the modified asphalt binders until 2-hrs interaction time (note Figure 8-a). At 4-hrs interaction time, the modified asphalt binder with 7.5% RAS showed higher G*/sinδ values than the modified asphalt binders with 15% RAS. This revealed that more interactions occurred between RAS and the neat binder at the 4-hrs interaction time for the sample modified by 7.5% RAS. This agrees with the results discussed in Figure 3: The modified binder with a 7.5% RAS had a lower mass loss percentage than the modified binder with a 15% RAS. For modified asphalt binders with RAS+P4, RAS+P4D, and RAS+E, increasing the percentage of the interacted RAS with oils from 7.5% to 15% showed a reduction in the G*/sinδ values because more aromatics were absorbed by the RAS particles.

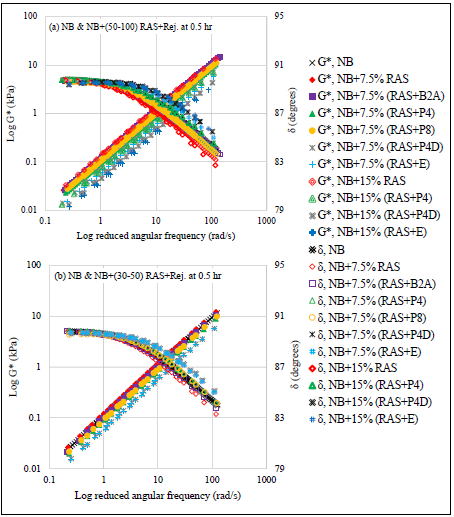

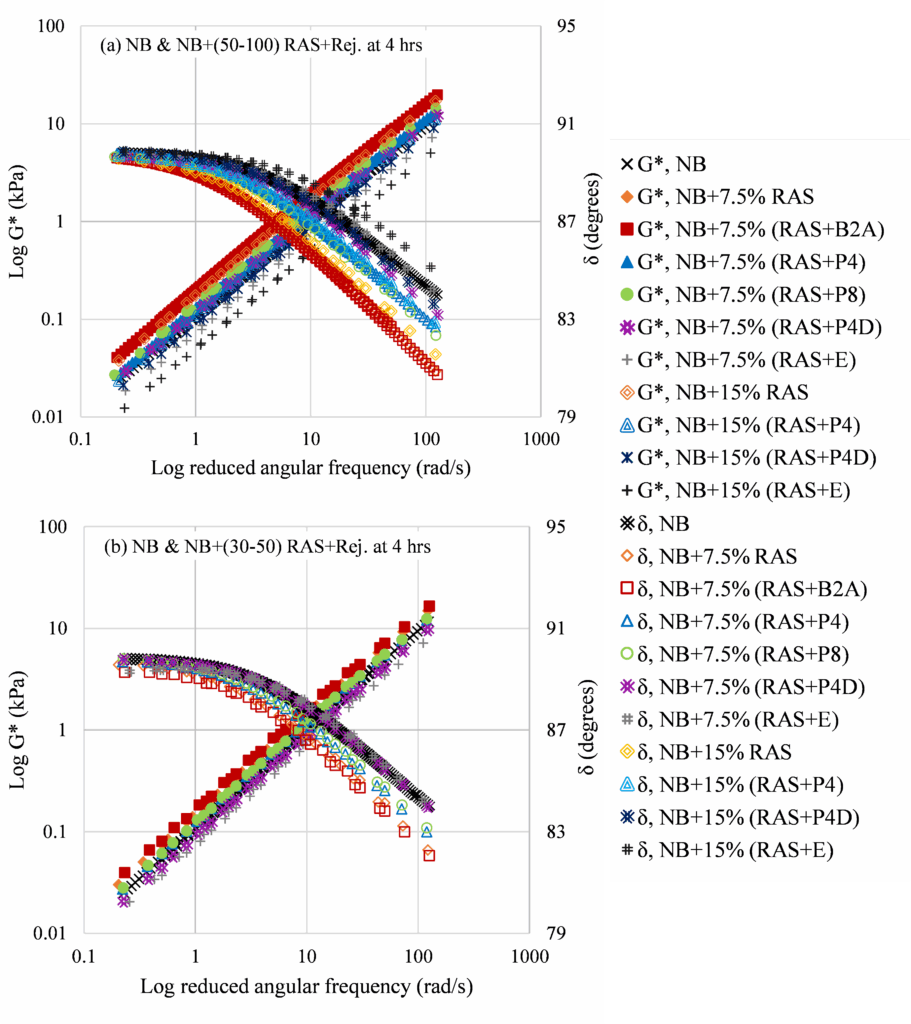

The master curves for the original neat and modified asphalt binders are presented in Figures 9 to 10. Two parameters were illustrated and measured at 76°C in these figures: The complex shear modulus (G*) and phase angle (d). The modified asphalt binders with RAS (50-100) showed higher stiffnesses (higher G*) and higher elasticities (lower d) than the asphalt binders modified with RAS (30-50), especially at the 4-hrs interaction time (Figure 10). Increasing the interaction time caused more stiffnesses and elasticities for the modified asphalt binders for two reasons: The first reason was the more interactions between the RAS and asphalt binders, and the second was due to the loss of aromatics included in the modified binders.

Generally, using RAS to modify the neat binder caused higher stiffness and elasticity values when compared to the neat binder values. Adding rejuvenators to the RAS decreased the stiffnesses and elasticities of the modified binders because of the effect of the low-molecular-weight fractions (aromatics) in the rejuvenators. When the B2A oil was added to the RAS, it did not introduce a superior enhancement in the G* and d values for the modified binders when compared to the values of the binders modified by the RAS only. However, the use of P4 and P8 oils with RAS to modify asphalt binder showed a better enhancement in the G* and d values, presenting lower G* and higher d values than the values of the asphalt binders modified by RAS only. The best enhancement in the G* and d values were obtained by interacting the RAS with P4D or E oil: The lowest G* and the highest d values were obtained for modified asphalt binders by RAS+E or RAS+P4D.

Increasing the RAS percentage from 7.5% to 15% caused an increase in the stiffness and elasticity values of the modified asphalt binder at a 0.5-hr interaction time due to the aged binder in the RAS. However, for RAS-modified binders that interacted at a 4-hrs interaction time, a binder with a lower RAS percentage (7.5%) had the highest stiffness and elasticity values than a binder with a higher RAS percentage (15%). This occurred because more interactions happened between RAS with a lower percentage and neat binder than between neat binder and a higher RAS percentage.

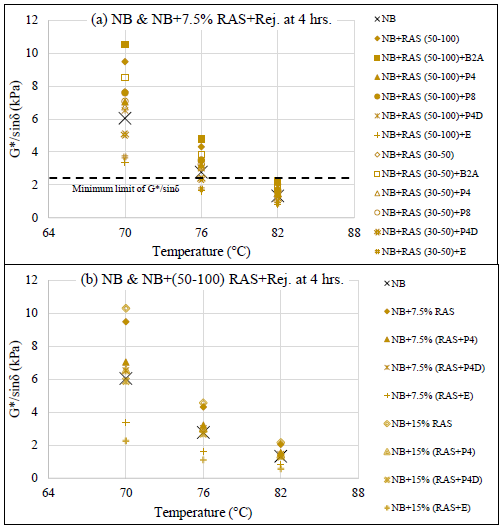

The temperature sweep test results for the RTFO neat and modified asphalt binders interacted at 4 hrs are displayed in Figure 11. The highest stiffnesses were for the modified asphalt binders with RAS+B2A and followed by the binders modified by RAS only. The lowest stiffness values were for the binder modified by RAS+E and followed by the binder modified by RAS+P4D. Furthermore, the general trend of most of the modified samples is that using RAS particles with smaller sizes caused more compatibility with the rejuvenators and neat binder than the RAS particles with larger sizes. That’s why the modified asphalt binders with the interacted (50-100) RAS had higher resistance to rutting than the resistance of the modified binders with the interacted (30-50) RAS. Using E oil with two sizes of RAS and P4D oil with a RAS size of 30-50 to modify the neat binder led to stiffnesses lower than the values of the neat binder. From Figure 11-b, increasing the RAS percentage from 7.5% to 15% caused higher stiffness values for the modified asphalt binders. More interactions happened between RAS and neat binder during the RTFO process, which revealed higher G*/sinδ values for the modified binder with the higher RAS content (15%). However, increasing the percentage of RAS that interacted with oils showed a reduction in the G*/sinδ values due to the softness effect of the absorbed oil by RAS.

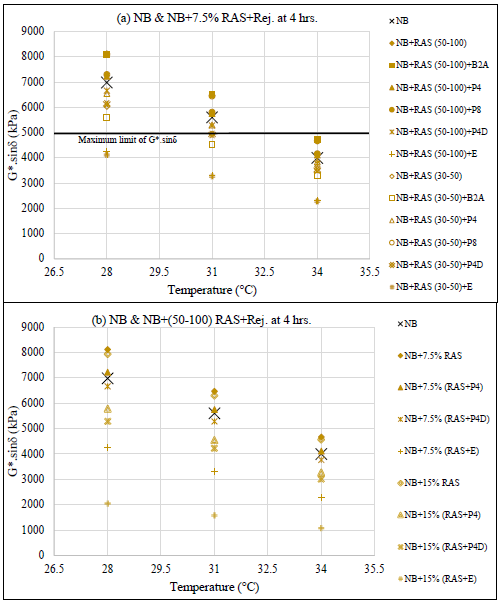

3.3. Intermediate-Temperature Rheological Results

The temperature sweep test results for the PAV neat and modified asphalt binders interacted at 4 hrs are shown in Figure 12. Using RAS with a size of 50-100 to modify the neat binder caused a deterioration in the fatigue resistance when compared to the neat binder by showing higher G*.sinδ values. However, using the same source of RAS with a larger size (30-50) showed better resistance to fatigue cracking than the neat binder. The best enhancement in fatigue cracking resistance was for the neat binders modified by RAS and E oil. Increasing the RAS or the interacted RAS with oils percentages in the modified asphalt binder showed higher resistance to fatigue cracking because of the effect of RAS and oils to decrease the G*.sinδ values.

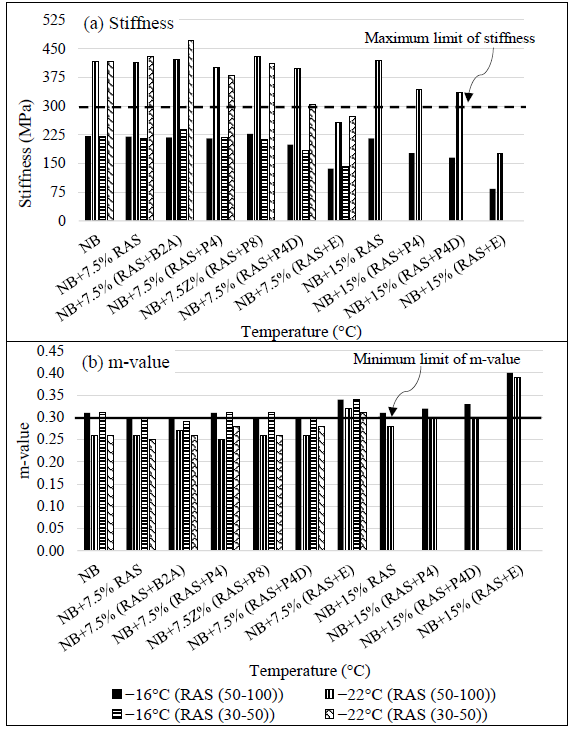

3.4. Low-Temperature Rheological Results

The low-temperature rheological properties at −16°C and −20°C of the PAV neat and modified asphalt binders interacted at 4 hrs are deemed in Figure 13. Using RAS with the neat binder did not significantly alter the low-temperature rheological properties of the modified asphalt binder. However, the use of RAS+B2A increased the stiffness values of the modified asphalt binder (Figure 13-a). The use of RAS+P4 and RAS+P4D decreased the stiffness of the modified asphalt binders. The best enhancement in the low-temperature rheological properties of the binders was obtained for the samples modified by RAS+E: These samples had the lowest stiffness values and the highest m-values. No specific trend could be observed when comparing the stiffness and m-value results of the modified binders by rejuvenators and two particle sizes of RAS. Increasing the RAS or the interacted RAS with oils in the modified binders enhanced the resistance to low-temperature cracking by showing higher m-values and lower stiffness values, which agrees with the intermediate-temperature cracking results.

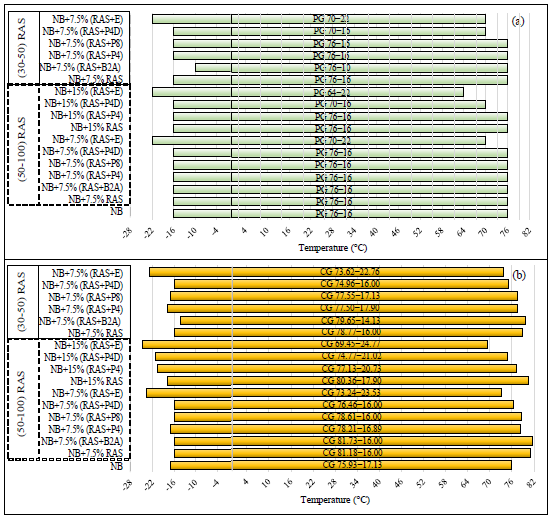

The PGs of the neat and modified asphalt binders are shown in Figure 14-a. The high PG temperatures did not change for most modified asphalt binders when compared to the value of the neat binder. However, the high PG temperatures decreased for binders that contained RAS+E or, in some samples, RAS+P4D when compared to the value of the neat binder. The low PG temperatures decreased for binders containing RAS+E by one grade when compared to the low PG temperature of the neat binder. The continuous grades (CGs) of the neat and modified asphalt binders are depicted in Figure 14-b. Using RAS or RAS+B2A increased the high CG and low CG temperatures of the modified binders when compared to the values of the neat binder. However, using RAS+E and RAS+P4D in asphalt binders showed the best enhancement in the high CG and low CG temperatures, followed by binders modified by RAS+P4 and RAS+P8.

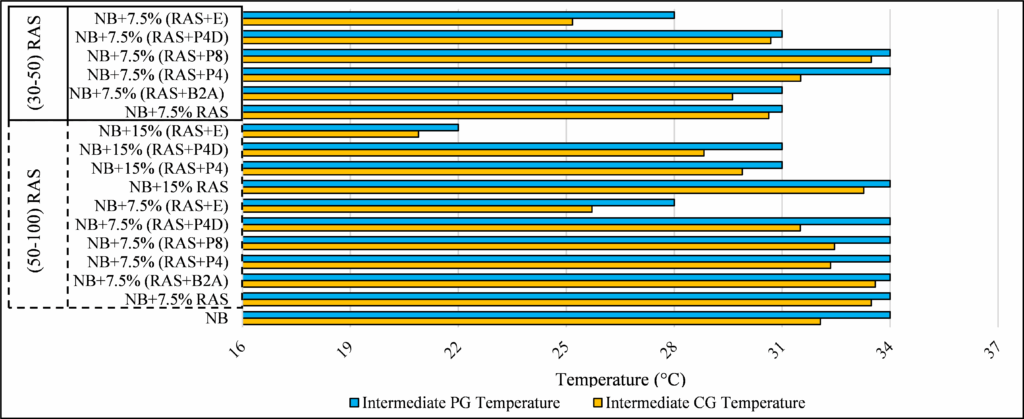

The intermediate PG and CG temperatures for the neat and modified asphalt binders are deemed in Figure 15. Using (50-100) RAS did not significantly alter the intermediate temperatures when compared to the value of the neat binder; however, the use of (30-50) RAS in asphalt binder enhances the fatigue resistance by showing lower intermediate temperatures when compared to the neat binder’s intermediate temperature. The best enhancement in the intermediate temperatures was obtained for binders modified by RAS+E and followed by RAS+P4D. These binders had the lowest intermediate PG and CG temperatures. Binders modified by (30-50) RAS had better fatigue resistance than binders modified by (50-100) RAS by presenting lower intermediate temperatures.

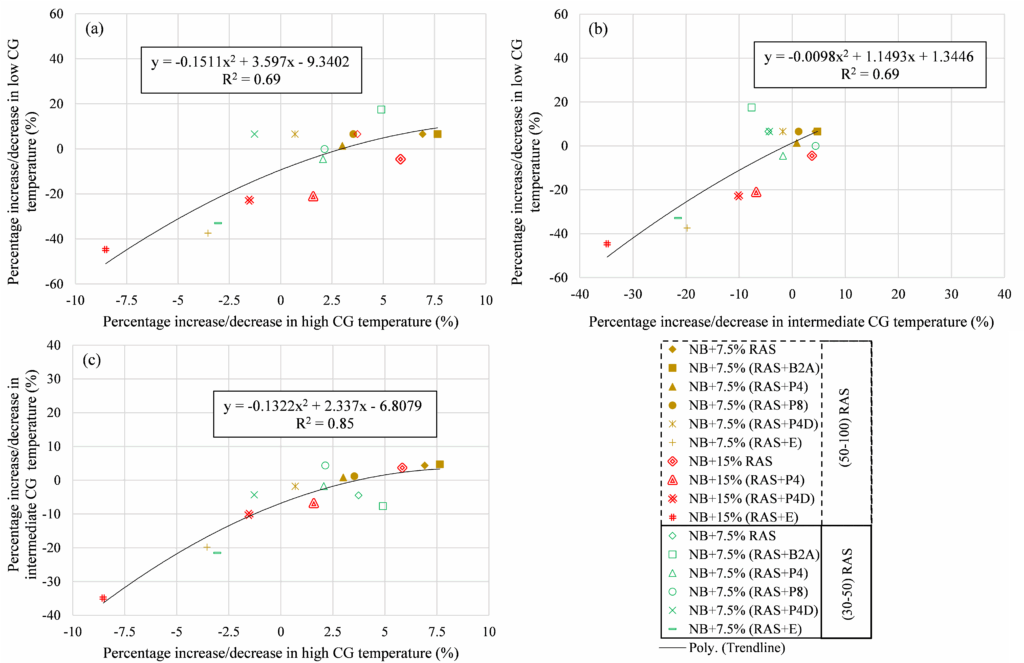

The relationships between the percentages of increase/decrease in high, intermediate, and low CG temperatures were evaluated and analyzed in Figure 16. These percentages were calculated for the CG temperatures of the modified asphalt binders at the 4-hrs interaction time when compared to the values of the neat binder. Direct relationships were observed between the percentages of increase/decrease in high, intermediate, and low temperatures. Modified asphalt binders with the highest percentage decrease in high CG temperature had the highest percentage decrease in low CG temperature and the highest percentage decrease in intermediate CG temperature (e.g., NB+15% (RAS+E)). Furthermore, it can be concluded that E oil counteracted the effect of the oxidized air-blown binder included in the RAS. Asphalt binders containing RAS+E have the highest percentage decrease in high, intermediate, and low CG temperatures. Thus, Evoflex as a commercial rejuvenator is recommended to be used with asphalt binders including RAS, when compared to the efficiency of other oils used in this study (pyrolysis oils). P4 oil is considered the best type among the pyrolysis oils that frustrated the negative impact of the oxidized air-blown binder in RAS.

3.5. Insoluble Asphalt Percentage Results

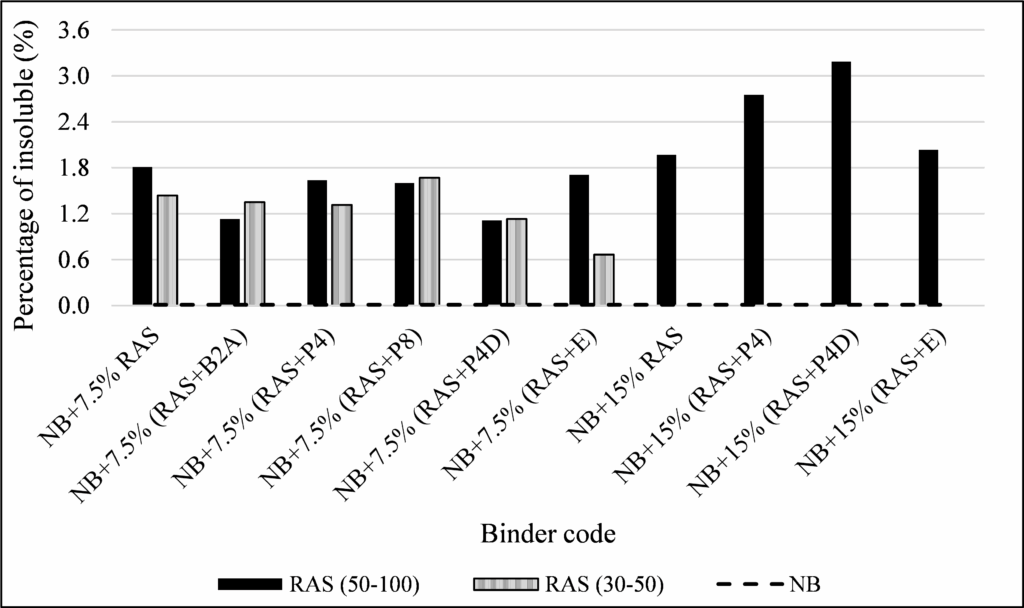

The insoluble asphalt percentages were shown in Figure 17 for the original neat and modified binders that interacted at 4 hrs. The insoluble percentage for RAS (30-50) was 84.3%, and the insoluble percentage for RAS (50-100) was 83.8%. The neat binder had the lowest percentage, with a value of 0.01%. The modified asphalt binders with 7.5% RAS or 7.5% RAS that interacted with oils had insoluble percentages of less than 1.8%, and these percentages were higher than the neat binder’s percentage because of the stiff binder in the RAS.

Moreover, increasing the RAS or the interacted RAS with oils in the modified binders increased the insoluble asphalt percentage. No specific trend was concluded when comparing the insolubility asphalt percentages of the modified binders with a 30-50 RAS plus oils or a 50-100 RAS plus oils.

4. Conclusions

An innovative technique was followed in this study to enhance the compatibility between RAS and asphalt binders. This was accomplished by interacting the milled RAS particles with rejuvenators to absorb low-molecular-weight fractions (aromatics) before mixing with the asphalt binder. Four pyrolysis oils and one recycling agent were used as rejuvenators. Based on this study, the following conclusions were reached:

- Interacting the milled RAS particles with rejuvenators decreases the stiffness of the oxidized air-blown binder in RAS by absorbing aromatics from rejuvenators

- Milled RAS with a particle size of 50-100 absorbed more oils, interacted more with oils, and were more compatible with the binder than RAS particles with a particle size of 30-50.

- Increasing the interaction time boosted the compatibility occurred between the RAS binder and neat binder.

- Adding Evoflex or P4D oils to RAS counteracted the impact of the oxidized air-blown binder in the RAS.

- By comparing the properties of the modified binders with RAS+B2A, RAS+P4, and RAS+P8, the modified binder with RAS+P4 was the best choice.

Conflict of Interest

The authors declare no conflict of interest.

Acknowledgment

The authors acknowledge the funding support of CarbonCycle LLC. for supporting the research and providing the pyrolysis oil samples.

- J. Davis, Using Recycled Asphalt Shingles in Asphalt Pavements. Asphalt: The magazine of the asphalt institute. http://asphaltmagazine.com/using-recycled-asphalt-shingles-in-asphalt-pavements/. Accessed July. 11, 2022.

- J.R. Willis, P. Turner, Characterization of Asphalt Binder Extracted from Reclaimed Asphalt Shingles, Publication NCAT Report 16-01, National Center for Asphalt Technology, Auburn, AL, USA, 2016.

- B. Rubino, An Investigative Look at the Effects of Post Consumer Recycled Asphalt Shingles on Soils and Flexible Pavements, M.Sc. Thesis, Iowa State University, Ames, IA, USA, 2010.

- W.G. Buttlar, M. Abdelrahman, H. Majidifard, E. Deef-Allah, Understanding and Improving Heterogeneous, Modern Recycled Asphalt Mixes, cmr 21-007, University of Missouri, Columbia, MO, USA, 2021.

- E. Deef-Allah, M. Abdelrahman, M. Ragab, “Components’ Exchanges between Recycled Materials and Asphalt Binders in Asphalt Mixes,” Advances. In Civil Engineering Materials, vol. 11, no. 1, pp. 20210105, 2022, doi:10.1520/ACEM20210105.

- E. Deef-Allah, M. Abdelrahman, “Evaluating the Low-Temperature Properties of Asphalt Binders Extracted from Mixtures Containing Recycled Materials,” Periodica Polytechnica Civil Engineering, vol. 66, no. 2, pp. 593–602, 2022, doi:10.3311/PPci.19681.

- G.W. Maupin, Investigation of the Use of Tear-Off Shingles in Asphalt Concrete, FHWA/VTRC 10-R23, Virginia Transportation Research Council, Charlottesville, VA, USA, 2010.

- E. Johnson, G. Johnson, S. Dai, D. Linell, J. McGraw, M. Watson, Incorporation of Recycled Asphalt Shingles in Hot-Mixed Asphalt Pavement Mixtures, MN/RC 2010-08, Minnesota Department of Transportation., Maplewood, MN, USA, Tech. 2010.

- R.C. Williams, A. Cascione, D.S. Haugen, W.G. Buttlar, R.A. Bentsen, J. Behnke, Characterization of Hot Mix Asphalt Containing Post-Consumer Recycled Asphalt Shingles and Fractionated Reclaimed Asphalt Pavement, Iowa State Univ., Ames, IA, 2011.

- A. Alvergue, M. Elseifi, L.N. Mohammad, S.B. Cooper, S. Cooper, “Laboratory Evaluation of Asphalt Mixtures with Reclaimed Asphalt Shingle Prepared Using the Wet Process,” Road Materials and Pavement Design, vol. 15, no. sup1, pp. 62–77, 2014, doi:10.1080/14680629.2014.927410.

- F. Zhou, H. Li, S. Hu, J. W. Button, J.A. Epps, Characterization and Best Use of Recycled Asphalt Shingles in Hot-Mix Asphalt, FHWA/TX-13/0-6614-2, Texas A&M Transportation Institute, College Station, TX, USA, 2013.

- R. West, N. Tran, A. Kvasnak, B. Powell, P. Turner, “Construction and Field Performance of Hot Mix Asphalt with Moderate and High RAP Contents,” in Bearing Capacity Roads, Railways Airfields. 8th Int. Conf. (BCR2A’09), Champaign, IL, USA, pp. 1373–1381, 2009, doi:10.1201/9780203865286.ch143.

- M.Z. Alavi, D. Jones, Y. He, P. Chavez, Y. Liang, Investigation of the Effect of Reclaimed Asphalt Pavement and Reclaimed Asphalt Shingles on the Performance Properties of Asphalt Binders: Phase 1 Laboratory Testing, UCPRC-RR-2016-06, University of California Pavement Research Center, Davis, CA, USA, 2016.

- E. Deef-Allah, M. Abdelrahman, “Characterization of Asphalt Binders Extracted from Field Mixtures Containing RAP and/or RAS,” World Journal of Advanced Research and Reviews, vol. 13, no. 1, pp. 140–152, 2022, doi:10.30574/wjarr.2022.13.1.0729.

- E. Deef-Allah, M. Abdelrahman, “Interactions between RAP and Virgin Asphalt Binders in Field, Plant, and Lab Mixes,” World Journal of Advanced Research and Reviews, vol. 13, no. 1, pp. 231–249, 2022, doi:10.30574/wjarr.2022.13.1.0744.

- E. Deef-Allah, M. Abdelrahman, “Optimizing Percentages of Asphalt Content Extracted from Mixes Containing RAP and/or RAS,” Journal of Engineering Research and Reports, vol. 21, no. 11, pp. 11–29, 2021, doi:10.9734/jerr/2021/v21i1117500.

- M. Mohammadafzali, H. Ali, J.A. Musselman, G.A. Sholar, A. Massahi, “The Effect of Aging on the Cracking Resistance of Recycled Asphalt,” Advances in Civil Engineering, vol. 2017, pp. 1–7, 2017, doi:10.1155/2017/7240462.

- R. Rahbar-Rastegar, “Cracking in Asphalt Pavements: Impact of Component Properties and Aging on Fatigue and Thermal Cracking,” Ph.D. Dissertation, University of New Hampshire, NH, USA, 2017.

- M.A. Elseifi, A. Alvergue, L.N. Mohammad, S. Salari, J.P. Aguiar-Moya, S.B. Cooper, “Rutting and Fatigue Behaviors of Shingle-Modified Asphalt Binders,” Journal of Materials in Civil Engineering, vol. 28, no. 2, pp. 04015113, 2016, doi:10.1061/(ASCE)MT.1943-5533.0001400.

- A.R. Abbas, U.A. Mannan, S. Dessouky, “Effect of Recycled Asphalt Shingles on Physical and Chemical Properties of Virgin Asphalt Binders,” Construction and Building Materials, vol. 45, pp. 162–172, 2013, doi:10.1016/j.conbuildmat.2013.03.073.

- E. Deef-Allah, M. Abdelrahman, “Investigating the Relationship between the Fatigue Cracking Resistance and Thermal Characteristics of Asphalt Binders Extracted from Field Mixes Containing Recycled Materials,” Transportation Engineering, vol. 4, pp. 100055, 2021, doi:10.1016/j.treng.2021.100055.

- E. Deef-Allah, M. Abdelrahman, “Thermal, Chemical and Rheological Properties of Asphalt Binders Extracted from Field Cores,” Innovative Infrastructure Solutions, vol. 7, no. 235, 2022, doi:10.1007/s41062-022-00836-6.

- H.U. Bahia, D. Swiertz, Design System for HMA Containing a High Percentage of RAS Material. University of Wisconsin-Madison Madison, WI, USA, 2011.

- E. Deef-Allah, M. Abdelrahman, M. Fitch, M. Ragab, M. Bose, X. He, “Balancing the Performance and Environmental Concerns of Used Motor Oil as Rejuvenator in Asphalt Mixes,” Recycling, vol. 4, no. 1, 2019, doi:10.3390/recycling4010011.

- E. Deef-Allah, M. Abdelrahman, “Effect of Used Motor Oil as a Rejuvenator on Crumb Rubber Modifier’s Released Components to Asphalt Binder,” Progress in Rubber, Plastics and Recycling Technology, vol. 37, no. 2, pp. 87–114, 2021, doi:10.1177/1477760620918600.

- E. Deef-Allah, M. Abdelrahman, “Balancing the Performance of Asphalt Binder Modified by Tire Rubber and Used Motor Oil,” International Journal of Recent Technology and Engineering, vol. 8, no. 4, pp. 5501–5508, 2019, doi:10.35940/ijrte.D8893.118419.

- G. Guduru, C. Kumara, B. Gottumukkala, K.K. Kuna, “Effectiveness of Different Categories of Rejuvenators in Recycled Asphalt Mixtures,” Journal of Transportation Engineering, Part B: Pavements, vol. 147, no. 2, pp. 04021006, 2021, doi:10.1061/JPEODX.0000255.

- G. Zhang, F. Chen, Y. Zhang, L. Zhao, J. Chen, L. Cao, J. Gao, C. Xu, “Properties and Utilization of Waste Tire Pyrolysis Oil: A Mini Review,” Fuel Processing Technology, vol. 211, pp. 106582, 2021, doi:10.1016/j.fuproc.2020.106582.

- D. Czajczyńska, R. Krzyżyńska, H. Jouhara, N. Spencer, “Use of Pyrolytic Gas from Waste Tire as a Fuel: A Review,” Energy, vol. 134, pp. 1121–1131, 2017, doi:10.1016/j.energy.2017.05.042.

- A. Kumar, R. Choudhary, A. Kumar, “Evaluation of Waste Tire Pyrolytic Oil as a Rejuvenation Agent for Unmodified, Polymer-Modified, and Rubber-Modified Aged Asphalt Binders,” Journal of Materials in Civil Engineering, vol. 34, no. 10, 2022, doi:10.1061/(ASCE)MT.1943-5533.0004400.

- P.T. Williams, “Pyrolysis of Waste Tyres: A Review,” Waste Management, vol. 33, no. 8, pp. 1714–1728, 2013, doi:10.1016/j.wasman.2013.05.003.

- ASTM D2872-19, “Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test),” West Conshohocken, PA: ASTM International, 2019, doi:10.1520/D2872-19.

- ASTM D6521-19a, “Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV),” West Conshohocken, PA: ASTM International, 2022, doi: 10.1520/D6521-19A.

- ASTM D7175-15, “Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer,” West Conshohocken, PA: ASTM International, 2015, doi:10.1520/D7175-15.

- ASTM D7405-20, “Standard Test Method for Multiple Stress Creep and Recovery (MSCR) of Asphalt Binder Using a Dynamic Shear Rheometer,” West Conshohocken, PA: ASTM International, 2020, doi:10.1520/D7405-20.

- ASTM D6648-08, “Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR),” West Conshohocken, PA: ASTM International, 2016, doi: 10.1520/D6648-08.

- ASTM D2042-22, “Standard Test Method for Solubility of Asphalt Materials in Trichloroethylene or Toluene,” West Conshohocken, PA: ASTM International, 2022, doi:10.1520/D2042-22.

- Eslam Deef-Allah, Magdy Abdelrahman, “Trajectory Correction Method of Motion Description Language of Vertebral Milling Robot based on Force Feedback”, Journal of Engineering Research and Sciences, vol. 1, no. 10, pp. 26–35, 2022. doi: 10.55708/js0110005