Analyzing the Impact of Challenges in Prefabricated Building Construction Supply Chains

Journal of Engineering Research and Sciences, Volume 1, Issue 5, Page # 71-78, 2022; DOI: 10.55708/js0105008

Keywords: Supply Chain Challenges, Prefabricated Construction, Relative Impact, Relationship Matrix

(This article belongs to the Section Construction and Building Technology (CBT))

Export Citations

Cite

Rastogi, R. , Solanki, S. K. and Paul, V. K. (2022). Analyzing the Impact of Challenges in Prefabricated Building Construction Supply Chains. Journal of Engineering Research and Sciences, 1(5), 71–78. https://doi.org/10.55708/js0105008

Rishabh Rastogi, Sushil Kumar Solanki and Virendra Kumar Paul. "Analyzing the Impact of Challenges in Prefabricated Building Construction Supply Chains." Journal of Engineering Research and Sciences 1, no. 5 (May 2022): 71–78. https://doi.org/10.55708/js0105008

R. Rastogi, S.K. Solanki and V.K. Paul, "Analyzing the Impact of Challenges in Prefabricated Building Construction Supply Chains," Journal of Engineering Research and Sciences, vol. 1, no. 5, pp. 71–78, May. 2022, doi: 10.55708/js0105008.

Across various barriers pertaining to prefabricated building construction projects, a major barrier identified by the literature was integration of various components of prefabricated building project supply chain network, including the material and human resource supply chains. The literature suggests a need of exploring this barrier of supply chain integration into its various sub factors/challenges (termed as supply chain challenges) with the perspective of prefabricated building construction supply chains. This research tries to fill this gap by analyzing three cases of existing prefabricated building construction supply chains in Indian context with different configurations, geophysical profiles and project typologies. This study gives an understanding of the relationship among supply chain challenges, the variation in their relative impact on project time and cost (within the supply chain and across the different configurations of supply chains), and the underlying causes of these variations.

1. Introduction

The integration of supply chain management in the construction industry is a relatively new concept in India, which has attracted the attention of professionals in recent few years. Various theories and models of supply chain and its management from the vast knowledge pool of industrial/manufacturing supply chains have been adopted and have been implemented in the construction industry. However, the effectiveness and benefits of implementing these models for a successful management of construction supply chains is questionable. This is because, unlike the sequential and mostly linear manufacturing supply chains, the construction supply chains are rather more complex [1], comprising of activities and multiple acting parties which involve various other types of interdependencies apart from the traditional sequential/linear dependency. Also, construction supply chains are unique with respect to the project in consideration which, in a generalized way can be broadly classified into two major categories of supply chains, a) The material and equipment supply chains and; b) The human resource supply chains [2] ; which formulate the three dimensions of a supply chain in a project namely; design dimension, demand dimension and supply dimension. Efficiency of supply chain as a whole is dependent upon individual performance as well as the integration among these dimensions.

These supply chain fundamentals apply to the realm of prefabricated building construction as well, however the uniqueness of this typology of construction is that it comprises of a traditional sequential manufacturing supply chain (for prefabricated building component manufacture and supply) as a very significant component in the material and equipment supply chain network of the project [3]. An established prefabricated building component supply chain consists of a stable and consistent manufacturing process and has low uncertainties associated with it for a specific construction project [4]. This stability promotes the adoption of supply chain management principles of “Lean thinking” and “Just in Time Production” to improve its efficiency. However, the integration of these supply chain principles and models with the overall network of supply chains in a construction project raises its own challenges in terms of management and optimization of project schedule and cost (as the high levels of uncertainties in construction project favors agile principles instead of lean principles) [3].

Literature on prefabricated construction suggests that most of the barriers in prefabricated building construction are multi stakeholder in nature and are influenced by various entities throughout the manufacture, construction and design dimensions of a prefabricated construction project [2]-[6] and can be broadly classified into following six factors,

Table 1: Barriers of Prefabricated Building Construction

Factor 1: Industry Chain | Factor 4: Construction Implementation |

Factor 2: Cost Parameters | Factor 5: Architectural Performance |

Factor 3: Social Climate and Public Opinion | Factor 6: External Conditions |

Source: [7]-[11]

According to literature, major hindrances in implementation of prefabricated construction were in factors of – “Industry Chain”, “Cost Parameters” and “Construction Implementation” [6]-[8], [10], [12]. Industry experts in India also identified that nature of planning system and fragmented industry are among the major barriers for prefabricated construction in India [9]. The multi-stakeholder characteristic of barriers of prefabricated construction demands an analysis at industry chain and supply chain levels, to identify the root causes of multi-dimensional supply chain challenges of prefabricated construction projects in India [1].

This paper attempts at bridging the gap by analyzing the impact of various challenges pertaining to the prefabricated building supply chains; using relative impact tables and relationship matrix and diagrams. The data obtained for this study is through structured interviews and discussions with industry professionals of considered supply chain cases in Indian context.

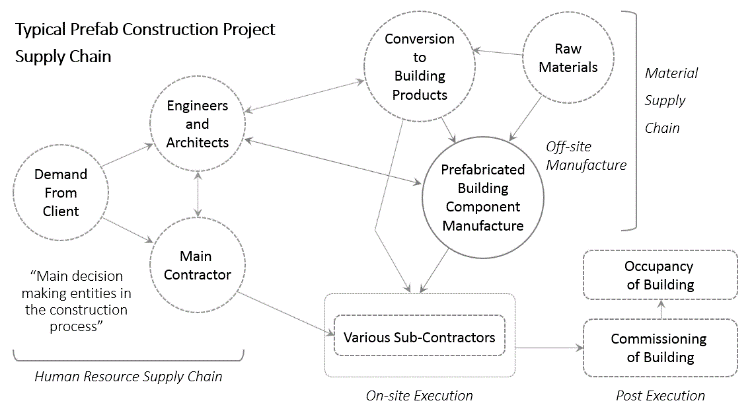

2. Prefabricated Building Construction Supply Chains

A prefabricated building project essentially comprises of two different material supply chains, including raw material supply chain (Type-1) such as that of cement, aggregate, sand, infill wall blocks (AAC blocks / bricks / cement blocks / CLC blocks), etc. These materials are required on a continuous basis and are ordered in bulk for in-situ works for walling, casting of foundation, unique building elements and high tensile grouting for the prefabricated component assembly, etc. The ordering strategy of these materials is variable and follows the principle of make-to-stock, as their utilization rate changes throughout the construction schedule (as per the sequence of construction activities) of a prefabricated construction project.

The second kind of material supply chain for a prefabricated construction project is that of precast components, manufactured on-site or off-site (Type-2). These include the precast structural components such as, beams, columns, slabs, shear walls, infill wall panels, etc. These components are unique for every construction project, with respect to their size, shape and joinery between various components. The components are quantified in exact numbers as per the building plans and details; hence, the ordering strategy for such building material components is highly specific and follows the principle of make-to-order [13]. As these components are termed as highly essential and critical as per construction schedule and their supply is dependent on a third agency associated to the construction process (the supplier), thus, their ordering schedules are well monitored and controlled to mitigate any deviation from the planned construction schedule.

The third supply chain comprises of human resource, such as the designers / architects, engineers, project managers, etc. These are the primary decision making bodies for a construction project. Engineers and architects are responsible for defining and providing various details for prefabricated components to the manufacturer. Project managers are responsible for determining the construction schedule, which governs the ordering schedule of various materials including order of prefab components from the manufacturer. Hence, it becomes essential for the manufacturer to receive information from both sources (designers and site supervisors) to process the production of required component as per the details and its supply as per the provided schedule [14], [15]. Coordination between these three entities is essential for a successful supply of correct building component with minimal processing / waiting time and achieving low lead times.

Source: Adapted from typical construction project supply chain by [16]

3. Supply Chain Configuration

Data for the configuration of considered cases of supply chain in India was carried out using structured interviews and discussions with the industry professionals. Details are presented as appendix.

4. Relative Impact of Supply Chain Challenges

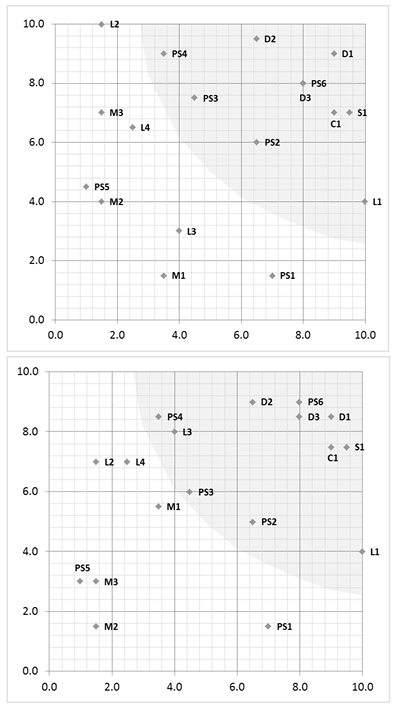

Structured interviews were conducted with the suppliers to identify and score the likelihood of occurrence, relative impact on project time and cost for various supply chain challenges. This data was collected by interviewing 3-4 responders from their respective supply chains. As the responses from these responders were specific, pertaining to a single supply chain, the mean values of these responses was considered for each respective supply chain. This data was then analyzed using the likelihood vs. relative impact graph, to identify critical challenges.

5. Identification of Critical Challenges

The plotted graphs of likelihood of occurrence vs relative time / cost impact represent that the challenges that are most critical with respect to the supply chain in Case-1 are presented in table 2.

Table 2: Critical Challenges

Material supply chain related challenges | Human resource supply chain related challenges |

L1 – Weather Change (Precipitation, etc.) | D1 – Inadequate planning of precast works |

L3 – Transport Regulation Restrictions | D2 – Approvals from regulatory authorities (delays) |

PS2 – Inadequate site / storage space | D3 – Changes in specification |

PS3 – Accessibility to Site (obstructions) | S1 – Disparities in received information from designers and contractors |

PS4 – Reduction in efficiency of resource utilization rate on site | C1 – Late client payment |

PS6 – Inaccuracy of Cast in-situ Works |

These challenges are then ranked based on the score of likelihood of occurrence x relative impact (both for cost and time impact). The score is shown below,

Table 3: Rank of Critical Challenges

Material Supply Chain | Human Resource Supply Chain | ||||||||||

Challenge | L1 | L3 | PS2 | PS3 | PS4 | PS6 | D1 | D2 | D3 | S1 | C1 |

Relative Cost Impact | 40.0 | 32.0 | 32.5 | 27.0 | 29.8 | 72.0 | 76.5 | 58.5 | 68.0 | 71.3 | 67.5 |

Relative Time Impact | 40.0 | 12.0 | 39.0 | 33.8 | 31.5 | 64.0 | 81.0 | 61.8 | 64.0 | 66.5 | 63.0 |

RANK | 2 | 6 | 3 | 5 | 4 | 1 | 1 | 5 | 3 | 2 | 4 |

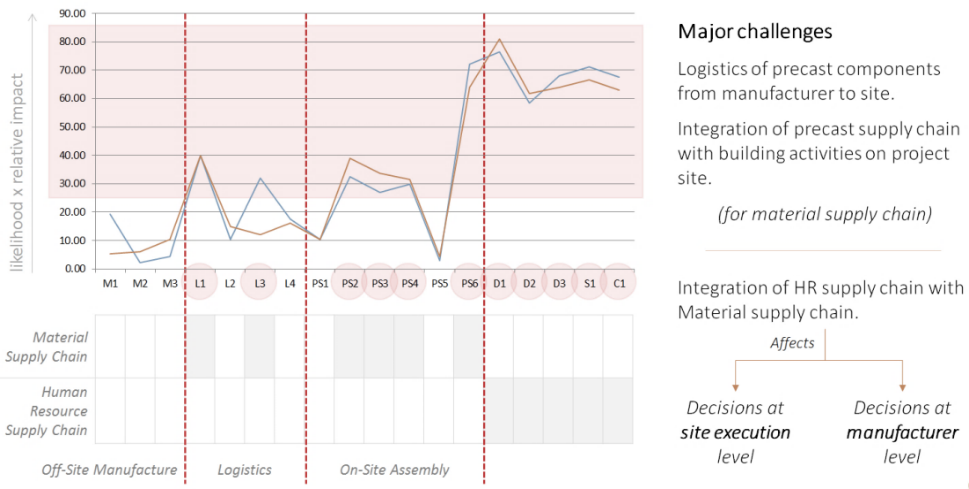

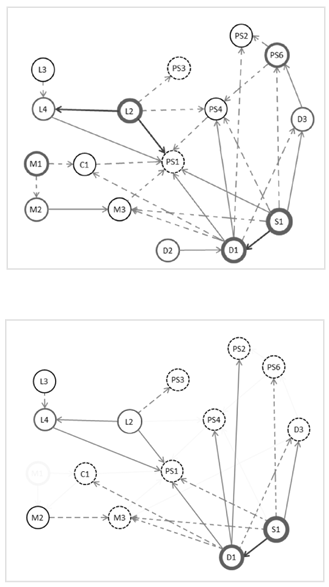

6. Critical Challenges: Plotted against the precast project supply chain

Figure 3 suggested that major challenges in the prefabricated building supply chains are towards the downstream of the project supply chain network. The impact is significant for post manufacture stages within the supply chain and increases downstream up until the project site parameters of the supply chain, where the synchronic interdependencies arise.

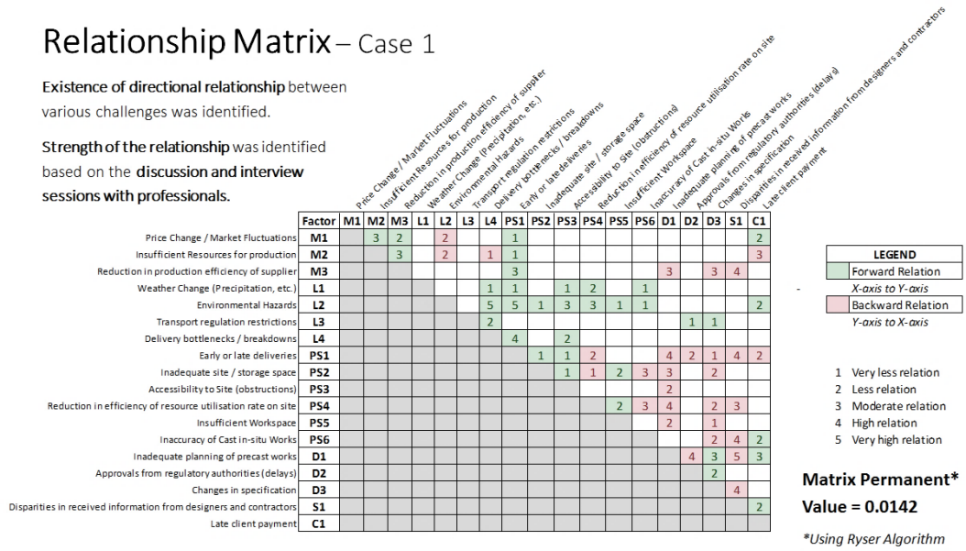

7. Inter-relationship of Supply Chain Challenges

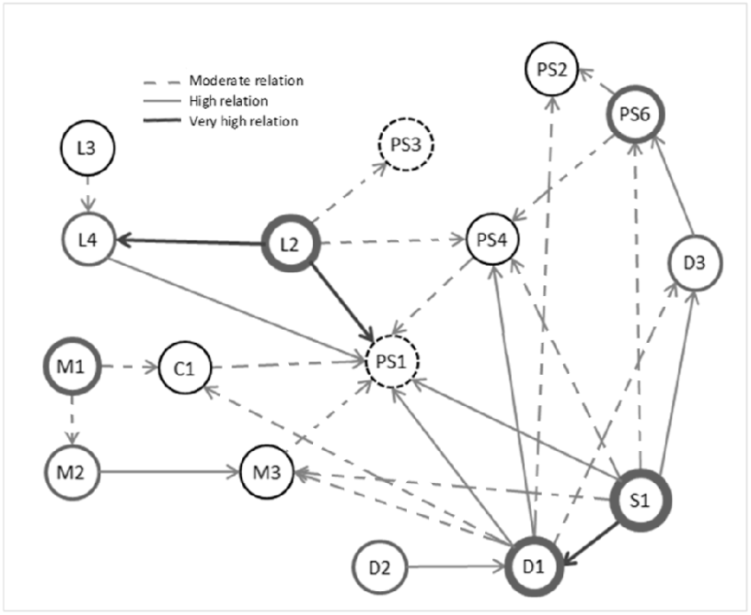

Existence of directional relationship between various challenges and its strength was identified on the basis of literature; and discussion and interview sessions with professionals (responders) from the case specific supply chains. A relationship matrix (Figure 4) is developed using the obtained information, which is used to calculate the matrix permanent values to represent the relative stability of the supply chains as compared to each other. This matrix also helps in identifying the dominant and critical relations among the challenges, and eventually gives the major underlying causes (external and internal factors) of the repercussions within the supply chains of prefabricated building construction.

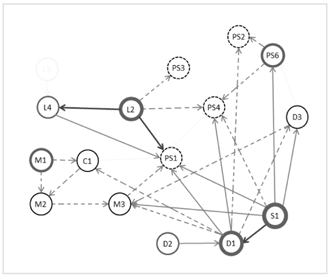

The relationship matrix was used to develop a relationship flow diagram (Figure 5) representing the major relationships (with a value of 3 or more than 3). This flow diagram was analyzed to identify the supply chain challenges that affect multiple parameters of a precast project.

Major causes of existence of various challenges in prefabricated building supply chains were as follows,

S1: Disparities with received information from designers and contractors, is a major underlying cause of existence of challenges – D1, D3, PS1, PS2, PS4, PS5, PS6 & M3.

D1: Inadequate planning of precast works, causes the existence of challenges – D3, PS1, PS2, PS4, PS5, M3 and C1.

M1: Price Change / Market Fluctuations, causes the existence of challenges – M2, M3 and PS1.

L2: Environmental Hazards, causes and affects the existence of challenges – L4, PS1, PS3 and PS4.

L3: Transport Regulation Restrictions, causes and affects the existence of challenges – L4 and PS1.

Above stated underlying causes – S1 and D1 are internal factors and can be controlled to reduce the overall impact on precast project supply chain and optimize the project time and cost. However, the underlying causes – M1, L2, and L3 are external factors, although beyond the control of project parameters and its stakeholders, but due consideration has to be given to these factors to improve supply chain stability.

8. Results and Discussions

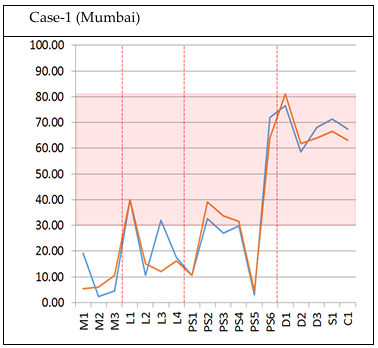

8.1 Analysis of Relative Impact of Challenges across all Case Typologies

Relative impact on project cost and time in Case-2 is lower than in Case-1 because the supplier in Case-2 undertakes precast projects which involve the manufacture and supply of highly repetitive components like modular RCC wall panels, RCC planks for boundary walls, etc. The standardization of component sizes and shapes in Case-2 improves the efficiency of transportation of these panels, resulting in lowering the logistics cost and reducing schedule deviations. Moreover, projects undertaken by the supplier in Case-2 has lower dependency on cast in-situ works, which reduces the likelihood of occurrence of challenges such as, inaccuracy of cast in-situ works, etc. and also reduces the relative impact of these challenges.

Figure 6: Relative Impact across all Case Typologies

Relative impact in the Case-1 and Case-3 is higher than in Case-2 because of the large range of customizable building components, as opposed to the supplier in Case-2. This reduces financial efficiency of the logistics operations of the project because of high variation in sizes & shapes of the manufactured components. The projects undertaken by suppliers in Case-1 and Case-3 involve substantial cast in-situ works along with precast works, making the projects more susceptible to project site related challenges. This higher susceptibility increases the likelihood of occurrence and impact of these challenges arising during the project timeline.

Relative impact in Case-3 is lower as compared to Case-1 because of the differences in supply chain configurations between the two. The large scale projects (as compared to Case-1) undertaken by the supplier in Case-3 benefits from economy of scale. Larger production capacity with high raw material and finished product storage space in Case-3 reduces the susceptibility of precast projects to the site related challenges. In-house logistics department in Case-3 reduces the susceptibility of precast projects to logistics related challenges. Moreover, with respect to the challenges of weather change (L1), the supplier in Case-1 is more prone because of its proximity to Mumbai city.

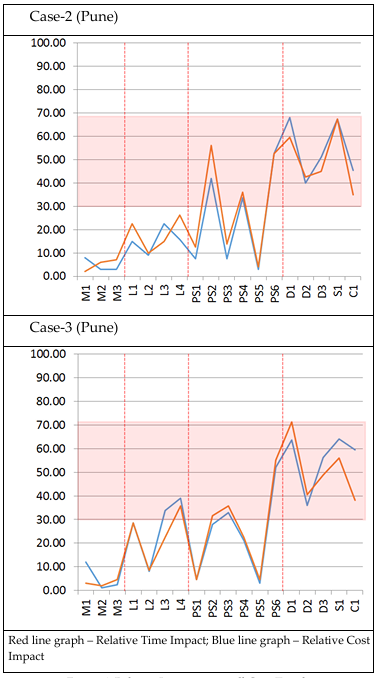

8.2 Analysis of Relationship Matrix of Challenges across all Case Typologies

The supply chain of Case-1 consists of a total of 28 critical relations (17 moderate, 8 high and 3 very high relations) indicating a higher susceptibility to impact to project cost and time. In the configurations and features of Figure 7, the critical relations reduced to 25 (14 moderate, 8 high and 3 very high relations). Implying that supply chain in Figure 7 (Case-2) is slightly less susceptible to impact to project time and cost, as compared to Figure 7 (Case-1).

In Figure 8 (Case-3), the critical relations are reduced to 17 (9 moderate, 7 high and 1 very high relations), which is substantially lower than the relations in Figure 7 (Case-1 and Case-2). Configuration and geophysical mapping of supply chain in Figure 8 (Case-3) renders it least susceptible to impact to project time and cost.

This is also evident by comparing the matrix permanent values (Table 7) representing the relative stability (Higher values of matrix permanent indicate a lower relative stability) of the considered supply chains, which were calculated using the relationship matrix.

Table 4: Matrix Permanent Values (Ryser Algorithm) for all Cases

Case-1 (Mumbai) | Case-2 (Pune) | Case-3 (Pune) |

0.0142 (matrix permanent = 100.46 while considering relative impact values) | 0.0050 (matrix permanent = 27.96 while considering relative impact values) | 0.0007 (matrix permanent = 5.133 while considering relative impact values) |

9. Conclusion

Prefabricated building construction is a growing industry in India consisting of its challenges pertaining to dimensions of construction implementation, architectural performance, social climate & public opinion, costing, and supply chain management. Across these dimensions, major challenge was integration of various components of supply chain in a prefabricated building project including the material and human resource supply chain networks. This research explored the challenge in supply chain integration by studying case of prefabricated building construction supply chains with different configurations, geophysical profile and project typologies to understand the relation among supply chain challenges and variation in relative impact on project time and cost, within the supply chain and across the different supply chains.

The relative impact analysis of identified challenges suggested that major challenges in the prefabricated building supply chains are towards the downstream of the project supply chain network. Bullwhip effect of the critical challenges in supply chain affected the delivery schedule of precast component and logistics cost upstream in the supply chain and the resource utilization rate on the construction site greatly.

Various external and internal underlying causes of disturbances in supply chain processes were identified from the analysis of relationship matrix and flow diagram for each of the considered cases. This indicated that factors, (internal factors) S1 – Disparities with received information from designers and contractors, D1 – Inadequate planning of precast works, (external factors) M1 – Price Change / Market Fluctuations, L2 – Environmental Hazards, and L3 – Transport Regulation Restrictions; were major contributors to existence of various other challenges in the supply chain. Hence, considerations to mitigate the impact of these challenges will reduce their repercussions throughout the prefabricated building construction supply chain.

Conflict of Interest

The authors declare no conflict of interest.

- P. Behera, R.P. Mohanty, & A. Prakash, “Understanding Construction Supply Chain Management” Production Planning & Control, vol. 26, no.16, pp. 1332–1350, 2015, doi 10.1080/09537287.2015.1045953.

- Butković, L. Lovrenčić, A. Grilec, and J. Mikulic. “Supply Chain Management in the Construction Industry – A Literature Review.” International OFEL Conference on Governance, Management and Entrepreneurship, 2016: pp. 798-811.

- L. Bankvall, L. E. Bygballe, A. Dubois, & M. Jahre, “Interdependence in supply chains and projects in construction” Supply Chain Management: An International Journal, vol. 15, no. 5, pp. 385–393. 2010, doi 10.1108/13598541011068314.

- Chase, B. Richard, R. Shankar, F. Robert Jacobs, and N. J. Aquilano “Operations and Supply Management” 12th. Delhi: Tata McGraw-Hill , 2010.

- S.K Solanki, VK. Paul,”A Relative Approach for Building Service Life Prediction: A Case of an Office Building at New Delhi” International Conference on ‘Future is Urban (ICFU’21), Volume 1, Nirma University Ahmedabad, Gujarat,2021.

- Yingbo. Ji, Lin Qi, Yan Liu, Xinnan Liu, Hong Xian Li, and Yan Li 2. “Assessing and Prioritising Delay Factors of Prefabricated Concrete Building Projects in China.” Applied Sciences, vol.8, pp. 1-16, 2018.

- Wang, Zhong-Lei, Hou-Cai Shen, and Jian Zuo. “Risks in Prefabricated Buildings in China: Importance-Performance Analysis Approach.” Sustainability, vol.11, pp. 1-13,2019.

- L. Jiang,Li. Zhongfu , Li. Long, and G. Yunli. “Constraints on the Promotion of Prefabricated Construction in China.” Sustainability, vol. 10 pp. 1-17,2018.

- M. Arif, D. Bendi, A Sawhney, and K C Iyer. “State of offsite construction in India-Drivers and barriers.” Journal of Physics: Conference Series, pp. 1-8, 2012.

- A. Mills, Z. Xiaolin, and R. Reed. “Factors impeding the offsite production of housing construction in China An investigation of current practice.” Construction Management and Economics, pp.1-13, 2013.

- H. Ahmed,Impact Assessment of Construction Supply Chain Risk Changes on Project Time and Cost. Waterloo: University of Waterloo, 2017.

- R. Dasgupta, S.K. Solanki, VK. Paul,2021, Post-pandemic impact on planning of district hospitals in India International Journal of the Built Environment and Asset Management, vol.2, pp.162–182, 2021.

- Massachusetts Institute of Technology. “SC0x Course: Supply Chain Management.” Cambridge, Massachusetts : edX, 2020.

- D. Doran and M. Giannakis. “An examination of a modular supply chain: a construction sector perspective.” Supply Chain Management: An International Journal vol.16, no. 4, pp.260-270, 2011.

- E. Kapoor, S.K. Solanki, VK. Paul,2021, “Cost Benefit Analysis for Rehabilitation of Buildings: Case of Indian Medical Association, New Delhi” International Journal of Structural Engineering, 2021

- G. Briscoe, A. Dainty,S. Millett, ” Construction supply chain partnerships: skills, knowledge and attitudinal requirements.” European Journal of Purchasing & Supply Management, pp.243-255,2001.

No related articles were found.