Application of deuterium Oxide (D<sub>2</sub>O) Isotope Tracing Technique for Land Grid Array Package Failure Analysis

Journal of Engineering Research and Sciences, Volume 3, Issue 1, Page # 1-5, 2024; DOI: 10.55708/js0301001

Keywords: Land grid array (LGA) package, Deuterium oxide (D2O), Isotope tracing, HAST, moisture penetration

(This article belongs to the Section Electronic Engineering (EEE))

Export Citations

Cite

Lois, L. J. , Qing, L. , Jing, Q. , Qing, Y. , Xi, Z. , Younan, H. and Xiaomin, L. (2024). Application of deuterium Oxide (D<sub>2</sub>O) Isotope Tracing Technique for Land Grid Array Package Failure Analysis. Journal of Engineering Research and Sciences, 3(1), 1–5. https://doi.org/10.55708/js0301001

Liao Jinzhi Lois, Liu Qing, Quan Jing, Ye Qing, Zhang Xi, Hua Younan and Li Xiaomin. "Application of deuterium Oxide (D<sub>2</sub>O) Isotope Tracing Technique for Land Grid Array Package Failure Analysis." Journal of Engineering Research and Sciences 3, no. 1 (January 2024): 1–5. https://doi.org/10.55708/js0301001

L.J. Lois, L. Qing, Q. Jing, Y. Qing, Z. Xi, H. Younan and L. Xiaomin, "Application of deuterium Oxide (D<sub>2</sub>O) Isotope Tracing Technique for Land Grid Array Package Failure Analysis," Journal of Engineering Research and Sciences, vol. 3, no. 1, pp. 1–5, Jan. 2024, doi: 10.55708/js0301001.

A land grid array (LGA) is an integrated circuit design with a grid of contacts connected to other components of a printed circuit board. LGA is used for various high-speed and high-frequency applications due to its small terminal parasitic inductance. However, LGA packages are non-hermetic, as most the components of the LGA, like epoxy molding compounds, substrates, and resins are not airtight. These components can absorb moisture from working environment, and the moisture penetration will give rise to package reliability problems. In this study, a batch of LGA packages encountered electrical malfunction after Highly Accelerated Stress Tests (HAST) 85°C/85%RH reliability test 96 hours. The failure mode was causing the connected display panels showing white dots, as the LGA were used to control the external display panels. Although hot spot testing through thermal imaging was performed, it could not locate the failure point of the die. Traditional non-destructive tests, like X-ray inspection and Scanning Acoustic Microscopy techniques were also performed, but they could not detect any defect of the package which may be contributed to their detection limit. It is suspected that penetration of moisture into the LGA package caused electrical failure, however there is no direct proof to demonstrate this presumption. To solve above challenges, this work employed a new deuterium oxide (D2O) isotope tracing method. Both good and bad LGA packages were loaded in the HAST chamber in which normal water (H2O) was fully replaced with heavy water (D2O). Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS) was utilized to detected the D signal in the LGA package. By comparison, it was found that the moisture penetration through the via-resin interface of the bad sample was much faster than that of the good sample. Verification test was performed to replace the bad batch substrate (where moisture penetrated fast), and the new samples all passed the HAST test. It is confirmed that it is the via-resin interface in the substrate of the bad samples causing moisture penetration.

1. Introduction

A land grid array (LGA) is an integrated circuit design with a grid of contacts connected to other components of a printed circuit board. LGA is used for various high-speed and high-frequency application due to its small terminal parasitic inductance. However, LGA packages are non-hermetic, as most the components of the LGA, like epoxy molding compounds, substrates, resins are not airtight. These components can absorb moisture from working environment, and the moisture penetration will give rise to package reliability problems.

In this study, there are 2 batches of LGA packages from 2 different suppliers, called Batch A and Batch B. Batch A packages all passed the Highly Accelerated Stress Tests (HAST) 85°C/85%RH reliability test 96 hours. While Batch B packages encountered 100% electrical malfunction after HAST 96 hours. The failure mode was causing the connected display panels showing white dots, as the packages were used to control the external display panels. Although hot spot testing through thermal imaging was performed on the bad samples, it could not locate the failure point of the die. Traditional non-destructive tests, like X-ray inspection and Scanning Acoustic Microscopy techniques were also performed, but they could not detect any defect of the package which may be contributed to their detection limit. It is suspected that penetration of moisture into the LGA package caused electrical failure, however there is no direct evidence to find out the moisture penetration path.

To solve above challenges, this work employed a new deuterium oxide (D2O) isotope tracing method. In D2O, deuterium (D) is a stable hydrogen (H) isotope whose nucleus consists of one proton and one neutron. In nature the D-to-H (D/H) ratio is about 1.55 x 10-4 [1]. In this work, both Batch A good samples and Batch B bad samples were loaded in the HAST chamber in which normal water (H2O) was fully replaced with heavy water (D2O). During the HAST process, the D2O moisture will penetrate the packages through the non-hermetic packaging materials or their interfaces. After that, the samples were discharged from HAST chamber, and the presence of D in the samples were detected by Time-of-Flight Secondary Ion Mass Spectrometry (ToF-SIMS).

The results showed that moisture penetration through the via-resin interface of the bad sample was much faster than that of the good sample. It is obvious that moisture penetration through the via-resin interface caused moisture-induced failure. Verification test was performed to replace the bad batch substrates (where the vias locate), and all the improved samples passed the HAST test. It is confirmed that it is the via-resin interface in the substrate of the bad samples causing moisture penetration. The data showed that deuterium D2O isotope tracing method is a useful means to detect the moisture penetration path.

2. Experimental

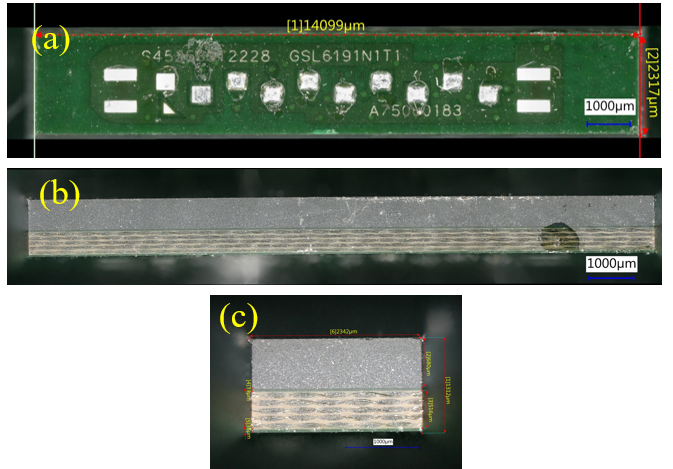

The LGA package (model 6193) studied in this work is shown in Figure 1. The dimension of this package is 14099 x 2317 x 1312 µm (length x wide x thickness). In this study, there are 2 batches of LGA packages from 2 different suppliers (Batch A and Batch B). Batch A packages all passed the HAST 85°C/85%RH reliability test 96 hours. While Batch B packages encountered 100% electrical malfunction after HAST 96 hours.

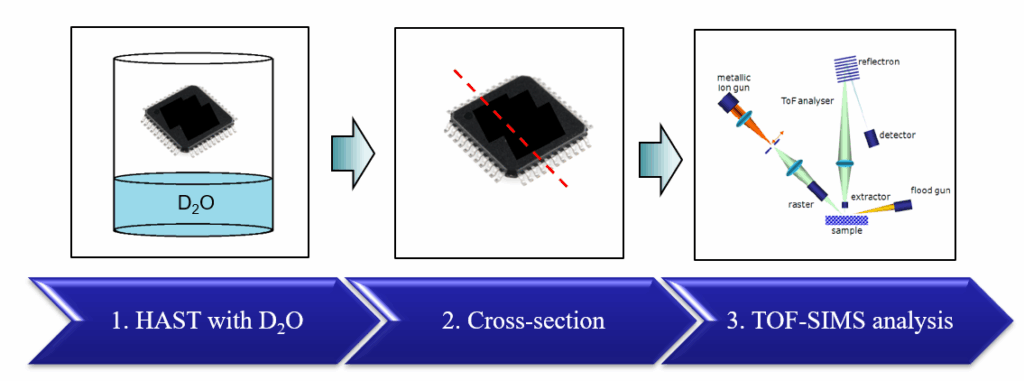

Heavy water method was used to detect the moisture penetration paths in this LGA package. The experiment included below steps, which are illustrated in Figure 2 [2].

1) Sample treated with D2O: The samples were loaded into the HAST chamber with condition of 85°C/85%RH for 1 hour. In the HAST run, H2O was fully replaced by D2O in the chamber. The purpose is to let D2O moisture permeate into the package through the invasion paths.

2) Sample cross-section: The samples were discharged from the HAST chamber, followed by cross-section to expose the possible moisture invasion paths.

3) TOF-SIMS analysis: The samples were analysed by TOF-SIMS to detect the presence of D in the good and bad samples. ToF-SIMS model is ION-TOF SIMS 5 with Primary Ion 133Cs+.

3. Results and Discussion

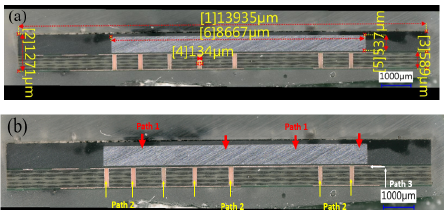

Figure 3a. shows the cross-section and optical image of the LGA sample with dimension measurement. Both Batch A and Batch B are with the same structure. From the structure, it is suggested there are 3 most possible moisture invasion paths to the die. These 3 paths are discussed as below (see Figure 3b).

- Path 1: The die is covered by the epoxy molding compound, which is a non-hermetic material. Therefore, moisture can permeate directly through the molding compound from the top to the die (see the red arrow in Figure 3b).

- Path 2: There are copper (Cu) vias embedded in the substrate under the die. The vias are filled with resin (model PHP-900 IR-6P). As the resin is a non-hermetic material, it is also a moisture invasion path. Moisture could penetrate from the substrate bottom to the die through the via resin (see the yellow arrow in Figure 3b).

- Path3: Moisture can penetrate through the substrate to the die where there is no Cu layer (see the white arrow in Figure 3b).

There are also other moisture penetration paths to the die. However, from this LGA structure, these 3 paths should be the fastest penetration paths suggested by the authors.

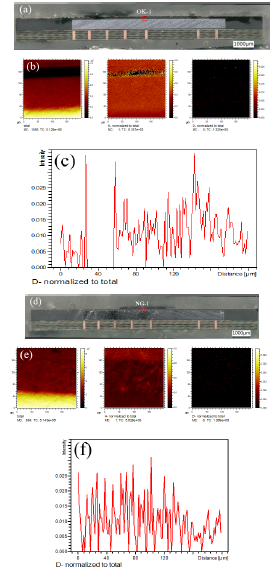

TOF-SIMS surface scanning was performed at both Batch A good samples and Batch B bad samples. Figure 4 shows the TOF-SIMS surface scanning areas and results of the path 1, i.e., epoxy molding compound above the die.

Figure 4a presents the TOF-SIMS surface scanning areas of path 1 in the good sample, called area OK-1. The scanning area is 200µm x 200µm. D ion mapping result of OK-1 was showed in Figure 4b. For easy observation the D concentration, the D ion mapping was converted to intensity profile from surface of the molding compound to the die (see Figure 4c). It can be observed that weak D signal in OK-1 area. Same TOF-SIMS surface scanning areas was performed on the path 1 in the bad sample, called area NG-1 (see Figure 4d). D ion mapping of areas NG-1 was presented in Figure 4e, and D ion intensity profile from surface of the molding compound to the die was presented in Figure 4f. Compared the D ion intensity of the OK-1 and NG-1, there is no obvious difference. Weak D signal was observed for both areas.

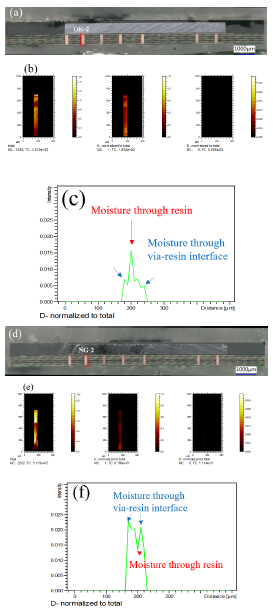

The via-resin areas (path 2) were analysed for both OK and NG samples for comparison purpose. Figure 5a shows the TOF-SIMS surface scanning area at the good sample via (area OK-2). The scanning area is 1000µm x 500µm. Figure 5b shows the D ion mapping of area OK-2. The D ion mapping was converted to intensity profile from left to the right side of the via as shown in Figure 5c. In Figure 5c, it is showed that there is a strong sharp peak at the resin center, which indicates that D2O penetrated through the resin. It is noted that there are small peaks at both sides of the centre peak. It is suggested that moisture penetrated through the interface between the resin and Cu, which contributed to the small peaks.

Same analysis was performed on the bad sample (see Figure 5d-5f). Figure 5d shows the ToF-SIMS surface scanning area of the via in the bad samples, called area NG-2. The D ion mapping is showed in Figure 5e. Figure 5f presents the D intensity profile from left to the right side of the via. In Figure 5c, it is showed that there are 2 strong sharp peaks at the via-resin interface. However, the D intensity of the resin center is much lower. It indicates that in the bad sample, moisture penetration was mainly by the via-resin interface.

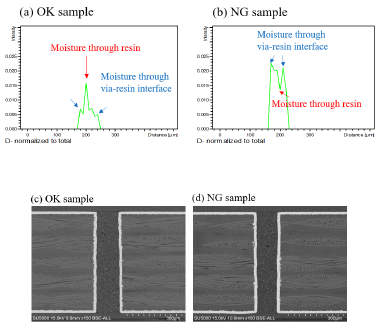

For easy comparison of the OK and NG sample, Figure 6 compared the D signal in the via between these 2 samples. It is obvious that moisture penetration ways are totally different between these 2 samples. In the OK sample, moisture penetrated mainly by the resin (see Figure 6a). Whilst, in the NG sample, moisture penetrated mainly by the via-resin interface (see Figure 6b). It is also noted that D intensity of the NG samples is much stronger than that of the OK sample, indicating more moisture penetration. The next question is why the moisture penetration path and intensity of the OK and NG samples are different? It is suggested that the interfacial adhesion of via-resin of the NG sample is weak which allows easy moisture penetration. SEM characterization was performed to characterize the OK an NG vias (see Figure 6c and 6d). However, there is no obvious gap or delamination of the via-resin interface of the NG sample, neither the OK sample. It is suggested that because the molecular diameter of water molecules (H2O) is about 2.75 angstrom, which is much smaller than that of the resolution of SEM.

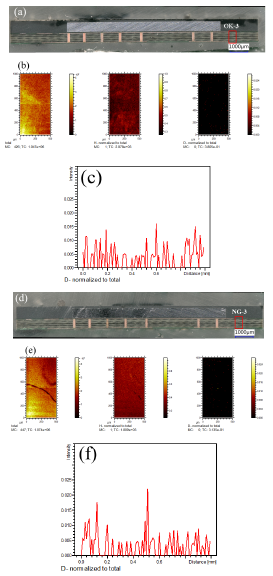

As discussed in previous section, another possible moisture penetration path is through the substrate to the die where there is no Cu layer to block the moisture penetration (Path 3). Figure 7. shows the ToF-SIMS surface scanning on the path 3 areas of both OK and NG samples. Figure 7a-7c shows the OK sample ToF-SIMS scanning area and D data, and Figure 7d-7f shows the NG sample data, respectively. Figure 7c and 7f show the D ion intensity profile from substrate bottom to the top. By comparison Figure 7c and 7f, weak D signal was detected at Path 3 areas for both samples, but there was no obvious different between these 2 samples. So, it is suggested that moisture penetration through Path 3 was weak and was not contributed to the sample failure.

By comparing the moisture penetration data of the 3 paths, i.e., Path 1, 2 and 3, it could be found that both OK and NG sample moisture penetration results of path 1 and 3 are similar (see Figure 4 and Figure 7). The difference is at the Path 2 (see Figure 6). For the NG sample, moisture penetrated through the via-resin interface is much stronger than that of the OK sample. It is suggested that moisture penetration through the via-resin interface contributed to the sample electrical failure, even though no obvious gap at the via-resin interface was observed by SEM. Further verification study was performed to prove the D2O isotope tracing data. In the verification study, the bad batch substrate (where moisture penetrated fast) were replaced by another supplier (Supplier A). In the subsequent HAST, all the new samples passed the HAST test. The HAST results is presented in Table 1. It is confirmed that it is the via-resin interface in the substrate of the bad samples causing moisture penetration. The verification result aligned with what the D2O isotope analysis found.

Table 1: HAST results

Batch | HAST results |

Batch A | 100% passed |

Batch B | 100% failed |

Improved Batch B (Substrate replacement) | 100% passed |

4. Conclusions

In this study, application of deuterium oxide isotope tracing technique was employed for polymer land grid array package failure analysis. The failed sample after D2O moisture treatment was analysed using TOF-SIMS. The results showed that there was a distinct high peak of D ion at the via-resin interface of the NG sample, indicating obvious moisture penetration. Whilst, the D ion at the OK sample was mainly at the resin itself and was much weaker than that of the NG sample. Verification test was performed to replace the bad batch substrate (where moisture penetrated fast), and the new samples all passed the HAST test. It was confirmed that it was the via-resin interface in the substrate of the bad samples causing moisture penetration. This D result was obvious evidence to show the electrical failure of the bad samples was contributed to the moisture concentration through the via-resin interface.

Conflict of Interest

The authors declare no conflict of interest.

Acknowledgment

The authors would like to acknowledge the support from Wintech-nano and Silead.

- J. Lydia Hallis, R. Gary Huss, etc., “Evidence for primordial water in Earth’s deep mantle”, GEOCHEMISTRY, vol. 350, Issue 6262, 13 Nov 2015.

- L. Lois, T. Meng, D. Yong, J. Qiang, Z. Lei, Z. Xi, H. Younan, L. Xiaomin, “Application of deuterium oxide (D2O) isotope tracing technique for encapsulated QFN failure analysis”, Microelectronics Reliability, vol. 135, Aug. 2022.

No related articles were found.