Cloud ERP vs. On-Premise QAD ERP: A Cost-Benefit Analysis for Mid-Sized Manufacturers

Journal of Engineering Research and Sciences, Volume 4, Issue 7, Page # 1-14, 2025; DOI: 10.55708/js0407001

Keywords: Costs & Benefits Analysis, Mid-Sized Manufacturers, On-Premise QAD ER, Cloud ERP, Enterprise Software, Digital Transformation, Total Cost of Ownership (TCO)

(This article belongs to the Section Information Systems – Computer Science (ISC))

Export Citations

Cite

Jaiswal, R. (2025). Cloud ERP vs. On-Premise QAD ERP: A Cost-Benefit Analysis for Mid-Sized Manufacturers. Journal of Engineering Research and Sciences, 4(7), 1–14. https://doi.org/10.55708/js0407001

Ravi Jaiswal. "Cloud ERP vs. On-Premise QAD ERP: A Cost-Benefit Analysis for Mid-Sized Manufacturers." Journal of Engineering Research and Sciences 4, no. 7 (July 2025): 1–14. https://doi.org/10.55708/js0407001

R. Jaiswal, "Cloud ERP vs. On-Premise QAD ERP: A Cost-Benefit Analysis for Mid-Sized Manufacturers," Journal of Engineering Research and Sciences, vol. 4, no. 7, pp. 1–14, Jul. 2025, doi: 10.55708/js0407001.

1. Introduction

Enterprise Resource Planning (ERP) systems act as the technological bedrock of digital manufacturing by unifying core business processes such as inventory control, procurement, production planning, and financial management in a single system. Due to the increasing competition and speed of manufacturing system operations, ERP systems are necessary to have real-time data visibility and coordination to optimize operations and enable informed decision-making. With the global supply chains growing ever more complex, mid-sized manufacturers increasingly rely on ERP systems to manage the workflows, follow compliance, and act on fast market conditions [1]. With the advent of Industry 4.0, the relevance and need for ERP have gone up manifold to ensure seamless connectivity and data-driven operations are terms that are no longer optional but indispensable for business growth.

ERP systems historically operated On-Premise, requiring a large financial commitment upfront for hardware, software, and IT personnel [2]. Deep customization and control came at high maintenance expenses and long implementation times in QAD On-Premise models. Cloud computing will give rise to a radical change in ERP deployment. ERP SaaS solutions operate in the cloud and offer flexible, scalable platforms that can be accessed off-site and maintained by the vendor. These systems eliminate a great deal of IT overhead and speed up deployment while giving you frequent updates [3]. Today, cloud ERP is rapidly being adopted in almost all industries because of the promise of agility, lower total cost of ownership (TCO), and integration with emerging digital tools [2].

Midsize industrial companies dominate the industrial landscape. They are typically large enough to need quite complicated systems to run operations but small enough to feel the financial and operational strain of every technological investment. Usually, these firms have a small number of IT resources and therefore find the maintenance-heavy systems difficult to continue. But at the same time, they are ambitious, they want to go past scale, global competition, and digital transformation to future-proof their business. ERP decisions are critical and influence nearly every business function because these decisions must be balanced against the need for strategic growth with the cost sensitivity of mid-sized firms [4]. The ERP system may either speed up or slow down the transition to smart manufacturing and operational efficiency.

Table 1: Comparison of IT Resources, Budgets, and Needs by Firm Size

Category | Small Manufacturers | Mid-Sized Manufacturers | Large Manufacturers |

IT Staff | 1–3 generalists | 4–10 specialists/generalists | 10–50+ specialists (internal departments) |

Annual IT Budget | <$100,000 | $100,000 – $1 million | $1 million – $10+ million |

ERP Customization | Minimal; prefers off-the-shelf | Moderate; seeks industry-specific tweaks | High; extensive customization |

Scalability Needs | Low to moderate | High – planning for growth | Very high – often multinational |

Security Requirements | Basic compliance-focused | Industry-specific compliance & audits | Comprehensive, includes global standards |

Deployment Flexibility | High (cloud preferred) | Balanced (cloud or hybrid options) | Often On-Premise or Hybrid |

Downtime Tolerance | Moderate | Low | Very low |

Moreover, there is a dilemma for mid-sized manufacturers who need to decide between a modern cloud QAD ERP solution and a historic On-Premise QAD system. QAD comes with plenty of features that are tried and testable but require a lot of money and IT support [5]. On the other hand, cloud ERP solutions are flexible and offer lower upfront costs; however, some of the disadvantages of this include data security, integrations with legacy systems, and vendor lock-in.

There is no easy decision here, factoring in the place that you are currently at in terms of digital maturity, your growth goals, and your risk tolerance. Often, however, manufacturers must choose between long-term strategic value and short-term feasibility, and thus an objective cost-benefit analysis is not only useful but essential [6].

However, despite growing interest in such ERP modernization, little research has focused explicitly on midsized manufacturers. ERP studies either generalize findings to all firms’ sizes or focus on the largest firms whose resource capabilities greatly differ from the study context. This leaves a knowledge gap that gives mid-sized companies the grounds to make decisions based either on anecdotal evidence, vendor persuasion, or incomplete financial forecasting. In addition, most other comparisons frequently portray terms and elements instead of including the overall economic influence and scalability over time [7]. The tangible and intangible costs and benefits of cloud ERP and On-Premise QAD in a mid-sized organization are clearly in need of research that rigorously evaluates their existence.

Table 1 shows the different IT environments and strategic needs among Manufacturing Firms of different sizes. Small manufacturers typically have few employees or a small budget when it comes to IT and, in turn, are inclined to pick simple, inexpensive ERP solutions with minimal customization [8]. Other, mid-sized manufacturers, for example, are in a transitional context, wanting to grow operations and compete at a higher level while still having constrained budgets and staffing. Capable of high levels of customization and scalability, secure and mature across the enterprise, but affordable enough to not require internal resources to be overwhelmed [7]. However, unlike small manufacturers, huge manufacturers have well-utilized IT departments and ample budgets to expend on highly personalized, integrated, secure ERP paraphernalia that is deployed either On-Premise or hybrid environments. This puts us in the context of why mid-sized firms have a truly complex decision point for choosing between Cloud and On-Premise ERP application.

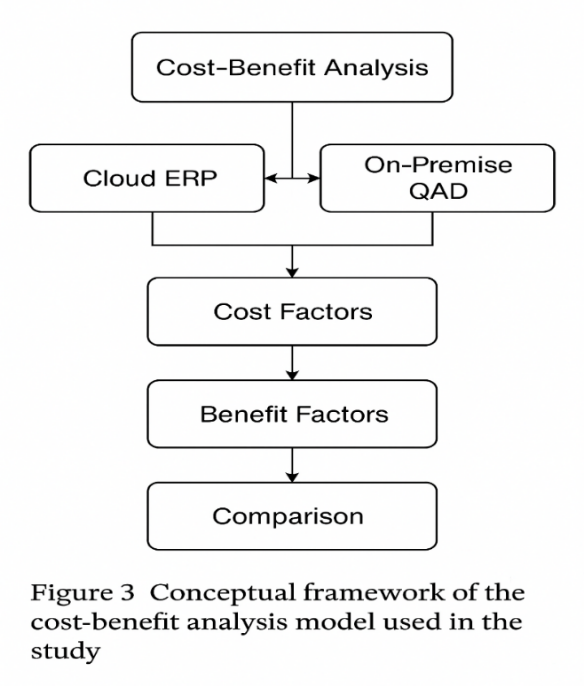

Figure 1 displays the conceptual framework of the cost-benefit analysis model used in this study. First, we have two ERP deployment options: Cloud ERP and On-Premise QAD. Next, there are five key evaluation criteria: initial investment, operational costs, scalability, integration capability, and long-term ROI. They are then evaluated under a quantitative lens (e.g., TCO modeling) and a qualitative lens (e.g., user satisfaction). It builds upon this by creating opportunities for a comparative analysis of the outcomes and supports strategic decision-making for midsized manufacturers to be matched with their digital maturity, resource capacity, and respective growth objectives [9].

The purpose of this study is to address the research gap by conducting a comprehensive cost-benefit comparison of cloud ERP versus On-Premise QAD for mid-sized manufacturing firms. The research analyzes TCO, integration capabilities, operational efficiencies, and ROI over 5 years using both quantitative and qualitative data [9]. Vendor pricing models, industry benchmarks, and expert interviews were combined to gather data. Their goal is to equip mid-sized manufacturers with actionable insights from financial modeling and real-world feedback. This will inform mid-sized manufacturers’ ERP decision-making in a manner that the mid-sized manufacturers’ strategic goals, resource capabilities, and digital transformation journey will permit [10].

This study is specifically about QAD ERP because it addresses a distinct and under-explored niche and fills a gap in research on the specific ERP demands of global manufacturing companies, especially in highly regulated and rapidly changing industries like automotive, health sciences, consumer products, and industrial manufacturing. There is a noticeable lack of scholarly and practical study on industry-specific ERP systems like QAD ERP, especially in the context of manufacturing-focused businesses, despite the wealth of literature on SAP, Oracle, and Microsoft Dynamics ERP deployments. By comparing QAD’s deployment models—Cloud vs. On-Premise—in a manufacturing setting, this study fills that knowledge vacuum. This study examines deployment choices from the perspectives of operational requirements, infrastructure preparedness, and cost-effectiveness for mid-sized manufacturing companies, in contrast to broader ERP evaluations.

QAD has been explicitly adopted by mid-sized manufacturers, more so in those that necessitate traceability, regulation, and high customization of their manufacturing operations. Because of its specificity, unlike other more general software applications (SAP or Oracle), QAD is regarded as one of the best software packages in discrete manufacturing locales, which is why it can be considered an adequate yardstick to test software products in companies with limited IT capabilities but advanced production processes. In areas, such as North America and the Asia-Pacific regions, QAD still has a significant share of the medium-sized organizations because of the long-term On-Premise history and increasing cloud-native modules. It is hence particular to this cost benefit inquiry.

2. Methodology

This study makes a comparative cost-benefit analysis of Cloud ERP systems and On-Premise QAD ERP system based on the context of midsized manufacturers. It aims to make sense of both tangible and intangible factors on a 5-year horizon with a broadened view of long-term value. The benefits considered for as many cost elements (capital expenditure, maintenance fees, and hidden implementation costs, for instance) are scalability, deployment speed, integration ease, and return on investment (ROI). In the model, technical can translate into business and vice versa; both financial modeling and stakeholder insights are integrated into the model to ensure that technical outcomes are appropriate as per business implications. This grounded methodology provides a dual approach to support ERP strategic decisions based on both economic logic and practical relevance.

Tables 2 and 3 below detail the performance benchmarks and infrastructure specifications for both On-Premise and Cloud-based ERP deployments. Adding these performance and infrastructure specs is important for putting the deployment trade-offs in context, especially in industrial settings where uptime, integration, and IT costs are very important. These benchmarks not only help with Total Cost of Ownership (TCO) models, but they also help stakeholders figure out if something is technically possible based on the size of the business, the industry, and the rules that must be followed.

Table 2: Performance and Equipment Specifications for On-Premise QAD ERP deployment

Requirement Category | Specification/Minimum Requirement |

Application Server | Quad-core Xeon or AMD EPYC processor, 32–64 GB RAM, SSD storage |

Database Server | Same or higher than application server specs; PostgreSQL or Oracle DB supported |

Client Devices | Dual-core CPU, 4 GB RAM, modern browser or QAD .NET UI client |

Network Infrastructure | Gigabit LAN; secure VPN for remote access |

Storage Capacity | Minimum 1 TB RAID-configured storage with automated backups |

Backup & DR | Daily incremental + weekly full backups; local and off-site DR plan |

OS Requirements | RHEL/CentOS 7+ or Windows Server 2019+ |

IT Staffing | Minimum of 1–2 full-time IT administrators for mid-sized deployment |

Table 3: Performance and Equipment Specifications for Cloud-based QAD ERP deployment

Requirement Category | Specification/Minimum Requirement |

Network Bandwidth | Minimum 10 Mbps per user; 50+ Mbps for mid-sized operations |

Latency | <100 ms round-trip time to QAD Cloud Data Center |

Client Hardware | Any modern desktop/laptop with dual-core CPU, 4 GB RAM, and HTML5-compatible browser (e.g., Chrome, Firefox, Edge) |

Redundancy & Uptime | 99.9% uptime SLA with geo-redundant backups and failover support |

Storage Scalability | Elastic storage based on usage; initial allocation ~500 GB per tenant for core data |

Security Compliance | SOC 2, ISO 27001, GDPR, HIPAA (industry-dependent) |

Integration | Supports REST APIs, EDI, and native connectors for MES, WMS, PLM |

2.1. Data Sources

2.1.1. Primary Data Surveys

Structured interviews with IT managers from 5 midsized manufacturing firms were conducted to gain operational insights into the deployment and performance of ERP systems. Each interview took around 45–60 minutes and followed a semi-structured format, asking for information on the performance of the system, implementation challenges, flexibility of customizing the system, and post-implementation support.

IT managers provided their experience or direct comparisons for Cloud ERP and On-Premise QAD, which provided thorough assessments. The companies on which the cases were found were automobile parts, packaging, textiles, industrial equipment, and consumer goods, and they served to offer a variety of viewpoints. They confirmed important operational issues including downtime risk, user training, and responsiveness of disembarking systems as well as the technical assumptions on which the cost-benefit model depended on.

An analysis of the budgetary and long-term investment implications of ERP deployment was conducted based on interviews with financial officers. These professionals also helped avoid hidden costs like vendor lock-in, licensing fluctuations, and integration costs for third-party platforms. The interviews, lasting from 30 to 45 minutes, also viewed how ROI was monitored and tracked on time. Financial officers consistently demanded ERP products and services that have traded affordability for the ability to enable growth. Others pointed to the unfair burden of unexpected upgrade costs and the difficulties in calculating TCO for hybrid deployments. Furthermore, their insights added to how the two systems played with their financial trade-offs and the need to be predictable in costs and scalable in the long run for mid-sized firms [7].

Along with interviews, a 50-person survey was administered to ten mid-sized firms that use Cloud ERP or On-Premise QAD ERP. The main areas of interest for the survey were user satisfaction, perceived system reliability, adaptability, and ease of use. Statistical analysis of responses was conducted by using SPSS (Statistical Package for the Social Sciences). Our findings show that users prefer Cloud ERP regarding ease of updating and ease of interface accessing, and QAD users are more satisfied with system stability and control. These user-level insights added a behavioral dimension to the cost-benefit model by adding a dimension of the behavioral impact of end-user experience on productivity and overall system effectiveness. The response rate was 86%, with strong engagement and reliability of data.

Follow-up questions were issued to select participants after the survey to further deepen understanding of contextual variables. These included questions regarding timelines for data migration, the amount of vendor support during crisis, and downtime recovery. The responses provide a nuanced context, giving variability in performance between ERP systems based on industry type, digital maturity, and IT staffing levels. For example, firms with lean IT teams tended to favor Cloud ERP for its vendor-managed infrastructure, while those with regulatory-heavy environments leaned toward On-Premise QAD for compliance reasons. These follow-ups were essential in identifying the operational trade-offs that may not be immediately evident in financial analysis alone.

2.1.2. Secondary Data Survey

The secondary data collection started by reviewing in detail the vendor pricing spreadsheet and the product specification document from the leading cloud ERP providers and QAD. What these documents provided was critical baseline information on license costs, subscription models, user limits, implementation support, upgrade cycles, etc. The pricing data was normalized so that different systems and different vendors could compare on the same scale.

A subscription fee analysis was performed for small (10 users), medium (50 users), and large (100+ users) deployments of Cloud ERP. Ten-year examples of one-time licensing and ongoing maintenance were calculated for QAD. It enabled TCO modeling with accuracy as well as insight regarding the ways that pricing structure impacts ERP affordability and ROI over time.

Case studies of published sources such as Gartner (https://www.gartner.com/en/documents/4800931), Forrester (https://www.forrester.com/), and Deloitte (https://www2.deloitte.com/insights/us/en.html) were chanced on to contextualize the financial and operational impact of an ERP adopter in the middle-sized manufacturing context. The outcomes we have seen in these case studies are things like implementation duration, performance KPIs, and user adoption trends. Case studies focused on the failure of On-Premise upgrades and the agility of cloud deployments. To make sure that analysis of such findings remained grounded in industry realities today, triangulation with primary data was used. Secondly, the case studies also acted as benchmarks to validate or question vendor document assumptions, thus making for a much more balanced evaluation framework.

To understand ERP adoption and associated satisfaction levels and financial results across the market, it used such reports as the Panorama Consulting ERP Report (https://www.panorama-consulting.com) and Aberdeen Group’s ERP Trends survey (https://www.aberdeen.com). The benefit from these reports can be reflected in the ability to provide large-scale data points for average times to implementation, cost overruns, ROI timeline, and failure rates.

Our cost-benefit model was calibrated using data from these sources, and we used this data to find anomalies in the primary data. This includes, for example, vendors claiming average deployment times of 4–6 months while benchmarking reports revealed that midsized manufacturers deployed QAD in 12 months or more. This discrepancy was factored into the adjusted TCO and ROI calculations, lending credibility and depth to the final analysis.

2.2. Metrics analyzed

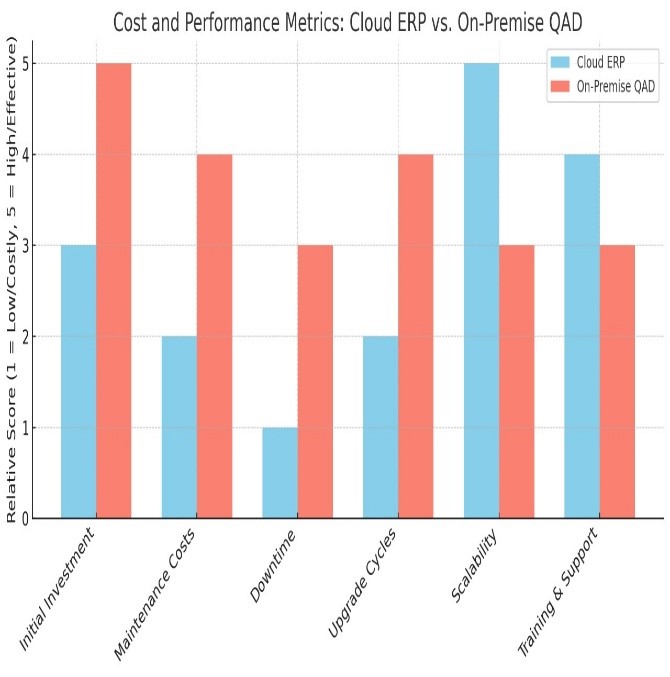

Figure 2 shows a bar graph that contrasts the key metrics for Cloud ERP and On-Premise QAD ERP, including initial investment, maintenance costs, downtime, upgrade cycles, scalability, and training & support. The performance and cost-effectiveness of each metric is scored on a relative scale from 1 (low/costly or inefficient) to 5 (highly effective or affordable). In most categories, Cloud ERP (score of 5 vs. On-Premise QAD score of 3) performs the best in scalability, training & support (4 vs. 3), and maintenance costs (2 vs. 4). These findings suggest that, overall, Cloud ERP is more accommodating, quicker, and easier to maintain and has better support, and therefore it is suitable for improvement of mid-sized manufacturers’ operations without significant initial or continuing investment in IT. However, On-Premise QAD shows slightly higher scores in areas like control and customization, especially during early setup.

2.2.1. Initial Investment

Typically, cloud ERP systems need less upfront investment as compared to On-Premise QAD ERP. This is because the Software as a Service (SaaS) model used by the subscription is resource intensive. It also means no more cost of great hardware like servers, dedicated hardware, and in-house data centers [11]. It is a model that appeals to mid-sized manufacturers who wish to enter the ERP space without making a huge capital expenditure (CapEx). The licensing itself tends to be flexible (scale up or down according to the number of users), and there often exist initial implementation services that are included in your subscription tiers, so the financial threshold to get involved is generally low. This is important for those firms wishing for rapid deployment or performance testing before adoption.

In contrast, On-Premise QAD solutions entail a substantial initial investment. It involves expenses for organizations that will have to procure and maintain the physical infrastructure to host the software [12]. Further, we have costs related to licensing, hiring implementation consultants, and placing cybersecurity factors in place. Huge costs that can run into hundreds of thousands of dollars, just for a mid-size company must be paid up front.

Unlike cloud systems, QAD also requires upfront purchases of perpetual licenses, often accompanied by costly customization and integration services. As such, the cost burden is heavier in the early stages, making On-Premise systems a less flexible option for firms with tighter budgets or uncertain growth trajectories.

2.2.2. Maintenance Costs

Cloud ERP platforms eliminate much of the ongoing maintenance burden for mid-sized firms [5]. The internal IT team is not involved much because the vendor deals with updates, security patches, and server management. This results in saving both direct costs and time otherwise taken to keep the system operating. These services are part of this predictable monthly or annual subscription and allow for clear forecasting of costs.

Furthermore, when the cloud vendor has 24/7 support with automated diagnostics, surprise expenses caused by technical failure or downtime are minimized [13]. When looking out over a 5-year horizon, this means significant savings and increased attention on core business operations instead of required and costly infrastructure upkeep.

However, On-Premise QAD systems require high and continuous maintenance. Some of them are internal hardware servicing, software updates, database backups, and cybersecurity upgrades, both internally and via outsourced support [14]. To keep or hire these individuals, fees are high, especially since firms must retain or contract IT specialists to handle these tasks. Additionally, a missed update or even a configuration error leads to system instability or even security vulnerabilities. They apply to annual maintenance fees of 15–20 percent of the original license cost, too. The combination effect of these factors makes it expensive and resource-intensive to maintain On-Premise solutions [15]. These are key things to consider when run by mid-sized businesses with a distinct lack of dedicated IT staff or failure to anticipate disaster recovery.

2.2.3. Downtime

Productivity and revenue suffer while downtime happens, so it is a metric that needs to be tracked [16]. Cloud ERP systems are more uptime-oriented, which means they are typically positioned to run with a very high or 99.9 percent and above uptime. This is because they are based on global data centers, redundancy protocols, and round-the-clock monitoring. When something disrupts, cloud vendors run rapid fixes and reroute the data to alternate servers. This reliability is key for companies that do tight production timelines or companies that serve just-in-time supply chains. It also facilitates automated system monitoring that can identify and resolve performance issues before they reach the level of outages [17]. Resiliency like this has operational continuity benefits and cuts indirect costs related to halts in workflow or delayed deliveries.

On-Premise QAD systems are easily prone to local disruptions due to power failure, hardware failure, or even cybersecurity breaches. In most cases, internal IT teams will be quick to respond, but the recovery process itself will always involve manual intervention and longer downtimes [12]. Detailed preparations and testing of backup and recovery mechanisms at the in-house level require considerable investment in infrastructure and technical manpower.

Unreliable power or limited IT talent in the firm’s locale means that it could remain idle for months, interrupt the supply chain, or have penalties for missed deliverables on the timeline [17]. This means that, while On-Premise QAD provides more control, it also brings an increase in operational risks to maintaining uptime.

2.2.4. Upgrade Cycles

A continuous vendor-managed periodic upgrade cycle is one of the strongest advantages of cloud ERP. In the cloud platform environment, the updates to the cloud platform are released often and bring performance improvements or introduce new features or patch vulnerabilities [18]. All these upgrades are automatic, and there’s almost no involvement from internal IT [19]. This allows systems to stay current without disrupting daily business operations to an extent. More importantly, firms can deploy emerging technologies, like AI-based forecasting or machine learning analytics, without adopting a complete system change [20]. Mid-sized manufacturers can take advantage of this to achieve an agile and innovative manufacturing process without overstretching internal technical capabilities.

On the contrary, On-Premise QAD upgrades are much more complex and expensive [12]. The customization and integration within the firm make updates usually require manual intervention, revalidation, and, in numerous cases, re-customization. Upgrades can take weeks or months to be fully accomplished and are often pushed back by either cost or disruption worries. In some cases, the firms skip updating for a few years, making their systems old and less secure. This will cause new features to be delayed, as access to and with third-party applications will be impaired [3]. This means that mid-sized manufacturers using On-Premise QAD will fall behind their competitors in terms of functionality and digital maturity.

2.2.5. Scalability and Flexibility

Cloud ERP systems have unparalleled scalability and deployment flexibility. Firms can easily update user counts, storage capacity, and features as the vendor-managed portal adjusts to changing business needs [3]. This could be due to seasonal requirements, acquisitions, or geographic expansion. This elasticity would permit growth without a need for major infrastructure reinvestments [21]. In addition, it offers remote access, multi-device support, and seamless mobile integration, things that are becoming more relevant with distributed teams or hybrid work setups. The cloud platform itself allows them to adapt to changing operational needs, making it a much more future-proof solution that can grow with the organization.

On the other hand, QAD On Premise systems are not scalable at all unless more hardware, licenses, and changing configurations are added. This is especially taxing for IT rework required by scaling operations. It might be necessary to upgrade servers and delete configurations in network security just to add the users. Furthermore, geographical extension, like the presence of international subsidiaries, is a process that involves coupled integration processes with associated compatibility problems [22]. Hence, the flexibility of On-Premise QAD ERP is limited due to the physical infrastructure and technical knowledge that is available to the firm. This rigidity can hamper growth and innovation, for medium-sized firms seeking to be agile in response to opportunities in the market [21].

2.2.6. Training and Support

Subscription packages from cloud ERP vendors usually include onboarding, training resources, and ongoing customer support. In terms of services, interactive tutorials and webinars, 24/7 chat support, and account managers are the range of services provided [23]. This built-in support infrastructure makes it a much shorter learning curve and prevents adopting the system for mid-sized manufacturers who have limited internal training capability. In addition, standardized interfaces that span from the users to the devices enable better consistency in the training outcomes. With updates to cloud systems, the training modules are updated as well, providing users with the most up-to-date features and practices to offer [3].

On-Premise QAD users are typically fully supported in the compliance of its system by third-party consultants or even training teams within the organization [24]. The likely outcomes of this are total cost increase and inconsistent training. Moreover, existing training materials need to be re-created or reconfigured, as training can extend up to the times of system upgrades or changes.

Less often, cloud vendors also provide better support than firms to whom they don’t offer premium support packages [25]. Further, if internal IT teams are overwhelmed with tickets, issue resolution will become even slower. For these reasons, while On-Premise QAD can be configured to meet organizational needs, the training and support environment is prone to be more fragmented and resource-intensive.

2.3. Tools Used

2.3.1. Microsoft Excel for Modeling TCO

Modeling the Total Cost of Ownership (TCO) for both Cloud ERP and On-Premise QAD systems was prepared on Microsoft Excel. The Excel dynamic model created five-year cost scenarios for all the ERP systems. Initial capital expenditures, recurring subscription or maintenance fees, upgrade costs, training expenses, and indirect costs such as downtime were the main components of the model. The various cost elements could be structured in Excel to evaluate and compare, giving a complete picture of the financial commitment for each ERP model. The use of Excel’s built-in financial functions, such as the Net Present Value (NPV), enabled a more sophisticated comparison of the cost elements, considering the time value of money.

Excel’s visualization capabilities, including conditional formatting and data plotting, were used to ensure that the data was both accessible and interpretable. This enabled it to create graphs that brought in the cost trajectories of cloud ERP and On-Premise QAD systems very clearly. The varying cost structures were shown via line charts, and the cost differences were shown via bar graphs of the five-year projection. The ability to easily compare the overall cost implications of each ERP solution in these visual representations rendered it easy for the decision-makers to get a picture that was quite clear financially.

Applying these statistical methods made SPSS (Statistical Package for the Social Sciences) rigorous in the analysis, and the conclusions drawn from the survey response were meaningful. That is, the combination of descriptive and inferential statistics provided a clear picture of how the stakeholders viewed the two ERP systems. In that context, the use of SPSS allowed me to confirm trends identified in qualitative data to establish recommendations. The survey itself was made more credible because it had statistical evidence to support the conclusions that were drawn from the survey.

2.3.2. SPSS for Statistical Analysis

The SPSS software tool was used to analyze the statistical information that was collected from IT managers and financial officers and helped to quantify the value and satisfaction perceptions of the implemented ERP systems. Descriptive statistics of standard deviations and means were calculated to present summaries of respondents’ general attitude and experience concerning Cloud ERP and On-Premise QAD systems. The univariate statistics gave a clear indication of the responses’ central tendencies and presented a very valuable insight into overall levels of satisfaction for both ERP deployment techniques [26]. This was the first step in data interpretation and the identification of any significant patterns.

To comprehend the relationships among various variables, inferential statistical methods were employed via SPSS. Paired t-tests were performed wherein the means of perceived value and satisfaction in the two ERP systems were compared. This enabled a conclusion of whether differences in perceptions were statistically significant, to further support or refute assumptions based on preliminary survey results [27]. Analysis of Variance (ANOVA) was also performed to test for significant differences in perceptions by organizational size or by role of respondent. The tests enabled a deeper statistical comprehension of the data.

With the application of these statistical methods, SPSS brought rigor to the analysis such that conclusions could be meaningfully drawn from the survey responses. Inferential and descriptive statistics helped to give a clear indication of the stakeholders’ perception of the two ERP systems. The application of SPSS in the case helped in the validation of trends evident from the qualitative data and justified the formulation of recommendations [26]. SPSS helped in enabling the conclusions made from the survey to be buttressed with statistical evidence, lending authenticity to the study findings.

2.3.3. Python for Statistical Analysis

A powerful tool used for statistical analysis was Python, and this was especially true when working with large datasets and complex visualizations was necessary. I used libraries such as Pandas and NumPy to process the data; many of these files were then cleaned, organized, and summarized to respond to survey questions. This flexibility of Python allowed easy manipulation of the data that was necessary to find the key trends and patterns represented in the responses. To effectively perform the mining of the raw data, it was necessary to have the ability to quickly do data aggregation and filtering [28]. This sped up the process to pinpoint meaningful patterns and trends that could be derived.

Like what is done in SPSS, the tests of inferential statistical analysis were done using Python’s SciPy library. The use of these statistical methods enabled us to determine whether there were significant differences in the perceptions of the Cloud ERP and On-Premise QAD systems concerning different factors. Running these tests, I was able to point out statistically significant differences in the levels of satisfaction given by the various respondent groups. Based on the outputs, the factors influencing perceptions were then interpreted better to enable data-driven comparison of ERP solutions.

Additionally, the statistical results were presented in a compelling visual representation using Python’s data visualization capabilities using Matplotlib and Seaborn. A simple illustration of the distribution of survey responses from bar graphs, histograms, and box plots was provided to easily identify trends and anomalies. The statistical analysis was complemented by these visualizations, which made the data more intuitive. The fact that the survey data can be analyzed for its statistics and accordingly visualized is where Python is the bluestocking; it made it a first-class tool for producing comprehensive, actionable insights [28].

3. Results and Diagram

3.1. Cost Analysis

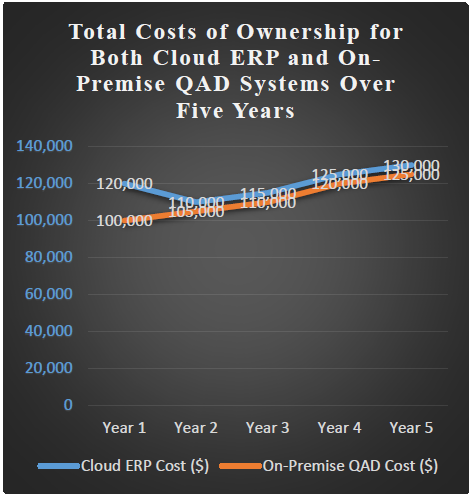

The yearly projected costs for both Cloud ERP and On-Premise QAD systems are formulated as shown in Table 4 and the linear graph denoted in Figure 3. Year 1, On-Premise QAD has the benefit of lower costs by incurring a total of $100,000 compared to Cloud ERP’s $120,000. Much of this can be accounted for by the high initial cost of cloud ERP in terms of licensing, integration, and integration of users. On the other hand, On-Premise QAD, although hardware purchase-intensive in the classical sense, is aided by existing infrastructure and deployment practices that are easier to manage.

Table 4: Total Costs of Both Cloud ERP and On-Premise QAD Systems Over Five Years

Year | Cloud ERP Cost ($) | On-Premise QAD Cost ($) |

Year 1 | 120,000 | 100,000 |

Year 2 | 110,000 | 105,000 |

Year 3 | 115,000 | 110,000 |

Year 4 | 125,000 | 120,000 |

Year 5 | 130,000 | 125,000 |

Let us, however, keep in mind that the On-Premise method entails a one-time bulk payment, whereas cloud ERP is in a subscription mode [24]. Cloud ERP then turns out to be the more cash-flow-friendly option among firms desirous of having the costs spread. Even in the presence of higher Year 1 costs, many mid-size firms prefer cloud ERP due to ease of operation and abbreviated implementation cycle in the case of suboptimal in-house IT infrastructure.

As of Year 2, Cloud ERP drops to $110,000 because of reduced implementation-related fees and standardized rates of subscription and servicing. On the other hand, On-Premise QAD increases to $105,000 because of early-stage servicing, patch management, and IT overhead staff. During the second phase, the flexibility of Cloud ERP begins delivering value. Update and patch management are done by the vendor, leaving internal teams free to focus on the business and not IT administration [3]. While both the systems stabilize in operational spending, the variation in the composition of the respective supports and system uptime reliability begins to become evident. Cloud ERP has a propensity to display higher compliance to the service-level agreements (SLAs) that prevent potential hidden costs of downtime from surfacing in an upfront form in the table but affect productivity and ROI in the long term. As both ERP solutions reach the mature phase, both their spending paths converge.

Cloud ERP in Year 3 is at $115,000, and On-Premise QAD is at $110,000, still increasing because of infrastructure depreciation and increasing requirements for maintenance. Cloud ERP reaches $125,000 by Year 4, whereas On-Premise QAD narrows the gap to $120,000. Midsized manufacturers can now see the long-term benefit of automation, real-time analysis, and multi-device access that cloud ERP provides. On-Premise QAD, nevertheless, can mean astronomical manual upgrades in addition to renegotiation of licensing, thus making the typical surge in spending very difficult to project [24]. On-Premise solutions also tend to involve routine hardware refresh cycles, increasing the TCO. Add to that the financial as well as operational stability that Cloud ERP provides in the first two years of deployment.

By Year 5, the two options are in near parity, with Cloud ERP at a price tag of $130,000 and On-Premise QAD at a price tag of $125,000. While the numerical distance closes, the intangible advantages of cloud ERP—less IT overhead, easier scalability, and vendor-hosted development—deliver increasing ROI. Growth digital strategy firms are drawn to reduced complexity and integration ease with other cloud solutions [29]. The firms that need special security or compliance features, however, are still drawn to On-Premise QAD even with the added constant IT support expense.

The five-year cumulative price is so little in Cloud ERP’s favor when considering reduced downtime and time in upgrades. Decision-makers, ultimately, view the trend as verification that even when On-Premise QAD is cheaper in the short term, cloud ERP is better positioned for strategic and fiscal flexibility in the longer term [30].

3.2. Benefits Evaluation

Cloud-based ERP technology provides tremendous increases in productivity from the automation of routine tasks and end-to-end process integration by the department. Through the centralized availability of information and ease of use of the dashboards, employees can spend less time performing manual data entry and more time performing strategic tasks. Cloud technology also ensures that updates and enhancements are done seamlessly, maximizing the productivity of users [3].

On the other hand, On-Premise QAD means more manual configuration and less quick responsiveness to process changes. Cloud ERP’s flexibility naturally translates to higher productivity, especially in mid-sized companies where manpower can be tight [31]. Furthermore, processes in the cloud solution are configurable with fewer IT assets, reducing the need for technical resources and increasing operational agility.

User satisfaction increases due to ease of use, availability from a wide range of devices, and reduced in-house IT service requests. Users benefit from reduced downtime, uninterrupted upgrades, and consistent system performance [32]. End-users as well as IT managers both indicated that cloud ERP interfaces were more user-friendly, particularly for IT-savvy, young workers. On the other hand, On-Premise QAD users reportedly had a higher learning curve and an increased technical support demand. Response times to correct technical difficulties also had an impact that contributed to the level of satisfaction, with faster responses from the vendors in the cloud compared to in-house companies [19]. One of the most important things that firms with few technical resources should be aware of.

Another area Cloud ERP leads in is time to deployment. Most deployments in the cloud happen in a fraction of the time, sometimes weeks, compared to installing and configuring On-Premise based QAD, which takes several months. Time of deployment is a byproduct of the cloud’s standardized infrastructure, as the installation of hardware and heavy customizations are bypassed. For mid-size manufacturers wanting to feel the impact of digital transformation in a short period, that’s a big advantage [1]. Saved time in implementation equates to them returning to core operations as quickly as possible and seeing a faster return on investment [8]. On-Premise based environments, on the other hand, demand careful planning, resources, and time-consuming testing before mass rollout, keeping the benefits in check.

3.3. Risk and Security Concerns

Risk continues to be a primary concern over ERP systems, and each of the deployment options offers a different type of risk. Cloud ERP, under its web-based platform, is most likely, in the eyes of most, to be subject to cyberattack [33]. Most vendors of cloud, however, implement stringent security measures, such as encryption, multi-factor authentication, and regular audits. Despite that, companies with very confidential data may still be apprehensive, desiring to maintain security in their control in-house.

On-Premise QAD applications, although offering greater control now, are no risk-free option either. They necessarily depend on the internal IT organization’s efforts to keep patching and defenses current; in mid-size companies with limited resources, it is too often a difficult task [2].

Data sovereignty and regulation compliance also play a role in the decision to deploy. Cloud ERP vendors keep their data centers in numerous jurisdictions, raising the question of where the company data resides and under what regulations [34]. A special concern to manufacturers in the most heavily regulated industries, such as pharmaceutical or defense, On-Premise QAD gives the company greater control over where the data resides, simplifying compliance with local regulations. Compliance, however, is solely the company’s responsibility and may involve heavy internal monitoring. A study found that companies that had internal teams of lawyers and IT compliance experts felt comfortable with On-Premise environments.

Business Continuity and Disaster Recovery is another risk. Cloud ERP provides greater disaster recovery through automatically established backups and failover capability [35]. These are embedded in the service and tested routinely, offering security for companies. On-Premise deployments of QAD require companies to implement and maintain recovery provisions, which may be costly as well as complex. Midsized companies with tight IT budgets may find this a task and therefore value the convenience of the cloud. Some companies value the control and flexibility of On-Premise disaster recovery planning, however.

Table 5: Comparative Table for Qualitative and Quantitative Metrics.

Metric | Cloud ERP | On-Premise QAD |

Initial Investment | Lower (subscription model) | Higher (hardware + license) |

Maintenance Costs | Vendor-handled, predictable | In-house, variable |

Deployment Time | Weeks | Months |

Downtime Risk | Lower (vendor-managed) | Higher (in-house dependent) |

Scalability | High (elastic infrastructure) | Limited (requires upgrades) |

Training Requirement | Moderate | High |

User Satisfaction | Higher | Moderate |

Security Control | Vendor-managed, standardized | Direct, customizable |

Regulatory Compliance | Vendor-dependent | In-house controlled |

Disaster Recovery | Automated and integrated | Manual and resource-intensive |

Table 5 shows qualitative and quantitative comparison of ERP metrics and points out the respective strengths and limitations of cloud ERP and On-Premise QAD solutions. Cloud ERP is far superior in less initial investment, faster deployment time, and reduced risk of downtime—characteristics well aligned to the needs of medium-sized enterprises seeking agility and cost benefits. It also provides more scalability and enhanced user satisfaction, thanks to its vendor-managed model and modern interfaces [7].

Conversely, On-Premise QAD excels in areas that require direct control, i.e., security tailoring and compliance with regulations, and is hence suited for companies in highly regulated industries. However, it involves more investment, more training, and internal resources for disaster recovery and upkeep [35]. This comparative approach is a concise, strategic comparison that enables decision-makers to select the most appropriate ERP solution to meet their operational requirements and capabilities.

3.4. Discussion

The study shows Cloud ERP leads in time-to-deployment, long-term maintenance, user satisfaction, and scalability. Its pay-as-you-go model reduces the initial purchase price and keeps the companies continuously updated without the price of upgrades. The scalability of the resources in response to the needs of the company is most attractive to growing mid-size manufacturers [21]. Cloud solutions also encompass built-in disaster recovery and remote access that accommodate the new realities in the workforce. These benefits make cloud ERP a strategic investment option for companies adopting agility and long-term digital strategies [36].

Conversely, On-Premise solutions continue to be attractive to companies that prefer to maintain control of their IT infrastructure. On-Premise solutions will find growth among companies in heavily governed industries or companies with complex, specialized processes, where customizability will be worth more than the advantage of fast deployment [2]. Some mid-size manufacturers that possess good in-house IT capabilities will prefer On-Premise QAD so that they can maintain internal compliance and governance control. Although it is harder to set up and maintain, it provides a tailored solution that can closely match operational requirements [37].

Together, both ERP approaches involve trade-offs. Cloud ERP is more appropriate for firms seeking growth and possessing constrained IT resources [34]. On-Premise QAD is best for firms that are concerned about control and are ready to invest in in-house infrastructure. Leaders need to find a sense of balance regarding cost, compliance, and scalability with the current readiness and strategic direction of the company [7]. Only this balanced strategy will find the investment in ERP serving the cause of sustainable business results instead of short-term operational remedies.

3.5. Alignment with Existing Literature

The research confirms prevailing trends in previous ERP studies. Initial studies, including the work done by Gartner and Forrester, had indicated increasing adoption of cloud-based ERP solutions by mid-size enterprises due to reduced overall cost of ownership and faster deployment. These claims are borne out by our study, with ease of maintainability and customer satisfaction as the major benefits. These observations concord with prevailing industry reports of the trend of adoption of Software-As-A-Service (SaaS) offerings in the enterprise resource planning space [31].

However, they also challenge some of the assumptions in literature. As an example, whereas the overall assumption is that low-cost cloud ERP options are available, our study implies that, in the long run at the very least, the costs are likely to be roughly equal if subscription costs rise. Further, the regulatory and data sovereignty problems of the cloud ERP are minimized. These are seen by our study as genuine impediments to adoption by some firms, and the study has implications for more industry-specific, targeted advice.

Lastly, the mapping of ERP model selection to firm size and digital maturity is an issue to which this research contributes fresh knowledge. Though other research has collapsed medium-size companies into one category, findings from their present research indicate that even within this category, variations in strategic intent and access to resources significantly shape ERP preferences [38]. The findings imply the necessity for ERP guidance that will be customized according to more specific firm traits other than wide categories.

3.6. Contextualization for Mid-Sized Companies

Medium-sized manufacturers are likely to be constrained by budget limitations that influence how they invest in IT. In contrast to large companies with unlimited budgets, such companies need to balance the cost to justify the function [39]. Cloud ERP’s subscription model provides a pay-as-you-go option that enables the bypassing of huge upfront capital expenditures, making it affordable. Affordability, along with reduced maintenance, strongly attracts companies that are under strict budget controls. Without the necessity to invest in costly hardware and reduce the requirement for in-house IT experts, companies can invest in core manufacturing processes while still developing digital infrastructure [1].

In-house IT limitations are also a hindrance to mid-sized manufacturers. Most of them maintain skeleton IT departments, and dealing with costly, complicated in-house-based systems is a difficult task [40]. Cloud-based vendor-managed ERP minimizes this by doing most of the technical heavy lifting, including updates, maintenance, and security. This frees the in-house team to apply their efforts to strategic projects rather than constantly putting out fires. The ease of deployment and vendor-provided training also facilitate end-user adoption faster, so the company can leverage the value of the technology without the overhead of creating extensive IT capabilities.

Mid-size company strategic planning is all about growth plans [21]. These companies look for solutions that can grow with them as they move into new markets or new product lines. Cloud ERP elasticity provides the scalability by number of users, by storage, or by new requirements for new modules—without the need to resize infrastructure. Scaling On-Premise for QAD, in contrast, presents physical upgrades and re-architecture that can be both costly and disruptive [32]. For visionary mid-size companies, having that flexibility is the solution to maintaining momentum without undergoing repeated technological reinventions.

4. Conclusion

4.1. Key Findings and Strategic Implications

This study offers a comparative analysis of Cloud ERP and On-Premise QAD ERP solutions designed for mid-sized manufacturers. The results indicate that Cloud ERP has distinct advantages, including diminished initial capital expenditure, expedited implementation, decreased internal IT workload, and improved scalability. These advantages result in sustained operational efficiency and agility, especially for organizations seeking rapid expansion and digital transformation [5].

Conversely, On-Premise QAD ERP remains advantageous for companies in sectors with stringent regulatory standards, sensitive data handling, and intricate customization needs. Despite requiring higher initial investment and continuous maintenance, it provides enhanced system control and customization options [3].

Consequently, ERP deployment should not be perceived as a uniform solution applicable to all scenarios. Strategic alignment with business size, digital maturity, compliance framework, and growth trajectory is crucial for determining the optimal ERP deployment option.

4.2. Contribution to ERP Decision-Making Practice

This study addresses a deficiency in ERP literature by focusing on the distinct problems and decision-making requirements of mid-sized manufacturing enterprises. The report provides a comprehensive methodology for ERP evaluation by integrating quantitative total cost of ownership modeling, qualitative stakeholder interviews, and third-party standards. It facilitates educated, contextual, and evidence-based decisions on ERP investments [9].

This study significantly contributes to the literature by transcending conventional ERP adoption tales and offering focused insights into a critically under-explored yet strategically essential sector: mid-sized manufacturing. This study specifically examines the decision-making processes of resource-constrained organizations seeking digital competitiveness, in contrast to larger ERP research that targets large enterprises or generalizes across various firm sizes. It substantiates its conclusions through meticulous data analysis and aligns them with the dynamic requirements of the industry, including agility, hybrid infrastructure models, and expedited deployment expectations [29].

This research enhances its practical applicability by providing both qualitative and quantitative analysis derived from real-world case data across several industries, thereby circumventing the shortcomings of anecdotal generalization. This accords with modern ERP literature’s calls for domain-specific, empirically grounded studies that capture the intricacies of mid-sized company environments. This paper enhances the discussion on ERP adoption by presenting a comprehensive decision-support framework that connects theoretical models with practical applications.

Executives in mid-sized enterprises can utilize the comparison approach presented here to synchronize ERP strategy with overarching operational objectives, IT capabilities, and fiscal limitations. The study underscores the significance of perceiving ERP not merely as a technology enhancement, but as a strategic facilitator of agility, competitiveness, and digital preparedness.

4.3. Recommendations

Cloud ERP is advisable for mid-sized enterprises with constrained internal IT capabilities, a requirement for scalability, and a desire for swift digital transformation [41]. Industries such as consumer goods, logistics, and electronics can benefit significantly from the lower operational overhead and higher agility [19]. On-Premise QAD ERP is better suited to organizations in highly regulated sectors such as pharmaceuticals, defense, and aerospace where data sovereignty, compliance, and deep customization are critical [10]. A hybrid ERP approach may be ideal for organizations with diverse operational requirements, enabling them to retain critical workloads On-Premise while utilizing cloud-based modules for enhanced agility and innovation.

4.4. Future Research

The paper goes past anecdotal comparisons and presents an evidence-based, step-by-step methodology to use in evaluating ERP in medium-sized manufacturing settings. It enhances the analytical soundness of ERP trade-off analysis by integrating both qualitative, cost models and infrastructure benchmarks. Primary data and secondary benchmarking used in support of QAD ERP has ensured that findings record reality. This will change the study into a descriptive account of a strategic ERP decision-making resource. The rapid digitization of mid-sized firms is challenging the effectiveness of ERP deployment strategies regarding resource resourcefulness and expansion goals; hence the prescribed study provides a repeatable methodological strategy on how such firms on a limited budget and international ambitions can align business goals with resource potentialities [9].

Future study should investigate industry-specific ERP adoption to examine the performance of ERP systems under diverse regulatory and operational demands. Furthermore, longitudinal studies evaluating ERP effectiveness and ROI beyond the initial five-year period would yield insights regarding the long-term durability of the system [8]. Tracking performance, cost, user satisfaction, and operational flexibility over several years would provide data on the actual return on investment and flexibility of each system [42].

It is essential to investigate the integration of ERP systems with emerging technologies, like AI, IoT, and blockchain. Comprehending these interconnections can provide anticipatory insights for ERP planning in Industry 4.0 contexts [20]. As ERP ecosystems develop, continuous research must adapt to monitor changes in cost structures, user expectations, and technological advancements.

- A. R. Mudiraj, ERP Systems Implementation in Manufacturing: An Analytical Approach, Notion Press, 2024.

- L. Emma, “Enterprise Resource Planning (ERP) Systems for Streamlining Organizational Processes,” 2024. [Online]. Available: https://www.researchgate.net/publication/386382658

- A. Maurushat and K. Nguyen, “The legal obligation to provide timely security patching and automatic updates,” International Cybersecurity Law Review, vol. 3, no. 2, 2022, doi: 10.1365/s43439-022-00059-6.

- M. Odesanya and G. Odigie, “The impact of business analytics on global financial performance and economic contribution of small and mid-sized enterprises,” World Journal of Advanced Research and Reviews, vol. 16, no. 3, pp. 1158–1180, Dec. 2022, doi: 10.30574/wjarr.2022.16.3.1224.

- T. Cristofaro, “Kube: a cloud ERP system based on microservices and serverless architecture,” (Master’s Thesis, Politecnico Di Torino, 2022).

- S. Sharpe, J-F. Mercure, J. Vinuales, M. Ives, M. Grubb, H. Pollitt, F. Knobloch, and F.J.M.M. Nijsse (2021), “Deciding how to decide: Risk-opportunity analysis as a generalisation of cost-benefit analysis,” UCL Institute for Innovation and Public Purpose, Working Paper Series (IIPP WP 2021/03).

- N. Coviello, E. Autio, S. Nambisan, H. Patzelt, and L. D. W. Thomas, “Organizational scaling, scalability, and scale-up: Definitional harmonization and a research agenda,” Journal of Business Venturing, vol. 39, no. 5, p. 106419, Sep. 2024, doi: 10.1016/J.JBUSVENT.2024.106419.

- M. Mestica, “Small- to Medium-Sized Business ERP Implementation,” (Master’s Thesis, Haaga-Helia University of Applied Sciences, 2024).

- K. Nanath and R. Pillai, “A Model for Cost-Benefit Analysis of Cloud Computing,” Journal of International Technology and Information Management, vol. 22, no. 3, 2013, doi: 10.58729/1941-6679.1017.

- B. Li and S. Kumar, “Managing Software-as-a-Service: Pricing and operations,” Production and Operations Management, vol. 31, no. 6, 2022, doi: 10.1111/poms.13729.

- H. Boukeffa and Z. Hambli, “The implementation of ERP systems in manufacturing firms:, Its merits, prerequisites and impact on business performance of local firms,” مجلة الدراسات المالية والمحاسبية والإدارية, p. 236, Jan. 2022, doi: 10.35392/1772-009-002-014.

- A. Kalra and Y. Moukhtar, “Comparative Analysis of On-Premises and Cloud Hosting Solutions”, Dissertation, 2024.

- R. K. Arora, A. Kumar, A. Soni, and A. Tiwari, “AI-Driven Self-Healing Cloud Systems: Enhancing Reliability and Reducing Downtime through Event-Driven Automation,” Soft Computing Research Society, 2024, pp. 293–301. doi: 10.56155/978-81-955020-9-7-28.

- M. E. Husain, I. Hussain, S. Tanweer, and I. R. Khan, “Transitioning from data centers to cloud: An in-depth analysis of Microsoft SQL Server’s role in DBaaS and on-premise solutions,” International Conference on Information Management & Machine Intelligence, pp 1-9, 2023, doi: 10.1145/3647444.3652491

- J. Pousi, “Migration from on-premise to public cloud — Case: Migrating a service of Finnish governmental organization from on-premise to public cloud,” (Master’s Thesis, Aalto University School of Science, 2024).

- S. Shrestha, “Exploring New Revenue Streams in a Software Company,” (Master’s Thesis, Metropolia University of Applied Sciences, 2023).

- J. Yang, H. Xie, G. Yu, and M. Liu, “Achieving a just–in–time supply chain: The role of supply chain intelligence,” International Journal of Production Economics, vol. 231, p. 107878, Jul. 2020, doi: 10.1016/j.ijpe.2020.107878.

- F. Jimmy, “Cyber security Vulnerabilities and Remediation Through Cloud Security Tools,” Journal of Artificial Intelligence General Science (JAIGS), vol. 2, no. 1, pp. 129–171, Apr. 2024, doi: 10.60087/jaigs.v2i1.102.

- R. Guo, A. Tafti, and R. Subramanyam, “Internal IT modularity, firm size, and adoption of cloud computing,” Electronic Commerce Research, Apr. 2023, doi: 10.1007/s10660-023-09691-8.

- N. Rane, M. Paramesha, S. Choudhary and J. Rane, “Artificial Intelligence, Machine Learning, and Deep Learning for Advanced Business Strategies: A Review”, Partners Universal International Innovation Journal (PUIIJ), vol. 2, no. 3, pp. 147–171, Jun. 2024, doi: 10.5281/zenodo.12208298.

- G. Wolbers and A. K. Pillutla, “Mid-size firm growth: The process and empirical examination of key drivers,” International Small Business Journal Researching Entrepreneurship, vol. 40, no. 6, pp. 710–741, Sep. 2022, doi: 10.1177/02662426221097385.

- R. Belderbos, D. Castellani, H. S. Du, and G. H. Lee, “Internal versus external agglomeration advantages in investment location choice: The role of global cities’ international connectivity,” Journal of International Business Studies, vol. 55, no. 6, pp. 745–763, Mar. 2024, doi: 10.1057/s41267-024-00686-7.

- M. Ng, N. Chamileke, V. Mapulanga, N. Campain, and S. Payne, “The benefits of virtual learning webinars to both low‐ and high‐income countries,” BJU International, vol. 129, no. 4, pp. 434–441, Feb. 2022, doi: 10.1111/bju.15705.

- Y. Guo, “Transformation from On-Premise Software to Cloud Computing-Based Services: A Case Study of SAP Practices,” (Ph. D Thesis, The University of Manchester, 2021).

- G. Mott et al., “Between a rock and a hard(ening) place: Cyber insurance in the ransomware era,” Computers & Security, vol. 128, p. 103162, Feb. 2023, doi: 10.1016/j.cose.2023.103162.

- M. Barha, S. Hmimou, M. A. Kerroum, and H. A. Lemqeddem, “The internal reliability of a questionnaire on the impact of enterprise resource planning on the performance of Moroccan companies,” Advances in Science Technology and Engineering Systems Journal, vol. 6, no. 5, pp. 59–64, Sep. 2021, doi: 10.25046/aj060508.

- S. M. Roni and H. G. Djajadikerta, “Data Analysis with SPSS for Survey-based Research,” Springer Singapore, 2021. doi: 10.1007/978-981-16-0193-4.

- J. Peng, W. Wu, B. Lockhart, S. Bian, J. N. Yan, L. Xu, Z. Chi, J. M. Rzeszotarski & J. Wang, “DataPrEP.EDA: Task-Centric Exploratory Data Analysis for statistical modeling in Python,” Proceedings of the 2022 International Conference on Management of Data, pp. 2271–2280, Jun. 2021, doi: 10.1145/3448016.3457330.

- H. W. Volberda, S. Khanagha, C. Baden-Fuller, O. R. Mihalache, and J. Birkinshaw, “Strategizing in a digital world: Overcoming cognitive barriers, reconfiguring routines and introducing new organizational forms,” Long Range Planning, vol. 54, no. 5, p. 102110, May 2021, doi: 10.1016/j.lrp.2021.102110.

- D. Dwivedi, “A Survey on Enterprise Resource Planning in the Cloud Era Based on Current Trends and Future Directions,” International Journal of Current Engineering and Technology, vol. 14, no. 6, doi: 10.14741/ijcet/v.14.6.8.

- S. Sarferaz, “Compendium on Enterprise Resource Planning,” Springer, 2022, doi: 10.1007/978-3-030-93856-7.

- Y. Zhang, J. Yang, Z. Jin, U. Sethi, K. Rodrigues, S. Lu & D. Yuan, “Understanding and Detecting Software Upgrade Failures in Distributed Systems,” Proceedings of the ACM SIGOPS 28th Symposium on Operating Systems Principles, pp. 116-131, 2021, doi:10.1145/3477132.3483577.

- E. N. Gethrude, “An end-user centred framework for data access management and security in the enterprise public cloud.,” (Ph. D Thesis, University of Strathclyde, 2024).

- V. Paulsson and B. Johansson, “Cloud ERP systems architectural challenges on cloud adoption in large international organizations: A sociomaterial perspective,” Procedia Computer Science, vol. 219, pp. 797–806, Jan. 2023, doi: 10.1016/j.procs.2023.01.353.

- S. Tatineni, “Cloud-Based Business Continuity and Disaster Recovery Strategies,” International Research Journal of Modernization in Engineering Technology and Science, Nov. 2023, doi: 10.56726/irjmets46236.

- P. Morawiec and A. Sołtysik-Piorunkiewicz, “ERP System Development for Business Agility in Industry 4.0—A literature Review based on the TOE Framework,” Sustainability, vol. 15, no. 5, p. 4646, Mar. 2023, doi: 10.3390/su15054646.

- F. Farajirad, “Transitioning Data from an On-Premise Solution to a Cloud-Based Platform,” (Master’s Thesis, University of South-Eastern Norway, 2024)

- I. Steinerowska-Streb, G. Glod, and A. Steiner, “What do we know about small and medium enterprises’ survival in a post-global economic crisis context?,” Local Economy the Journal of the Local Economy Policy Unit, vol. 37, no. 4, pp. 259–278, Jun. 2022, doi: 10.1177/02690942221112042.

- M. Nakash and D. Bouhnik, “Challenges of justification of investment in organizational knowledge management,” Knowledge Management Research & Practice, vol. 21, no. 4, pp. 703–713, Nov. 2021, doi: 10.1080/14778238.2021.1999184.

- W. Xu, T. Fujimoto, and Z. Fan, “Problems with the corporate information system for work efficiency improvement,” in Proc. 27th Int. Conf. on Systems Engineering (ICSEng 2020), H. Selvaraj, G. Chmaj, and D. Zydek, Eds. Cham, Switzerland: Springer, 2021, vol. 182, Lecture Notes in Networks and Systems, pp. 277–286, doi: 10.1007/978-3-030-65796-3_26.

- F. O. Ugbebor, “Intelligent cloud solutions bridging technology gaps for Small and Medium-Sized Enterprises,” Journal of Artificial Intelligence General Science (JAIGS), vol. 7, no. 01, pp. 161–186, Jan. 2025, doi: 10.60087/jaigs.v7i01.307.

- H. Siagian, Z. J. H. Tarigan, and F. Jie, “Supply chain integration enables resilience, flexibility, and innovation to improve business performance in COVID-19 era,” Sustainability, vol. 13, no. 9, p. 4669, Apr. 2021, doi: 10.3390/su13094669.