A Review on Materials and Experimental Process used in Air-spring

Journal of Engineering Research and Sciences, Volume 1, Issue 7, Page # 29-37, 2022; DOI: 10.55708/js0107005

Keywords: Air spring, Stiffness, Rubber, Fibre, Materials

(This article belongs to the Section Mechanical Engineering (MEE))

Export Citations

Cite

Harsh, K. S. and Razdan, S. (2022). A Review on Materials and Experimental Process used in Air-spring. Journal of Engineering Research and Sciences, 1(7), 29–37. https://doi.org/10.55708/js0107005

Karnam Shri Harsh and Surbhi Razdan. "A Review on Materials and Experimental Process used in Air-spring." Journal of Engineering Research and Sciences 1, no. 7 (July 2022): 29–37. https://doi.org/10.55708/js0107005

K.S. Harsh and S. Razdan, "A Review on Materials and Experimental Process used in Air-spring," Journal of Engineering Research and Sciences, vol. 1, no. 7, pp. 29–37, Jul. 2022, doi: 10.55708/js0107005.

The present paper reviews an air spring, its types and construction, manufacturing process, testing and process of FEA analysis. Air spring is of three types – Sleeve-type air spring (SAS), Rolling-Lobe Air-Spring (RLAS), and Convoluted Air Spring (CAS). Spring stiffness is the main factor during manufacturing; to obtain it by FEA analysis and experimentation process is shown. The essential component is either Natural Rubber or Neoprene Rubber. To provide strength and reduce the chances of puncture, fabrics like Nylon and Polyester are reinforced with the rubber and vulcanised. This paper shows the process for obtaining and manufacturing these materials. Metals like Steel, Aluminium, and zinc alloy are also used in Air spring assembly.

1. Introduction

An air-spring is a bellow made of rubber filled with gas. Air-spring provide a movable spring rate and have flexible load-bearing capacity. The use of pneumatics was started in the early 1900 when it was used as air suspension for the bicycle. It was the first when an air spring was introduced [1]. Slowly, the development of air suspension was seen in motorcycles in 2009 which was manufactured by a company Air Spring Ltd. A few years after the motorcycles were banned. In 1920 air suspension was introduced in automotive by George messier for his manufactured cars and provided air suspensions for aftermarkets.

US Government has also developed the air suspension for aircraft during the second world war to reduce their weight. Slowly, many companies started manufacturing air springs in different models that work in different forms. Mostly these air springs were seen in automobiles back then, but now we can see them as vibration insulators, actuators, laundry machines, textile looms etc. With the increase in the use, it is also required to know the capabilities of the air spring and its characteristics. They also have the advantages of providing adjustable height control and less friction. They are commonly used for vibration isolation and vibration control in suspension. They are also used in auxiliary suspension. The air-spring suspension system has an advantage over the conventional suspension system as it can counter the rollover effect due to crosswind conditions. The air spring framework is situated between the vehicle body and the bogie. Generally found in vehicle suspension frameworks, occasionally connected with a helical spring, they are likewise used to protect vibration in apparatus and as linear or angular actuators. Air springs are utilised using an air blower filling and emptying the air bladder. The load isn’t distributed to the rubber liner. This liner just serves to contain the gas; the weight is connected to a cylinder or dab plate, which is upheld by the air within the bellow [2].

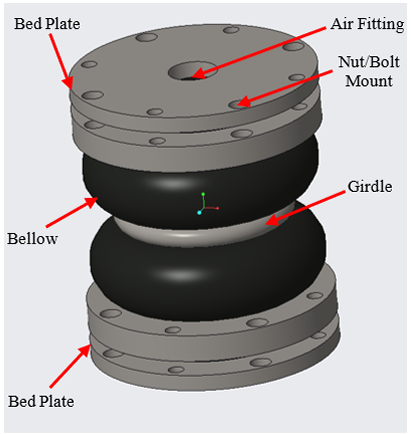

A self-in-out system is enough to keep the air spring’s load stable; incidentally, a different loop is fused into the air inlet and outlet plan. Air springs have numerous unique benefits, for example- low cost, nearly constant natural frequency, ride comfort and road friendliness. Hence, air springs and machine isolators are generally utilised as a vehicular suspensions. They are also used as actuators in transfer stations, bark peeling machines, automotive ram weight adjustments etc. Many researchers have designed different models and designs of Air-springs. The essential components of an Air spring are as shown in Figure.

Construction

Air springs consist of the following components:

- Air fitting – A hole at the top of the air spring allows air in and out. If the spring is fully packed, it will lead to burst, and the spring will fail.

- Nut/bolt mount – During assembly, air spring is required to be fixed with other components for which nut/bolt mount is used.

- Bead plate – These are metal plates fixed rigidly on both sides of the rubber. These are mostly made of steel, zinc Alloy or Aluminium.

- Bellows – A multi-layer material filled with gas or air to withstand the load made up of neoprene or vulcanised rubber. These layers contain rubber and fabric. Fabric is used to make the rubber stronger. With the fabric and vulcanisation process, the stiffness of the rubber is increased.

- Girdle – This is found only in convoluted air springs to divide the rubber into two or three chambers.

Researchers have developed a wide variety of air-spring, explaining the various types and their applications.

Table 1: Types of Air-Spring [3]

Air Spring Types | ||

Sleeve-type air springs | Rolling-lobe air springs | Convoluted air springs |

Sleeve-style air-springs consist of a member having a moulded bed inside. This design results in a smaller overall diameter. A bag of synthetic rubber compounds incorporates the internally mounted spring. | A single rubber cylindrical Bellow depending on its usage and load capacity, rolls outside while folding inside its rubber sheet. Its stroke length is high, and its strength is low. | Bellow springs possess mere lifting and load-carrying capacity. This type of air spring has multiple convoluted chambers and reinforced rubber. These types of springs are available in three configurations – Triple, double, and single chamber design. |

Applications of SAS | Applications of RLAS | Applications of CAS |

Light-duty trucks, Seat suspensions | Rail Vehicles, Heavy load Trucks & Trailers, Ambulance, Buses, Isolators & Actuators in Industries | Robotics – Pick & Place, Automotive Industries, Press machines, Conveyer system, Roll Tensioner, Tractor Suspension |

2. Manufacturing and Materials

Air spring is manufactured to sustain and absorb sudden jerks and can be used for a long time. Replacing the air spring with a coil spring was the most significant challenge. The main element that plays a crucial role is the rubber below, a multi-layer material made of rubber and fabric. The natural rubber must be rolled into sheets, and required materials are mixed with rubber and passed through two rolling mills. The compound must be a homogeneous mixture as output [4]. Fabric is coated with this rubber sheet layer by layer in a sandwich pattern. Fabrics like Nylon and Polyester are used in the manufacturing of air springs. The rubber and fabric reinforcement increases the rubber’s strength for spring [4], [5]. The bond between rubber and fabric should be strong. They should not get air bubbles between them. Generally, adhesives are used for bonding rubber with fabric.

Once the reinforced rubber is dried, it must undergo a vulcanisation process to increase its strength of reinforced rubber. Steel wires are placed between the layers of reinforcements at both ends of the bellows where the bead plate is clamped. Generally, this bead plate and girdle comprises steel, Aluminium, or zinc alloy.

The manufacturing of air springs usually consists of subsequent operations. Production of rubber, coating it to fabric layer, making a reinforced composite, vulcanisation of composite by high pressure and at high temperature, and then clamping it with metal bead plates at both ends.[6]

Rubber is the most crucial element of air spring; two types of rubber are used in all –

I. Natural Rubber

II. Neoprene Rubber

Natural Rubber – Hevea brasiliensis is the primary source of natural latex rubber. It belongs to the Euphorbiaceae family. Some more sources to extract the natural rubber are the Sapotaceae just family (gutta-percha) and Asteraceae families Parthenium argentatum (guayule rubber). The latex is a kind of milky liquid extracted from trees. This liquid contains rubber particles diluted to 15% and solidified with formic acid.[7] The solidified rubber material is passed through the rollers, which compresses the rubber removing water from it and making it into a sheet form. This sheet is later dried with hot air or smoke from the fire. The natural rubber has many grades, but the most distinguished latex and solid grade. We can obtain latex from trees, and the solid grade rubber is solidified in processing centres made of latex. The raw rubber and rolled rubber sheets are machined and milled in roller machines, reducing the molecular weight by breaking down the long chains of the polymer. Cis-1,4 polyisoprene is the chemical name for standard natural rubber and has the longest polymer chain. It has a small number of inorganic salts, lipids, proteins, and other materials. The natural rubber has long polymer chains which are coiled and entangled at room temperature.[8]

After making the rubber sheet, its tensile strength can be increased by the vulcanisation process. We can change the form of rubber from a thermoplastic state to elastomer material by mixing it with Sulphur and lead carbonate and heating this mixture. The reaction time of Sulphur and rubber is slow even at increased heat. To decrease this reaction time, accelerators are added with adhesives like antioxidants, fillers, and plasticisers. 3% weight of Sulphur is added to the rubber mixture and heated between 100 to 200º C during the vulcanisation or curing process. But if the % of Sulphur is increased, it will increase the cross-linking of the polymers, increasing the hardness of material and decreasing its flexibility. It requires 45% of Sulphur to harden the rubber fully. And by adding filler, the strength of the rubber can be increased. The most common filler used is carbon black, and to increase rubber’s tensile strength, we should use fine-sized particles [7]

Table 2: Vulcanised natural rubber properties [9]

Tensile strength (Mpa) | 17.239 to 24.13 Mpa |

Elongation % | 750 to 850 % |

Density (Kg/m3) | 930 Kg/m3 |

Recommended operating temperature (F) | -58 to 179.6 ºF |

Properties of natural rubber

- It has high tensile and tear strength.

- It has good fatigue resistance.

- Excellent handling and tack strength

- It generates low heat as it has low hysteresis.

- Its rolling resistance is also low.

- It is resistant to tearing, chipping, and cutting.

- It is moderately resistant to heat, light, and ozone.

- It is less resistant to petroleum products – gasoline, naptha, and oils.

- The strength of natural rubber can be decreased in high temperatures.

- It is resistant to alkalies, salts and inorganic acids. [9], [10]

Neoprene Rubber – Neoprene rubber, often known as polychloroprene, is a synthetic substance made from polymerised chloroprene. Polychloroprene comprises carbon, hydrogen, and chlorine polymers cross-linked to provide neoprene features, including chemical inertness, heat, oil, water, and solvent resistance. Neoprene is made from acetylene which uses using catalyst converted into vinyl acetylene. The boiling point of vinyl acetylene is 5ºC and forms chlorobutadiene reacting with hydrochloric acid. Chlorobutadiene has a boiling point of 60 ºC. Primarily it is dangerous to the skin if splashed, and if soon be washed with water would still be harmful. Mixing chlorobutadiene with rosin, Sulphur is kept in soap solution and catalyst (salt) is added, which is agitated for two hours. This process gives us neoprene latex. Neoprene undergoes vulcanisation, which is the chemical treatment of synthetic rubber to enhance its properties, as part of its production process. Vulcanisation creates Sulphur bridges that connect individual chloroprene chains to form a larger molecule, resulting in cross-linking of molecules. The quantity of Sulphur links in a batch of neoprene impacts its overall qualities. As a result, depending on how chloroprene is vulcanised and how many Sulphur bonds are formed, neoprene can exhibit a wide range of characteristics without affecting its basic structure [11], [12].

We can get neoprene in different forms depending on the requirement and purpose they are –

- Neoprene sheets. They are useful for making protective gear like wet suits and gloves, but they may even be utilised for landfill liners or protective gear wraps.

- Extruded neoprene. Extrusions of neoprene are used as tubing or window sealing or split into gaskets, washers, or seals.

- Neoprene foam. Because neoprene foam is spongey and thick, it may also be utilised to cushion sporting equipment. It’s also used to insulate industrial machinery and as a weather-stripping material [11].

Properties of neoprene rubber

- It is resistant to heat.

- It is also resistant to cold.

- It is compatible with materials like fabrics and metals.

- It can resist outside atmospheric conditions.

- It is resistant to chemicals and petroleum products as well [11], [12]

During characterization of rubber and elastomers it is essential to know that there are many standards available for testing process. Different types of tension, adhesion and com,pression tests standard are available for characterizing rubber and elastomers –

- ASTM D412 Tension Testing for Rubber and Elastomers

- ASTM D575 Compression Test of Rubber

- ISO 6133 Rubber Tear and Adhesion Strength

- ISO 34-1 & ISO 34-2 Tear Strength of Rubber, Vulcanized or Thermoplastic – Trouser

The Fabrics used for reinforcement are –

- Nylon

- Polyester

Nylon – Nylon is a synthetic material with wide applications due to its transformable characteristics. They can quickly transform into fibres, moulded parts, and films. It also has biocompatible nature. It belongs to the polyamide family, which is a synthetic semi-crystalline polymer.

A polyamide is an amide group bonded with monomers which can either naturally or synthetically be obtained. Naturally, polyamides can be obtained from silk and wool. Synthetic polyamides can be manufactured through Nomex, Kevlar, and Perlon. Synthetic polyamide has three categories polyphthalamides, aromatic polyamide and aliphatic polyamide. Among these, we use semi-aromatic polyamide or aliphatic polyamide for making Nylon. Nylon can be used in many ways by providing a different shape and form by melting and then cooling. It has excellent mechanical properties, which can be further increased by adding other materials and elements. Nylon is used in the textile and food industries and is compatible with human tissues for biomedical implants [13], [14]

Properties of Nylon

- It is a thermoplastic material

- It is a semi-crystalline polymer and shows an amorphous phase after solidification.

- It is a good water absorbent.

- It is resistant to ultraviolet radiation.

- It is resistant to chemicals like alkaline and diluted acids.

- It undergoes Hydrolysis despite being chemical resistant.

- It is a Biocompatible material but can still be harmful and cause infections [14], [15].

Polyester – The common and widely used polyester fibre is polyethene terephthalate which is called PET, which is a synthetic fibre which is produced in huge quantities all over the world. It is a low-cost material and can be used with natural fabrics, which is also a recyclable material, providing convenience in processing and performance. This material has been very likely used on a large scale. Poly-ethylene terephthalate is a product of condensed ethyl Glycol and terephthalic. To successfully manufacture polymerised PET is purity in monomer and moisture-free vessel.

Table 3: Mechanical Properties of types of Nylon [14]

Property | Nylon 6 (toughened) | Nylon 6 (fiber) | Nylon 6 (30 % carbon fiber) | Nylon 66 (toughened) | Nylon 11 (rigid) | Nylon 11 (flexible) | Nylon 12 (rigid) | Nylon 12 (flexible) |

Density (kg/m3) | 1070–1100 | 1130–1150 | 1260–1280 | 1060–1080 | 1020–1040 | 1040–1050 | 1000–1020 | 1030–1040 |

Young’s modulus (GPa) | 0.782–0.976 | 4–5 | 12.9–16.1 | 0.939–1.17 | 1.06–1.33 | 0.35–0.36 | 1.08–1.35 | 0.35–0.42 |

Yield strength (MPa) | 33.1–41.3 | 600–1050 | 131–163 | 36.1–45.1 | 35.4–44.1 | 25–27 | 34.8–43.4 | 22–25 |

Elongation (%) | 37.2–53.5 | 16–19 | 3.01–4.33 | 41–59 | 280–320 | 360–430 | 41–59 | 360 |

Fatigue strength (107 cycles) (MPa) | 40.3–44.5 | – | 55.9–61.7 | 17.6–19.4 | 20–22 | 18–20.4 | 19–21 | 16 |

Toughness (kJ/m2) | 9.72–13 | – | 1.83–2.45 | 8.72–11.7 | 8.07–10.8 | 18.9–19.5 | 8.01–10.7 | 16.7–20.2 |

Humidity absorption @ sat (%) | 2.1–2.9 | 4 – 4.5 | 2–2.6 | 1.8–2.4 | 0.68–0.92 | 0.9 | 0.62–0.84 | 1.2–1.4 |

To make fibre from the polymer, it must be melted down or put into the spinning machine after it achieves the required molecular weight. Obtaining fibre from a spinning machine is called continuous polymerisation. Further PET pallet’s molecular weight can be increased by solid-state polymerisation. At about 160ºC PET chip is dried, crystallised, and heated below the melting point. This process is done in extreme dryness and vacuum [16], [17].

Properties of polyester

- Polyester’s thermal and mechanical properties can be affected or changed by the degree of crystallin.

- Crystallinity and orientation of molecules can increase young’s modulus and break the tension, decreasing break elongation.

- It is resistant to organic acids.

- It is resistant to weak alkaline and partially resistant to strong alkaline.

- It is resistant to oxidant agents such as soaps, bleach, detergent, etc.

- It is resistant to ultraviolet radiation, but its fabrics can get weaker if exposed for a more extended period [17]

Table 4: Physical properties of polyester PET [18]

Crystal habit | Triclinic: one polymer chain per unit cell |

Cell parameters | a = 0.444 nm; b = 0.591 nm; c = 1.067 nm, α = 100 degrees. β = 117 degrees; γ = 112 degrees |

Cell density | 1.52 g/cm3 |

Tm (DSC) | 260ºC-265ºC |

ΔHf | 140 J/g; 33.5 cal/g |

Tg (solid chip) | 79ºC (DSC) |

Tg (drawn fiber) | 120ºC (dynamic loss) |

Specific gravity | 1.33 (amorphous, undrawn), 1.39 (crystalline drawn fibre) |

The metals used for clamping are made of –

- Steel

- Zinc Alloy

- Aluminium

Steel – Steel is an alloy of Iron and carbon with a carbon of 2%, and if the percentage of carbon increases, it is known to be cast Iron. Steel is a widely used material all over the world in many wide ranges of application as construction, mechanical tools, machines, needles etc. Steel is produced by two methods Basic Oxygen Furnace or Electric Arc Furnace. Steel has four types – Carbon Steel, Alloy steel, Stainless steel, and Tool steel [19]

Table 5: Properties of steel for above four types [20]

Properties | Carbon Steels | Alloy Steels | Stainless Steels | Tool Steels |

Density (1000 kg/m3) | 7.85 | 7.85 | 7.75-8.1 | 7.72-8.0 |

Elastic Modulus (GPa) | 190-210 | 190-210 | 190-210 | 190-210 |

Poisson’s Ratio | 0.27-0.3 | 0.27-0.3 | 0.27-0.3 | 0.27-0.3 |

Thermal Expansion (10-6/K) | 11-16.6 | 9.0-15 | 9.0-20.7 | 9.4-15.1 |

Melting Point (°C) | 1371-1454 | |||

Thermal Conductivity (W/m-K) | 24.3-65.2 | 26-48.6 | 11.2-36.7 | 19.9-48.3 |

Specific Heat (J/kg K) | 450-2081 | 452-1499 | 420-500 | |

Electrical Resistivity (10-9W-m) | 130-1250 | 210-1251 | 75.7-1020 | |

Tensile Strength (MPa) | 276-1882 | 758-1882 | 515-827 | 640-2000 |

Yield Strength (MPa) | 186-758 | 366-1793 | 207-552 | 380-440 |

Percent Elongation (%) | 10-32 | 4-31 | 12-40 | 5-25 |

Hardness (Brinell 3000kg) | 86-388 | 149-627 | 137-595 | 210-620 |

Aluminium – Aluminium and its alloys are widely used in industries due to its suitable physical, mechanical and tribological properties. It is the third most common metal in the earth’s crust. It has FCC type structure which is ductile at ambient temperature, which makes it easily machinable. It has a lower melting temperature than other engineering metals. Aluminium is found in two states after production – the primary and alloy states. Aluminium alloys are used in aerospace and automotive industries as they can replace steel and Iron due to their promising strength-to-weight properties [21]

Table 6: General properties of Aluminium [22]

Density (kg/m3) | 2.5 x 103 to 2.9 x 103 |

Yield strength (Pa) | 3 x 107 to 5 x 108 |

Tensile strength (Pa) | 5.8 x 107 to 5 x 108 |

Elongation (%Strain) | 0.01 – 0.44 |

Hardness (Pa) | 1.18 x 108 to 1.48 x 109 |

Melting Temperature (ºC) | 475 to 677 |

Fracture Toughness (Pa/m0.5) | 2.2 x 107 to 3.5 x 107 |

Young’s Modulus (Pa) | 6.8 x 1010 to 8.2 x 1010 |

Characteristics of Aluminium –

- Aluminium is light weighted.

- It is a durable material.

- It is corrosion-resistant.

- It can be easily machined

- It doesn’t have magnetic nature

- It is an electric and heat conductor.

- It possibly has a wide range of surface treatments.[22], [23]

Zinc Alloy – Zinc is the next most used metal after iron, Aluminium and copper. Primarily zinc is used for removing corrosion and galvanising. Using zinc for galvanising increases iron and steel recyclability. Brass is the zinc and copper alloy with adding some tin and alloy. Previously zinc was obtained from zinc oxide ores, but sulphide ore was also discovered later, which is in large quantity present on earth, so after this sulphide ore is discovered, zinc is also produced from zinc sulphide.[24]

Table 7: Properties of zinc alloy [25]

Density (g/cm³) | 6.3 |

Elastic modulus (GPa) | 86 |

Tensile strength (MPa) | 370 |

Elongation (%) | 8 |

Heat transfer rate (W/(m·K)) | 120 |

Melting point (°F) | 716 |

Coefficient of thermal expansion (K-1) | 2.3 ✕ 10-5 |

Yield strength (MPa) | 290 |

Electrical conductivity (S/m) | 1.624 * 10-8 |

3. Vulcanization Process

The process of vulcanisation is an important part when it comes to the use of rubber for goods. When we use rubber for tires and spring-like air products, or can say mechanical products which require strength, vulcanisation is necessary. Without it, rubbers don’t have the strength to regain their original shape when a high load is applied. The temperature required for the vulcanisation process is about 140° -180°C.

4. Testing and analysis of Air Spring Stiffness Test

Stiffness- Stiffness is the resisting force of an object when an external force is applied to it. In other words, materials with more flexibility have less stiffness. Stiffness can be calculated by –

$$K = \frac{F}{\delta}$$

We can use FEA (Finite Element Analysis), Experimental process and calculations to calculate the stiffness of the air spring. Many researchers have come up with different ways to obtain the vertical stiffness of air springs.

Most of the stiffness of the spring is based on the air inside the rubber bellows. So, the stiffness of spring is sum of the stiffness of air column inside the spring and the stiffness of rubber bellow.[26]

FEA Analysis

For the analysis of an air spring, we must mainly consider two points, the air conditions or can say air pressure inside the spring and the second is the meshing elements of the model.

FORTRAN – It is a coding language software in which we can write the programs and can develop FEM code which can handle the contact problem for incompressible rubber part analysis.[27]

ABAQUS – It gives a tremendous feasible result in boundary conditions of the air. In ABAQUS programming, the component type FAX 2 can be chosen, which supplies an extra degree 8 to assess the inside pressure of the airbag. Also, during the deformation of the airbag, mainly the elastic material distorted intensely, the meshing may be done in the ANSA programming to ascertain a right and concurrent outcome.[28]

ANSA – It is a unique software used for pre-processing and for meshing. Unlike other software, we can have a good association between CAD models and the mesh created in ANSA.

ANSYS – ANSYS is user-friendly software. One can import the geometry from CAD software and can work in ansys with ease. We can add materials properties of rubber in engineering data and rest boundary conditions in the model window.

Boundary conditions needed to apply are the base of the air spring should be fully fixed and force applied from the top.

Test process

Before proceeding, it is necessary to know the basic process for obtaining the stiffness of an Air spring. The Air spring must be placed on a flat surface and clamped rigidly, allowing the spring to get into an equilibrium state and record the height. Add weights and record the changes in height. Then, the stiffness can be calculated by the relation between force and deflection.[29]

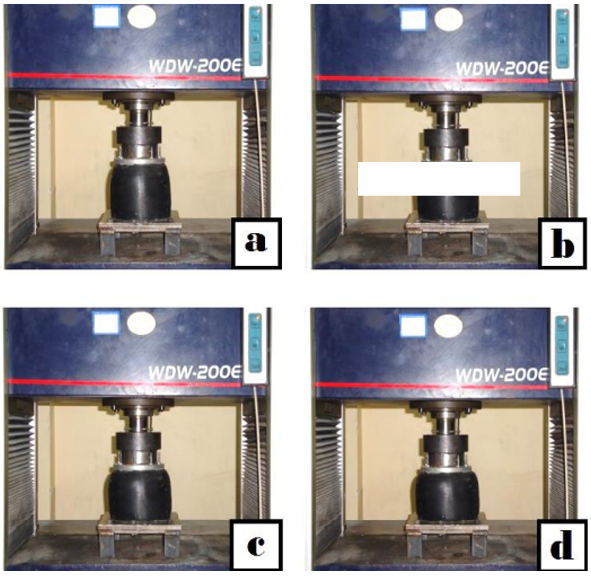

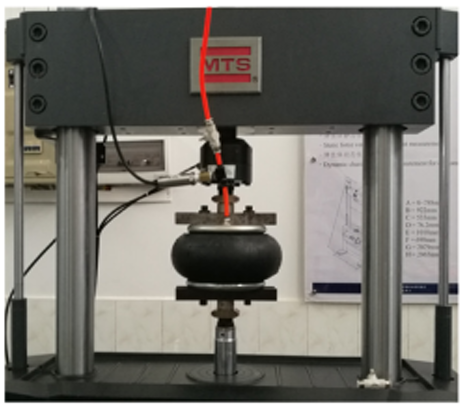

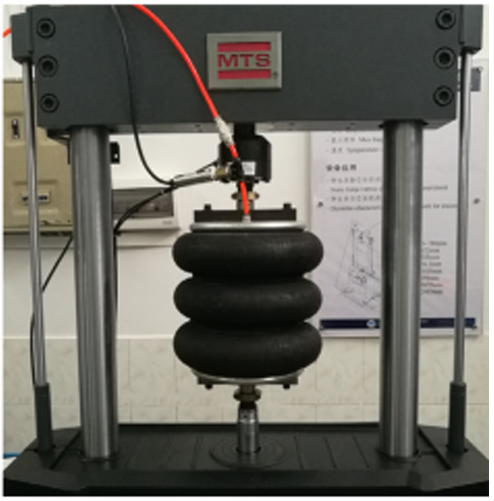

Stiffness can be calculated based on mathematical models and algorithms derived from explicit and implicit algorithms.[30] We can use Universal Testing Machine for experimentation. Clamping air spring in both the jaws of UTM and leaving it to get in an equilibrium state. By providing the load to the electrical UTM machine, we can get the deflection of the air spring, and by calculating the relation of force and deflection, we can get the stiffness value [31], [32].

A blast test can be performed by mechanically assembling the test machine, which requires the top and bottom of the spring to be fixed and the pressure inside the spring to be increased. The blasting pressure for an air spring should be three times that of the normal pressure of the spring. To get this during experimentation, it is recommended to use fluid and create the pressure required for the test [6].

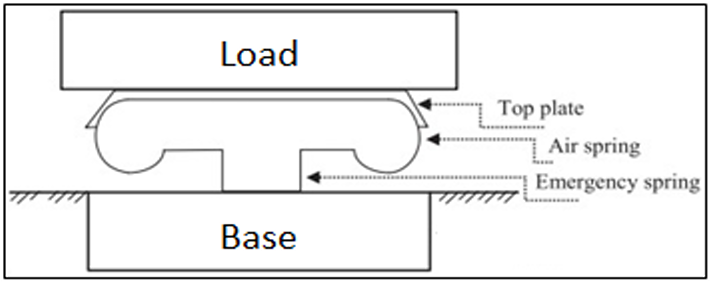

In figure 2 it is shown the setup required for stiffness calculation of an Air-spring Displacement of the spring is calculated by applying load at its top and the bottom should be fixed. Based on this some researches have tested air-springs. These experimental setups are shown below.

These setups shows that the UTM machines are mostly used as experimental setups for testing stiffness. Where as for blast test the setup is same as the above but instead of applying load we have to fix both the sides of air spring and should add pressurized water to it.

5. Conclusion

A properly designed air spring should have a low vertical stiffness for improved low-frequency vibration isolation and a significant high one to reduce suspension compression under static load. FEM can reduce the effort of experimental analysis. The results of FEM are reliable. Both experimental and analytical process for vertical stiffness gives correct results. Tables and Figures can be single or double columns for double-column use section breaks.

Conflict of Interest

The authors declare no conflict of interest.

- ARCHIBALD SHARP, WILLIAM THOMAS SHAW – “Improvements in Cycle” GB190100764A – 1901

- Pak Kin Wong, Zhengchao Xie, “Analysis of automotive rolling lobe air spring under alternative factors with finite element model,” Journal of Mechanical Science and Technology, 28, no. 12, pp. 5069-5081, 2014, doi: 10.1007/s12206-014-1128-9.

- un-Jie Chen, Zhi-Hong Yin, Subhash Rakheja, Jiang-Hua He, Kong-Hui Guo, “Theoretical modelling and experimental analysis of the vertical stiffness of a convoluted air spring including the effect of the stiffness of the bellows,” Proc IMechE Part D: J Automobile Engineering, vol. 232, no. 4, pp. 547-561, 2017, doi:10.1177/0954407017704589.

- Mohsin Noori Hamzah, Mahmood Shakir Nima, “Experimental and Numerical Investigations of an Inflated Air-Spring Made of Fiber-Reinforced Rubber,” Al-Qadisiyah Journal for Engineering Sciences, Vol. 8, no.3, pp. 355-368, 2015.

- Hongguang Li, Konghui Guo, Shuqi Chen, Wei Wang, Fuzhong Cong, “Design of Stiffness for Air Spring Based on ABAQUS”, Mathematical Problems in Engineering, vol. 2013, pp. 1-5, Article ID 528218, doi:1155/2013/528218.

- Burhan Sarıoglu, Ali Durmus, “Manufacture and Testing of Air Springs Used in Railway Vehicles,” Arabian Journal for Science and Engineering, vol. 44, no. 9, pp. 7967-7977, 2019 doi:1007/s13369-019-03981-w.

- http://www.industrialrubbergoods.com/natural-rubber.html – Natural rubber

- Thoguluva Raghavan Vijayaram – “A TECHNICAL REVIEW ON RUBBER,” International Journal on Design and Manufacturing Technologies, Vol.3, No.1, pp. 25-37, 2009.

- Harris, A. Piersol, Harris, Mechanical properties of rubber, shock and vibration handbook 5th edition chapter 33, , McGraw-Hill, 2002.

- Marie-Noëlle Crepy, Donald Belsito, chapter 67 Rubber Kanerva’s Occupational Dermatology, Third Edition, Springer 2020

- https://www.thomasnet.com/articles/plastics-rubber/traits-applications-neoprene/ – Neoprene rubber

- R. BRIDGWATER, E. I. du Pont de Nemours & Companq-, Inc., Wihnington, Del, “Neoprene, The Chloroprene Rubber,” Industrial and Engineering Chemistry, vol. 32, no. 9, pp. 1155-1156, doi:10.1021/ie50369a004.

- I M Hanif, M R Noor Syuhaili, M F Hasmori, S M Shahmi, “Effect of nylon fiber on mechanical properties of cement based mortar”,” 2017 IOP Conf. Series: Materials Science and Engineering”, vol. 271, pp. 1-7, doi:10.1088/1757-899X/271/1/012080.

- Mohamadreza Shakiba, Erfan Rezvani Ghomi, Fatemeh Khosravi, Shirzad Jouybar, Ashkan Bigham, Mina Zare, Majid Abdouss, Roxana Moaref, Seeram Ramakrishna, “Nylon—A material introduction and overview for biomedical applications” Polymers Advanced Technologies, vol. 32, no. 9, pp. 3368-3383, 2021, doi:10.1002/pat.5372.

- David J. Barillo, Morano Pozza b, Mary Margaret-Brandt, “A literature review of the military uses of silver-nylon dressings with emphasis on wartime operations,” Elsevier: burns, vol. 40, no. 1 pp. 24–29, 2014, doi:10.1016/j.burns.2014.09.017.

- Asnake Ketema, Amare Worku, “Review on Intermolecular Forces between Dyes Used for Polyester Dyeing and Polyester Fiber” Journal of Chemistry 2020, article ID 66284 04, pp. 1-7, doi:10.1155/2020/6628404.

- M. HANSEN P. B. SARGEANT E. I. du Pont de Nemours & Co., Inc.- “Fibers, Polyester” – Kirk-Othmer Encyclopedia of Chemical Technology. 1st ed., vol. 13, pp. 840–847, 2000, doi:10.1002/0471238961.1615122508011419.a01.

- Michel Jaffe, Anthony J. Easts, Xianhong Feng, “8-Polyester fibers,” Thermal Analysis of Textiles and Fibers, woodhead Publishing, Elsevier 2020, pp. 133-149, doi:10.1016/B978-0-08-100572-9.00008-2.

- Edward F. Wente, “Steel” Encyclopedia Britannica, 2019, https://www.britannica.com/technology/steel.

- Steel & Steel Alloy Stamping, Trident components, https://www.tridentcomponents.com/steel-stamping/.

- A. Elhadari, H.A. Patel, D.L. Chena, W. Kasprzak, “Tensile and fatigue properties of a cast aluminum alloy with Ti, Zr and V additions,” Materials Science and Engineering: A, vol. 528, no. 28, pp. 8128–8138, 2011, doi:10.1016/j.msea.2011.07.018

- https://dielectricmfg.com/knowledge-base/aluminum/ – Aluminium

- Alexopoulos, Sp.G. Pantelakis – “Quality evaluation of A357 cast aluminum alloy specimens subjected to different artificial aging treatment” Materials and Design, vol. 25 no. 5 pp. 419–430, 2004, doi:10.1016/j.matdes.2003.11.007.

- Annalisa Pola, Marialaura Tocci, Frank E. Goodwin, “Review of Microstructures and Properties of Zinc Alloys,” Metals, vol. 10, no. 2, pp. 1-16, 2020, doi:10.3390/met10020253.

- https://matmatch.com/learn/material/zinc-alloy – “Zinc Alloys: Properties, Production, Processing and Applications,” Matmatch.

- Jiatong Ye, Hua Huang, Chenchen He, Guangyuan Liu, “Analysis of Vertical Stiffness of Air Spring Based on Finite Element Method”,” 2018 MATEC Web of Conferences, vol. 153, article no. 06006, 2017, pp.1-5, doi:10.1051/matecconf/201815306006.

- Tamas Mankovitsa, Tamas Szabób, “Finite Element Analysis of Rubber Bumper Used in Air-springs,” Procedia Engineering, Elsevier, vol. 48 388 – 395, 2012, doi:10.1016/j.proeng.2012.09.530.

- Jian Sun, “Calculation of Vertical Stiffness of Air Spring with FEM”,” 2011 In Greece: 4th ANSA & μETA International Conference, 2011

- Surbhi Razdan, P. J. Awasare, Suresh Y. Bhave, “Active Vibration Control using Air Spring,” Inst. Eng. India Ser. C vol. 100, no. 1, pp. 1-12, 2019, doi:10.1007/s40032-017-0424-4

- XU Wei, HE Lin, SHUAI Chang geng and YE Zhen xia, “Stiffness Calculation and Dynamic Simulation of Air Spring” International design engineering technical conferences & Computers and Information in Engineering Conference, 1395-1399, 2005, doi:10.1115/DETC2005-84338.

- Jun-Jie Chen, Zhi-Hong Yin, Xian-Ju Yuan, “A refined stiffness model of rolling lobe air spring with structural parameters and the stiffness characteristics of rubber bellows,” ELSEVIER- Measurement, 169, pp. 1-14, 2021, doi:10.1016/j.measurement.2020.108355.

- Di Qu, Xiandong Liu, Guangtong Liu, Yifan Bai1, Tian He, “Analysis of vibration isolation performance of parallel air spring system for precision equipment transportation,” Measurement and Control, Vol. 52, no. 3-4, pp. 291–302, 2019, doi:10.1177/0020294019836122.

No related articles were found.