Reviewing the Value of Electric Vehicles in Achieving Sustainability

Journal of Engineering Research and Sciences, Volume 3, Issue 7, Page # 1-10, 2024; DOI: 10.55708/js0307001

Keywords: Battery Electric Vehicles (BEV), Fuel Cell Electric Vehicles (FCEV), Internal Combustion Engines (ICE), sustainability, pollution

(This article belongs to the Section Electrical Engineering (ELE))

Export Citations

Cite

Karunakaran, P. and Osman, M. S. (2024). Reviewing the Value of Electric Vehicles in Achieving Sustainability. Journal of Engineering Research and Sciences, 3(7), 1–10. https://doi.org/10.55708/js0307001

Prashobh Karunakaran and Mohammad Shahril Osman. "Reviewing the Value of Electric Vehicles in Achieving Sustainability." Journal of Engineering Research and Sciences 3, no. 7 (July 2024): 1–10. https://doi.org/10.55708/js0307001

P. Karunakaran and M.S. Osman, "Reviewing the Value of Electric Vehicles in Achieving Sustainability," Journal of Engineering Research and Sciences, vol. 3, no. 7, pp. 1–10, Jul. 2024, doi: 10.55708/js0307001.

This paper aims to narrow the gap of the narratives blasted out in the media (including social media) about electric cars versus the conventional way humans have been transported over the last 100 years. The ICE industry is closely connected to the O & G because 64 % of the output of the O & G industry is utilized for the transportation industry, which ranges from motorcycles, cars, trucks, ships to airplanes. Therefore, these two large industries have a motive to curtail the expansion of the electric vehicles industry. This paper explains why the change from ICE to BEV is needed for the sustainability of human civilization because climate change has been proven to be linked to human activities. Without tailpipe emissions, electric vehicles can immediately clean up pollution in the largest cities of earth where 56 % of humanity lives. The batteries of electric vehicles can also become a citizen sponsored backup battery for the electric power grids, thereby saving even more pollution from the environment. Such a backup for the power grid is necessary for its ability to smoothen the sudden and unexpected spikes in electric consumption or tripping of generators in the power grid.

1. Introduction

Humans walked or ran to their destinations for the longest time. Then they learnt to domesticate horses and cattle to help in their transportation. Then 171 years ago, in 1853 Eugenio Barsanti and Felece Matteucci invented the ICE (internal combustion engine) and like a slow conflagration, ICE went all round the earth to help humanity in actuation and transportation [1].

The internal combustion engine took the idea from the gun or cannon which is to push something out of a barrel, but it was a linear motion. So, weights in the crankshaft were used to smoothen the jerks at the end of linear motions. This was developed over 100 years to almost perfection [2].

Comparatively, electric motors actuate with circular motion, therefore not needing weights to overcome jerks [3]. The electric vehicle (EV) is driven with an electric motor, which was first demonstrated by Micheal Faraday in 1821. As ICEs were being popularized by the likes of Henry Ford and JD Rockefeller, there were people also pushing for transportation to be driven by electric motors. Actually, Edison wanted to use biofuels to help farmers but gave up and started to use Rockefeller’s fuel. JD Rockefeller was a clever businessman who built petrol stations at regular intervals such that people won’t run out of fuel and the market went for it and EVs lost their market share [4]. The much faster refilling of fuel into ICE compared to EV also favored ICE; today this problem is gradually being solved with transformers increasing the voltage at which the BEV (battery electric vehicle) can be charged [5].

The Japanese then took precision to the next level mainly as an outcome of Dr. Deming teaching them statistics after WWII. Dr. Deming was a PhD in Physics who helped develop statistics under Dr. Walter Andrew Shewhart of the Bell Laboratories in New York. They came up with the use of statistics in the manufacture of military equipment in the USA. Guns used to get jammed in battlefields and introducing statistics into armament factories reduced incidences of these happening greatly. Dr. Deming was later invited to Japan by General MacArthur to help with the first post war census. Then in 1950 the general also invited Dr. Deming to the Japanese Union of Scientists and Engineers (JUSE) to talk about statistical process control which is the first time Japanese manufacturers got interested in the use of statistics in manufacturing. Dr. Deming also taught the Japanese manufacturers that as a company improves its quality, expenses will reduce, and market share will increase [6]. When electric cars first came out of Tesla, Inc., the Japanese were working on hybrids which had two engines: an ICE and an electric motor. This made them heavy.

The story of electric cars is just like that of the bow and arrow industry of old. There were a whole lot of institutions and respected teachers (shifus) in the making of the bows, the strings, the assembling, the shifus to teach the art of shooting (Kung Fu, kalaripayattu etc.) Then someone came up with the gun. People in the long chain of institutions of the bow and arrow industry have vested interest in keeping guns at bay. But when countries that adopted guns started conquering the South despite them knowing how to build it (they had firecrackers), all started adopting guns and cannons. Hybrids are like crossbows.

Today in 2024, there is a heated battle between Internal Combustion Engine (ICE), Battery Electric Vehicle (BEV) and Fuel Cell Electric Vehicle (FCEV) which are running on hydrogen. The ICE industry is linked to the Oil and Gas (O & G) industry [7] because 64% of the output of the O & G industry is used for transportation. If humanity switched to BEV, two huge industries would collapse, the O & G and ICE industries. Today the O & G is still one of the most lucrative industries on earth, making up 3.8% of the world’s economy [8]. In the USA, the bureau of statistics revealed that 118 thousand people work for the O & G industry and generated a revenue of $333 billion, which is a per capita income of $2,822,034 [9]. Therefore, the O & G industry has a lot of capital to delay the advent of other modes of transportation that do not use their products. One option is to use hydrogen, 95% of which is derived from fossil fuels, thereby keeping the O & G industry alive [10]. But CO2 emission from the SMR (steam methane reforming process) produces 9 kg of CO2 per kg of H2. Usually natural gas (70-90% methane) is sent directly into the process chamber and heated with steam. Natural gas got its name in the 1800s to differentiate it from coal gas which is derived from heating coal. Gas that comes out of the ground is termed natural gas. Natural gas, like fossil fuels, is derived from decaying organic matter. The volume it occupies makes it impractical to be used without compressing to Liquified Natural Gas (LNG), unless as in Bintulu, Malaysia where the gas from offshore oil rigs is sent directly into gas turbines (GTs). Similarly, the USA gets 40 % of her electricity from GTs, most of which are powered directly from fracking plants, especially in the Permian Basin in Texas or the Marcellus Shale in Pennsylvania [11].

Today the biggest fight against the BEV is the hydrogen cars, mostly of the FCEV type. This is because the O & G industry knows that humanity is poised to reduce pollution, especially the 56 % of humanity who live in large cities, who do not need to see any CO2 level data. They are constantly breathing and washing the combustion fumes from their bodies and clothes every day [12].

It must be noted that all major industries have long gone electric. The huge trucks in the mines in Australia (where a standing human is only as high as half of the wheel), the largest cranes in the O & G, cranes in ports, trains, the largest prime movers in factories and the prime movers of the largest ships [13].

For example, the Sejinkat Port of Kuching has cranes, two of which were hydraulic and two used electric motors. All four cranes were installed at the same time, but the hydraulic cranes failed very fast while the motor crane has been running since 1987 when the port was built. Motors, especially induction motors designed by Nikola Tesla are robust. A squirrel cage rotor and a stator with copper coils is just too simple to fail. The only source of failure are the bearings and the varnish surrounding the copper coils. But bearing companies, the likes of SKF have perfected it to a high extent over 117 years (since 1907) and copper coil varnish of Class H has been known to enable even large motors to run continually for long spans of time. The induction motor in the Western Digital factory of Kuching has been running the compressor since 1995 (27 years). This induction motor utilizes 600 A per phase, or 1800 A [14].

Prime movers of ships for example must overcome the force of waves of the ocean. ICE is not good at handling sudden changes in the speed caused by the powerful waves. But a simple rotor surrounded by copper coils in the stator can handle it much better.

One of the biggest pros for BEV is that, if each householder has a BEV or many plugged in, they will form a citizen financed backup battery for the electric power grid. When there is a sudden cloud cover over solar farms or a sudden no-wind situation in wind farms, the grid can take power from people’s electric cars.

The above statement is for the average human on earth. But in actuality the power grid will need batteries for more reasons than that. Being a Control Room engineer for the electric power grid of Sarawak, Malaysia, it was noted that engines all over the grid have their accelerator pressed 30 % more than the demand for power. This is called the Spinning Reserve. This is because even if one of the engines in a power station trip, there will be a sudden (millisecond) demand greater than supply situation, causing a sudden greater draw from the stator coils of generators. This will also make them stronger electromagnets which will slow the speed of the rotor which will cause the frequency to drop. The frequency of the voltage wave is the speed of the spinning of the generator stator. Frequency drop is very dangerous. To simplify things, there are three stator coils spaced at 120o apart in the stator of generators (which generate the three phases of power). Actually, there are six coils, each phase coil will make a clockwise turn at one end and an anticlockwise turn at the opposite end and end up in a star point with the other two phases. Therefore, one end is a star point and the other end supplies the load of the country. The rotor is an electromagnet energized with DC. As the rotor’s north pole passes the clockwise coil, its south pole will pass the anticlockwise coil, thereby providing double the current generated in a phase line. The generators generally output at 11 kV – 15 kV but this is then stepped up to 275 kV and is then joined to all other generators in the grid which may be 1000 km away. To join generators in a grid, all generators must be synchronized. Meaning if all are ICE powered generators, if the rotor electromagnet’s north pole is passing the L1 phase coil in one generator, it must pass L1 in all other generators [15].

If the rotor electromagnet’s north pole is passing L1 in one generator and in the second generator, the rotor electromagnet’s north pole is passing L2. In the first generator, the L1 coil will be getting maximum current (voltage wave is at the peak of the sine wave) but the voltage wave will be at the beginning of the negative portion of the sine wave in the second generator. But the two generators are joined with 275 kV wires, therefore there will be a huge explosion due to possibly 300 kV difference between the wires that are joined. This will cause the smaller generator to be blown up. This is why the protocol for generators is that if the frequency of one generator is even slightly different from the others, the protection system will automatically cut it off from the grid and without enough power supplying the demand, the whole grid will trip [15].

To solve this sudden supply and demand inequality, assuming all generators are ICE, they press the accelerator 30 % extra as in the Sarawak Grid (the spinning reserve is 30 % of the grid’s output). Therefore, if one generator in the grid suddenly trips, extra DC is sent to the rotor of other generators and immediately extra current comes out of the stator coils of all the other generators. But this will make the stator coils in all the other generators stronger electromagnets also. But because the accelerator is already being pressed 30 % extra, there is enough mechanical power to overcome the extra magnetic attraction between the stator and rotor coils. Therefore, all generators can still turn at 50 Hz (60 Hz in the USA). But if each householder has BEV or many plugged into the grid, the grid can take power from people’s cars and the Power Utility need not press all the accelerator in all ICE engines 30 % extra all the time [15]. That is an immediate reduction of 30 % climate changing pollution while all other attempts at reducing pollution offer only 1-2 % improvement.

This author studied in SD, USA in the late 1980s and early 1990s and there was an electric plug point at every car park in SD, USA. That was much before the popularization of BEV by Tesla, Inc. The reason why SD needed an electric plug point at every parking spot is because it can get too cold during the deep winters and plug point will power the heater in the car to prevent the fuel and engine oil from freezing. Therefore, humanity has already long developed methods to place an electric plug point in all car parks much before the 1980s. With a plug point in each car parking spot, even if a generator within the grid trips during working hours, the grid can take power from people’s cars which are parked at their workplaces [15].

It must be noted that financial buildings like banks have three power sources, the main supply from the grid, a battery bank and an ICE powered generator. This is because only the battery can immediately cut in upon a grid blackout and keep computers (and therefore financial information) alive. After a while the standby generator will kick in and supply the banks and also recharge the backup batteries. Therefore, battery power output from BEVs will be the fastest backup for the grid.

This is why India, China, Indonesia, Britain, France, and numerous countries have already specified a cutoff date for all vehicles to be BEV. The majority of countries have legislated bans on ICE cars by 2035. Meaning, though there is a severe lack of engineers in politics worldwide, even non-engineer politicians can understand that BEVs can immediately reduce pollution and stabilize the grid [15].

2. Literature Review and current data

William Morrison of the USA developed the first practical electrical vehicle in 1890. People who observed it at the time appreciated that the vehicle did not emit smelly gasoline and exhaust fumes and did not need to be cranked to start [16]. But the invention of the car electric starter in 1912 made ICE engines more attractive for consumers mainly because of the short time to refill gas compared to charging batteries [17]. The vast reserves of oil were coincidently discovered at that time. By the mid-1920s EVs totally lost market share [18]. It was the 1973 oil crisis that got humanity to once again revive EVs. Hybrids were widely sold and appreciated in the later portions of the 20th century [19]. Tesla, Inc played a pivotal role in reintroducing BEV by first getting humanity away from the concept that BEVs are weak vehicles suitable mostly as golf course carts. To achieve this, Tesla Inc. made premium and expensive cars for the rich which depicted that BEVs can be powerful cars. Then many car races of high-end ICE sports cars versus simple BEVs moved humanities’ perception away from the weakness of BEVs.

Tesla, Inc introduced BEVs together with rooftop solar panels which was viewed favorably by people worldwide even though those outside the USA did not experience Tesla’s business as much. It was that vision that changed humanity’s perception of the practicality of BEV. The final anxiety of driving a BEV is being solved as charging infrastructures are being expanded worldwide [20].

There is a very common argument that BEV still uses coal in the power station to produce electricity, but the fact is that even if coal is used to generate electricity, the best pollution control devices can be installed in their chimneys since they have economies of scale. Installing similar pollution controls in each ICE car will make them too expensive for most buyers. In Sarawak, Malaysia for example, there are three coal electricity generating plants namely Sejinkat, Mukah and Belingian, arranged in accordance with the age of the plants. But Belingian has the best pollution control equipment, Mukah has less and Sejinkat has even less.

Typical pollution control in coal plants includes Scrubber Systems to remove SOx and PM (particulate matter). There are also EPSs (electrostatic precipitators which use electric fields to trap ions and therefore capture PM. Then there is SNCR (selective non-catalytic reduction) where ammonia or urea is injected into the exhaust stream to reduce NOx emission. Sound waves are a new concept which can be further developed to control pollution though it is at an infancy today. Powerful sound generators positioned at strategic points in the chimney will be required. Currently they are not developed enough to be well utilized in coal power plants [21].

FCEV requires H2. The SMR (steam methane reforming) process is the primary method of deriving H2. It produces 95% of H2 in use today. Natural gas (which is 70 – 90 % methane or CH4). Initially the natural gas is desulfurized. The desulfurized gas is mixed with water boiled to 700-1000oC in a furnace. Then Ni catalyst is used to achieve the following reaction [22].

$$\mathrm{CH_4\ (g) + H_2O\ (g) \rightarrow CO\ (g) + 3H_2\ (g)}$$

Therefore, the products are a mixture of H2 and carbon monoxide (CO) and some unreacted methane steam. CO is a pollutant, but it can be utilized to derive even more H2 using the process below:

$$\mathrm{CO\ (g) + H_2O\ (g) \rightarrow CO_2\ (g) + H_2\ (g)}$$

This is an exothermic reaction which utilizes the catalyst of CuO or Fe2O3. The eventual mixture still contains H2, CH4 and CO2 plus other trace gasses. A process called pressure swing absorption (PSA) separates the gasses based on their different absorption properties. Membranes are also used to allow H2 to pass through and block the other gasses. The final product is a high purity H2 which is currently mainly used in the manufacture of ammonia for fertilizer and for petroleum refining. The downside is that the whole process described above utilizes a significant amount of heat and releases a significant amount of CO2 unless Carbon Capture and Storage (CSS) is utilized where the CO2 is stored underground mainly to build up pressure in O & G wells to push out more fossil fuels. But of course, in places where there are no O & G wells this is not possible [23].

The other process to derive H2 is via electrolysis of H2O which needs 55 kWh of electricity to produce 1 kg of H2. To get a sense of how much 55000 Wh is, an incandescent light bulb which is switched on for an hour uses 50 Wh. A refrigerator uses 500 Wh if it is switched on for an hour. A toaster which is switched on for an hour uses 700 Wh. Therefore with 55000 Wh a toaster can be switched on for [24]:

$$\frac{55000}{700} = 78\ \text{hours}$$

And that is the power to produce 1 kg of H2 which can provide a H2 car 600 km range. A typical BEV achieves about 6.4 km per kWh. Therefore 55 kWh can provide a range of:

$$55\,\text{kWh} \times 6.4\,\text{km} = 352\,\text{km}$$

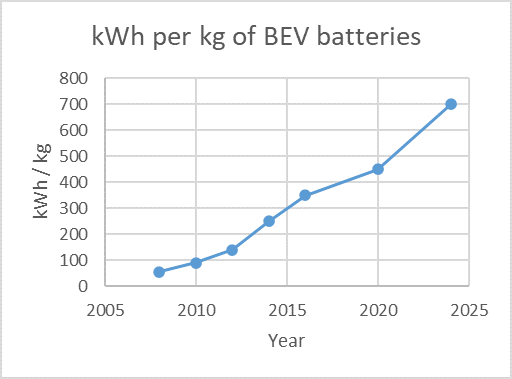

But BEV battery capacity has increased as shown in Figure 1, and cost has come down. From 2008 to 2021, battery cost has decreased by 87 % [25].

BEVs have also saved owners thousands of dollars per year because electricity is cheaper than fuel or hydrogen. BEVs can convert 80% of electrical power from the grid to power the wheels while an ICE only converts about 20 % of the energy of fuel to kinetic energy of the car. And H2 sees energy losses in hydrogen production, storage (compression cost) and then there are losses as it generates electricity in fuel cells which is DC and there are losses as this DC is converted into AC because most FCEV uses AC motors. Using DC motors is not practical because DC motors use carbon brushes which will have to fail one day. Commutator less DC motors where sensors detect the position of the rotor and flip the polarity of DC going into the rotor are to date of small sizes.

Kuching, Malaysia is using hydrogen buses. The expert in that setup informed this author that it takes 1 MW of electricity to generate 20 kg of H2, which is similar to the previous number of 55,000 kWh.

$$\begin{align*}

20\,\text{kg} &\rightarrow 1\,\text{MW} \\

1\,\text{kg} &\rightarrow \frac{1}{20} = 0.05\,\text{MWh} = 50\,\text{kWh} \\

1\,\text{kg} &=

@\,\$0.25\,\text{per}\,\text{kWh}\,(\textit{USA average}) &\Rightarrow 50\,\text{kWh} = 50{,}000 \times 0.25 = \$12{,}500

\end{align*}$$

The H2 is stored in a 1200 kg tank where 50 kg escapes daily because hydrogen is the smallest atom in the universe. Therefore, the daily loss due to H2 escaping from the tank is $625,000.

$$kg = 50\,kg \times \$12{,}500 = \$625{,}000$$

It should be noted that H2 is normally placed in a tank in H2 cars at 700 atm. It takes more energy to compress H2 to 700 atm than the energy it provides to FCEV cars for transportation. That is not counting the high energy and CO2 pollution to derive H2 from natural gas. Humanity is living at 1 atm. A vehicle collision that punctures a 700 atm tank will be disastrous for a lot of humans near the punctured tank.

Countries like Japan and India were initially very interested in H2 because they can finally get out of the control of O & G producing countries since H2O is all around Japan and India. They have therefore invested quite a significant amount of money in producing H2, but it will not go to waste [26]. Large combustion engines can be run with H2. The bigger the combustion engine the more efficient it is because there is more space for the air and fuel to mix. Using H2 to run fuel cells is 200 % more efficient than burning them in a combustion engine [27]. But the problem with the fuel cell’s output is that it is DC which must be converted to AC so that it can be stepped up with a transformer. This must be done to reduce the current in the wires. For example, the main grid wires of 275 kV in Sarawak, Malaysia have current within each cable of which range from 10 A to 59 A while the current coming out of a small car battery upon starting can reach 110 A. Of the four parameters of electric power of P, V, I, R, wire size only depends on I. If transformers are not used, the wires in the main grid will have to be up to 2 m in circumference [28].

A transformer can only step up or down AC. Basically, a transformer can be compared to using a magnet to pass over a wire to generate electricity. If a hand is shaped according to Fleming’s Right-Hand Rule to pass a wire, what the wire will see is a few magnetic field lines when the magnet is far away from the wire, and as the magnet is moved closer to wire, the number of magnetic field lines increases till it reaches a maximum when the magnet is above the wire and then decreases as the magnet moves away from the wire. Basically, the number of magnetic field lines must always change to generate a current in the wire below the magnet. Even if the strongest magnet in the world is placed above a wire, there will be lots of magnetic field lines, but the number of field lines is not changing so there will be no current generated in the wire below it. Therefore, the Fleming Right-Hand Rule with the three fingers is normally defined as F for force or direction of the movement of the magnet, B for the direction of magnetic field, and I for current generated. The F can be changed from Force to varying Field density (still using F). In a transformer, there is no movement, but the AC flowing in the transformer’s primary coil already has a varying Field density because in the far away generator, the rotor moves, passing over the stator coils of the generator. [28]

Therefore, the movement of a magnet across a wire to generate current in the wire is replaced by the movement of the rotor electromagnet across the stator coil wire in a faraway power station. Therefore, as the voltage goes up and down following the sine waveform, there is a varying Field density experienced by the transformer’s secondary coil. The primary and secondary coil is not connected with wires, an iron core which is the best conductor of magnetic field lines (high permeability) moves the field lines from the primary coil to the secondary coil. Note that current is a measure of magnetic field strength of a current carrying wire while voltage is a measure of the electric field strength of a current carrying conductor [28].

If fuel cells are used, the cost of the DC to AC inverters must be considered. It is currently quite highly priced. In fact, the former Energy Secretary of the US, Steven Chu wanted the main grid of the USA to be DC but the cost of the inverters to convert AC to DC was a deterrent [29].

There is also the possibility of using H2 to run GTs. Note the GT which is designed to combust natural gas cannot combust H2 directly. Some modifications must be made but GE Venova and Mitsubishi Heavy Industries have already built GTs that can run with H2. It must be noted that one of the biggest problems with H2 is that it causes embrittlement in metals because it is the smallest atom in the universe and can get into metals and make them brittle. But the insides of GTs are increasingly being changed into ceramics. The ceramics are in the form of tile coatings on metallic components to withstand the high combustion temperature [30].

The cost of building the EV infrastructure is very much cheaper than building fuel stations. A gas station in the US costs between $200,000 to $2,000,000 (taking a median of $1,100,000). But an EV charging station costs $1,676 each (22 kW). Therefore, for the price of one fuel station the number of EV chargers that can be built is [31]:

$$\frac{1{,}100{,}000}{1676} = 656\,\textit{EV charging stations}$$

This is why as of 2024, a single company, Tesla, Inc, has already built 6,000 Supercharger stations in the world (2,300 in N. America, 2,400 in Asia Pacific and 1,100 in Europe). The total number of supercharger stations in all these 6,000 stations is 55,000 [32].

EV batteries are also recyclable with two methods namely pyrometallurgy (high heat treatment) and hydrometallurgy (using chemical solutions) [33].

Therefore, converting the whole O & G plus ICE engine for transportation of humanity to electric vehicles is much more practical because the energy source can be changed anytime, and the infrastructure of EV can remain the same. For example, India is rooting for thorium energy which promises thousands of years of electricity for India given her reserves of thorium. And this can be used to power electric vehicles including planes.

The RMI or the RMI India Foundation (RMIEFI) which conducts research specifically on India’s clean energy transition have predicted that by 2030 EV will form about 74 % of vehicle sales in India. It predicted that ICE cars will peak by 2025 and will experience a free fall after that. By 2027 BEV will be cheaper than ICE cars [34].

The use of renewable energy must be coupled with Artificial Intelligence (AI). Solar panels for example are connected in series. If one panel in the series is covered by a shadow, all the rest in the series will be affected. Similarly in batteries, there are connections in series to get the required voltage and in parallel to get the required charge (or number of hours the battery can supply power). If one battery in a series fails, all batteries in that series will be affected. AI plus contactors at the positive and negative terminal plus one more contactor to jump over that faulty battery can be used to overcome this problem [35].

Toyota’s CEO announced that he was leaving BEV. This is just to justify to his stakeholders that they can all keep their business. The underlying truth is that there are only 20 moving parts in an EV, and the combustion cars have about 30,000 parts which have been made from great grandfather to now with impressive innovation to reach perfection (as Toyota can do best) and all must shut down. That is the loss Toyota is trying to avoid; BEVs are a great disruptor. Of course, the O & G companies / countries will also pay them very well to take this narrative [36].

One more argument against BEV is that it utilizes lots of resources during manufacturing. But studies done have shown that the battery material for an average BEV is 170 kg. While an ICE will use up 17,000 L (12,580 kg) of fuel over its lifetime. If the fuel is filled into tanks, it would be as high as a 90 m building (diesel cars will make a 70 m building). Considering all the material dug from the ground to make a BEV versus an ICE, the cost of the material over its lifetime will be 350 times more for ICE [37].

One of the arguments against BEV is that it emits electromagnetic fields (EMF) which may affect humans. This is most probably a paid argument by the O & G and ICE industries to the medical establishment. The truth is that humans already live in a giant electromagnet. The outer core of the earth is mostly molten iron plus other heavy metals. The earth was initially a spinning ball of gas which was thrown out of the sun, most probably due to some collision of a body with the sun. The force of that collision caused the earth to be in its particular orbit. Initially as the gasses spun, the heavier particles will move out due to centrifugal force, but as more and more particles joined this ball of gas, it acquired the force gravity such that gravity exceeds the centrifugal force, therefore the heavier elements moved to the center of the ball. Therefore, iron and all the heaviest elements in the periodic table moved to the center and the lighter elements like Si and the gasses moved out to the Mantle, Crust and to the atmosphere above earth. Hence the earth has a solid Fe core which is too hot to exhibit any magnetic properties. The outer core, however, has molten Fe and since Fe will always release its valence shell electrons, there are free electrons moving parallel to each other in the outer core. Therefore, just as electrons moving parallel to each in the coils of a solenoid turns it into a magnet, the outer core is a giant electromagnet which creates a force shield around the earth, protecting it from harmful e-m waves from outer space. Therefore, humanity has always lived in a giant electromagnet and need not be concerned by the EMF emitted from the induction motor of an electric vehicle [28].

There are many BEV owners who get much of the power for the car via solar panels. But renewable pathways must be trodden carefully. In the current state, renewal power is causing many problems. States like California and the country of Australia which went heavily into renewals are today facing a power crisis. Backing up a few kW of power due to sudden no wind situation is easy, but when it gets to a few gigawatts, it is nearly impossible. The batteries are not ready today. Only hydro can back it up. But this author believes that criteria is not considered in building large wind farms. A hydro powered generator can energize the grid in 20 seconds. But even a 20 s delay will require sudden tripping of lots of loads (load shedding) in the grid. For some loads like high-tech factories, 20 seconds is enough to damage all products they are making. For a high-tech plant like a chip making plant in Kuching, Malaysia, it takes one month to make one batch of products and that whole batch would be damaged with one power trip.

As mentioned in the introduction, this author was an engineer in the Grid Control Room of the 728 km wide Sarawak Grid. It was his job to call the different power stations to start or stop generators to ensure supply and demand was equal. Table 1 is the time it takes for different types of electric power engines to energize the grid upon getting instructions to start from the Control Room.

Table 1: The time to energize the grid for different types of electric power engines

Coal power station engines | 8 hours |

Gas Turbine engines | 0.75 hour |

ICE engines | 1.25 hour |

Hydroelectric engines | 20 seconds |

The main 275 kV grid wires were continuously observed, if the voltage goes above 275 kV, there is more supply than demand and if it goes below 275 kV, there is more demand than supply. Actions must be taken by starting or stopping generators according to the main grid lines voltage which is 275 kV. Another method used was to energize or de-energize large inductors, called reactors located in substations to bring down or bring up the main grid voltage respectively.

The 20 seconds for a hydroelectric powered generator engine is only if the penstock pipe already has water flowing within it. In this case, energizing a hydro generator requires putting DC into the rotor coils and immediately AC flows out of the stator coils. This span of time to start various generators is the reason why intermittent renewals are not a good idea. Also starting and stopping large ICE, coal or GT plants frequently will damage them. Even ICEs are just kept running for weeks at a time. This may be surprising for most car owners who never keep their cars running for weeks at a time.

Some point to the wind and solar in Western countries, but power projects are so huge that only politicians are high enough to decide on them. This author has seen that. He was in the audience when the energy minister of Malaysia announced she wanted the people of KL to buy 1 GW of solar panels and install it on their roof and supply to the grid. This author wrote a letter to her about the problems with that, which probably ended up in her rubbish bin. If there is a sudden cloud cover over KL as can happen in equatorial Malaysia, there is no way to back up 1 GW. But the Utility manager of KL is not going to lose his job over it. If 1 GW of solar power enters the grid, he is going to run 1 GW of coal as a backup. Therefore, the citizens of KL have to spend a huge amount of money to purchase solar panels and it is being paid for by the Utility as their bills are reduced but the Utility will actually be running 1 GW of coal for this whole political decision.

The only reason humanity is not driving electric cars as much is resistance to electric cars from the O & G plus ICE industries.

3. Maneuverability of BEV

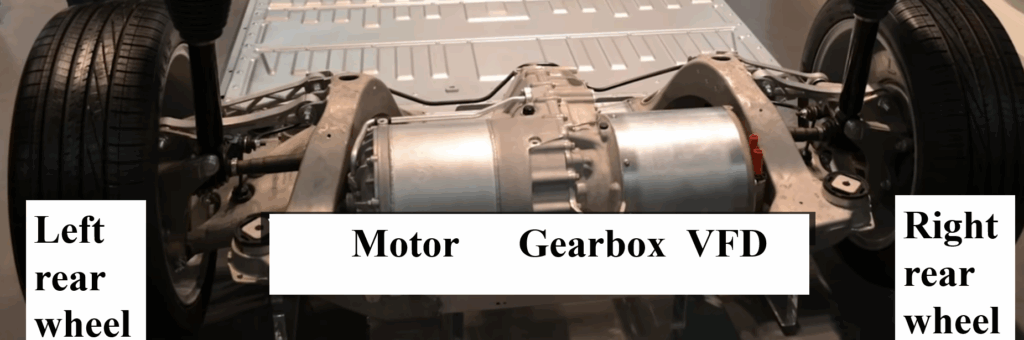

Both the BEV and the FCEV use an induction motor as the prime move for the wheels. Therefore, the BEV is built like a skateboard with a flat base which is the battery compartment and four wheels. There are only two cylinders that run the whole car, one is the induction motor whose shaft is connected directly to the shaft of the rear wheels. The other cylinder is the Variable Frequency Drive (VFD). In between the two is a gearbox as shown in

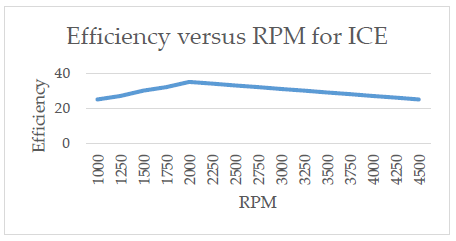

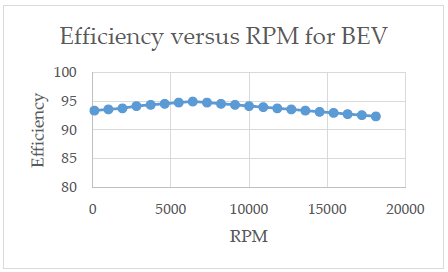

The VFD is basically a computer that has software that replaced many mechanical systems in the car. It makes the AC waves going into the induction motor narrower (smaller wavelength) to get the car to move faster and make the AC sine wider (bigger wavelength) to get the motor to go slower. If the amplitude of the sine wave is higher, the car will have more power. The gearbox is just a simple open differential. The differential was developed from the days of the horse cart. The four wheels of a horse cart are independent. But when an ICE was first used to drive a cart, the cart cannot turn because to turn, the outer diameter wheel needs to move faster. Therefore, a differential was invented to enable the outer diameter wheel to move faster than the inner diameter one. The gearbox of a BEV just reduces the speed two times from the speed of the induction motor; this also provides more power to the car. Fig. 3 and Fig. 4 shows that BEV is powerful at a wide range of speed while an ICE is only powerful at a particular speed.

4. Conclusion

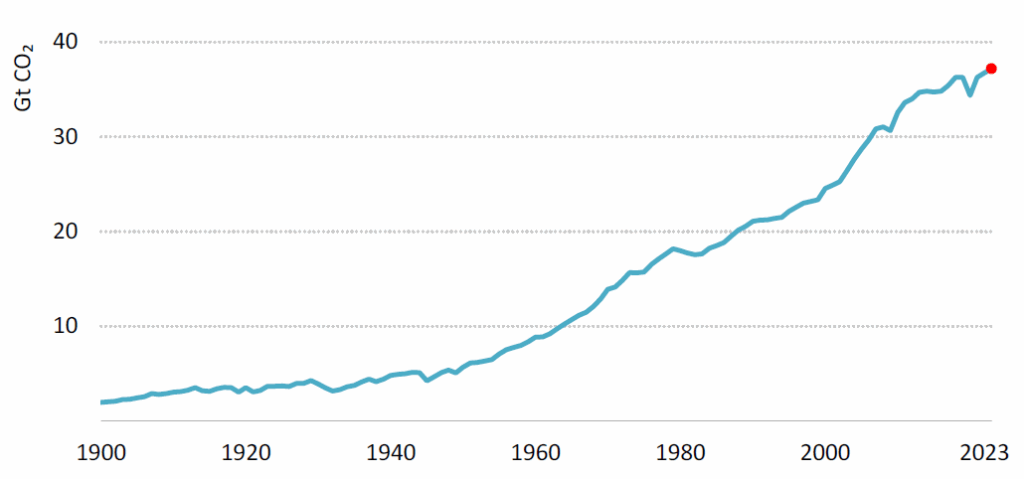

The conclusion of this work is that the argument against the BEV is just a fear of business loss from the O & G and ICE industries. The leaders of the old system, as for old kingdoms which still have much power, do not want to lose hold of their power. They could just use their huge financial resources to move into the BEV and other industries but their vested interest in the O & G and ICE is just too great. It is not just a change in technology, the mindset and expertise must change to get into BEV. They prefer to fight the introduction of BEV. BEV is capable of immediately clearing up pollution from the biggest cities of earth where 56 % of humanity lives. BEV is also very useful to keep the integrity of the electrical power grid including creating a large energy saving and pollution reduction (up to 30 %) for the electric power grid. It must be noted that the electric power grids of the earth are currently the biggest polluter of earth. The second biggest polluter is transportation (motorcycles, cars, trucks, trains and planes). Together these two industries produced 37 billion tonnes (Gt) of CO2 in 2023. Power production emits 33 % of CO2 pollution and the transportation industry emits 24 % of pollution emitted [40]. This paper explains how CO2 pollution can be reduced from both these sectors with the widespread usage of BEV. Fig. 5 is a picture that tells a thousand words which depict what humanity needs to do.

Conflict of Interest

The authors declare no conflict of interest.

- R. D. Reitz, “Directions in internal combustion engine research,” Combustion and Flame, vol. 160, no. 1, 1-8, Jan. 2013, doi: 10.1016/j.combustflame.2012.11.002.

- H. N. Gupta, Fundamentals of Internal Combustion Engines. PHI Learning Pvt. Ltd., 2012, ISBN: 978-81-2023-4680-2.

- M. S. Jneid, P. Harth, and P. Ficzere, “In-wheel-motor electric vehicles and their associated drivetrains,” International Journal for Traffic and Transport Engineering, vol. 10, no. 4, 415-431, 2020, doi: 10.1109/TIA.2015.2399617.

- M. B. Neeraja, Electric Vehicles. Academic Guru Publishing House, 2023, ISBN: 978-81-967548-1-5.

- R. Pradhan, N. Keshmiri, and A. Emadi, “On-board chargers for high-voltage electric vehicle powertrains: Future trends and challenges,” IEEE Open Journal of Power Electronics, 2023, doi: 10.1109/OJPEL.2023.3251992.

- W. M. Tsutsui, “W. Edwards Deming and the origins of quality control in Japan,” Journal of Japanese Studies, vol. 22, no. 2, 295-325, 1996, doi: 10.2307/132975.

- J. D. Hunt, A. Nascimento, N. Nascimento, L. W. Vieira, and O. J. Romero, “Possible pathways for oil and gas companies in a sustainable future: From the perspective of a hydrogen economy,” Renewable and Sustainable Energy Reviews, vol. 160, p. 112291, 2022, doi: 10.1016/j.rser.2022.112291.

- M. A. Raji, H. B. Olodo, T. T. Oke, W. A. Addy, O. C. Ofodile, and A. T. Oyewole, “Real-time data analytics in retail: A review of USA and global practices,” GSC Advanced Research and Reviews, vol. 18, no. 3, 059-065, 2024, doi: 10.30574/gscarr.2024.18.3.0089.

- M. Amiti and S. Heise, “U.S. market concentration and import competition,” The Review of Economic Studies, 2024, doi: 10.1093/restud/rdae045.

- R. Vezzoni, “How ‘clean’ is the hydrogen economy? Tracing the connections between hydrogen and fossil fuels,” Environmental Innovation and Societal Transitions, vol. 50, p. 100817, 2024, doi: 10.1016/j.eist.2024.100817.

- M. J. Bradshaw and T. Boersma, Natural Gas. John Wiley & Sons, 2020, doi: 10.1111/1365-2745.14264.

- C. Fletcher, W. J. Ripple, T. Newsome, P. Barnard, K. Beamer, A. Behl, … and M. Wilson, “Earth at risk: An urgent call to end the age of destruction and forge a just and sustainable future,” PNAS Nexus, vol. 3, no. 4, p. pgae106, 2024, doi: 10.1093/pnasnexus/pgae106.

- P. Karunakaran, M. S. Osman, V. Karuppanna, S. C. Cheng, M. D. Lee, M. D. Fadhilah, and A. K. S. Lau, “Eddy Current versus Joule Heating Effects for a Cable Suspended in an Iron Pipe,” IEEE Xplore, 2021, doi: 10.1109/INOCON50539.2020.9298438.

- P. Karunakaran, M. S. Osman, V. Karuppanna, S. C. Cheng, M. D. Lee, A. Richard, and A. K. S. Lau, “Electricity Transmission Under South China Sea by Suspending Cables Within Pipes,” 2020 International Conference for Emerging Technology (INCET), Aug. 2020, doi: 10.1109/INCET49848.2020.9154119.

- P. Karunakaran, Electrical Power Simplified. AuthorHouse, 2018, ISBN: 978-1-5462-6246-6.

- R. Bhardwaj and S. Gupta, “Evolutionary progress of the electric car market with future directions,” in Latest Trends in Renewable Energy Technologies: Select Proceedings of NCRESE 2020, Springer Singapore, 2021, 315-321, doi: 10.1007/978-981-16-1186-5_27.

- N. Burton, History of Electric Cars. The Crowood Press Ltd., 2013, ISBN: 978-1-84797-571-3.

- D. S. Painter, “Oil and the American Century,” Journal of American History, vol. 99, no. 1, 24-39, Jun. 2012, doi: 10.1093/jahist/jas073.

- M. E. Staub, “Snake Oil and Gaslight: How the Petroleum Industry Got in Touch with Nature,” Environmental Humanities, Duke University Press, vol. 15, no. 2, 85-104, 2023, doi: 10.1215/22011919-10422300.

- D. Ronanki, A. Kelkar, and S. S. Williamson, “Extreme fast charging technology—Prospects to enhance sustainable electric transportation,” Energies, Electric Mobility and Transportation Innovation (E-MOTION) Laboratory, Smart Transportation Electrification and Energy Research (STEER) Group, vol. 12, no. 19, p. 3721, 2019, doi: 10.3390/en12193721.

- J. A. Gallego-Juárez, E. Riera-Franco De Sarabia, G. RodrÍguez-Corral, T. L. Hoffmann, J. C. Gálvez-Moraleda, J. J. RodrÍguez-Maroto, … and M. Acha, “Application of acoustic agglomeration to reduce fine particle emissions from coal combustion plants,” Environmental Science & Technology, vol. 33, no. 21, 3843-3849, 1999, doi: 10.1021/es990002n.

- M. Garg, D. Gera, A. Bansal, and A. Kumar, “Generation of electrical energy from sound energy,” in 2015 International Conference on Signal Processing and Communication (ICSC), 2015, 410-412, doi: 10.1109/ICSPCom.2015.7150687.

- Y. Bai and M. F. Cotrufo, “Grassland soil carbon sequestration: Current understanding, challenges, and solutions,” Science, vol. 377, no. 6606, 603-608, 2022, doi: 10.1126/science.abo238.

- A. Chunekar and A. Sreenivas, “Towards an understanding of residential electricity consumption in India,” Building Research & Information, vol. 47, no. 1, 75-90, 2019, doi: 10.1080/09613218.2018.1489476.

- S. Vengatesan, A. Jayakumar, and K. K. Sadasivuni, “FCEV vs. BEV—A short overview on identifying the key contributors to affordable & clean energy (SDG-7),” Energy Strategy Reviews, vol. 53, p. 101380, 2024, doi: 10.1016/j.esr.2024.101380.

- S. K. Kar, A. S. K. Sinha, S. Harichandan, R. Bansal, and M. S. Balathanigaimani, “Hydrogen economy in India: A status review,” Wiley Interdisciplinary Reviews: Energy and Environment, vol. 12, no. 1, p. e459, 2023, doi: 10.1002/wene.459.

- Z. Stępień, “A comprehensive overview of hydrogen-fueled internal combustion engines: Achievements and future challenges,” Energies, vol. 14, no. 20, p. 6504, 2021, doi: 10.3390/en14206504.

- P. Karunakaran, Electrical Power Simplified. UTS Publishers, 2023, 243 pages, ISBN: 978-629-98726-2-7.

- E. Hand, “Newsmaker of the year: The power player,” Nature, vol. 462, 978–983, 2009, doi: 10.1038/462978a.

- P. Chiesa, G. Lozza, and L. Mazzocchi, “Using hydrogen as gas turbine fuel,” Journal of Engineering for Gas Turbines and Power, vol. 127, no. 1, 73-80, 2005, doi: 10.1115/1.1787513.

- A. C. Lusk, X. Li, and Q. Liu, “If the Government Pays for Full Home-Charger Installation, Would Affordable-Housing and Middle-Income Residents Buy Electric Vehicles?,” Sustainability, vol. 15, no. 5, p. 4436, 2023, doi: 10.3390/su15054436.

- Y. Babar and G. Burtch, “Recharging Retail: Estimating Consumer Demand Spillovers from Electric Vehicle Charging Stations,” Manufacturing & Service Operations Management, 2024, doi: 10.1287/msom.2022.0519.

- Y. Kotak, C. Marchante Fernández, L. Canals Casals, B. S. Kotak, D. Koch, C. Geisbauer, and H. G. Schweiger, “End of electric vehicle batteries: Reuse vs. recycle,” Energies, vol. 14, no. 8, p. 2217, 2021, doi: 10.3390/en14082217.

- A. B. Styczynski, “Business Model Innovations for Electric Vehicle Adoption in India: An Ecosystem Perspective,” in India’s Energy Revolution, Routledge India, 2024, 190-213, ISBN: 9781003281818.

- P. Karunakaran, P. Karunakaran, S. Karunakaran, A. Karunakaran, F. Cassidy, V. Karuppan, and S. Haridas, “The Optimization of Solar Photovoltaic System for Rural Off-grid Villages,” IEEE Xplore, 2022, doi: 10.1109/ICONAT53423.2022.9725993.

- D. Keohane, et al., “‘Told you so’ moment for Toyota on hybrids. Carmaker enjoys measure of vindication after warning repeatedly that consumers would balk at going full electric,” Financial Times, p. 9, 27 Feb. 2024. [Online]. Available: link.gale.com/apps/doc/A784128571/AONE?u=anon~7503423a&sid=googleScholar&xid=9740b1f3. Accessed: 26 June 2024.

- A. F. Burke, J. Zhao, and L. M. Fulton, “Projections of the costs of light-duty battery-electric and fuel cell vehicles (2020–2040) and related economic issues,” Research in Transportation Economics, vol. 105, p. 101440, 2024, doi: 10.1016/j.retrec.2024.101440.

- M. Kumar, K. P. Panda, R. T. Naayagi, R. Thakur, and G. Panda, “Comprehensive Review of Electric Vehicle Technology and Its Impacts: Detailed Investigation of Charging Infrastructure, Power Management, and Control Techniques,” Applied Sciences, vol. 13, no. 15, p. 8919, 2023, doi: 10.3390/app13158919.

- G. Carrington and J. Stephenson, “The politics of energy scenarios: Are International Energy Agency and other conservative projections hampering the renewable energy transition?,” Energy Research & Social Science, vol. 46, 103-113, 2018, doi: 10.1016/j.erss.2018.07.011.

- S. Paul and R. N. Bhattacharya, “CO2 emission from energy use in India: a decomposition analysis,” Energy Policy, vol. 32, no. 5, 585-593, 2004, doi: 10.1016/S0301-4215(02)00311-7.

- Prashobh Karunakaran, Mohammad Shahril Osman, “A Cloud-Native Decision Intelligence Architecture for Sustainable CPG Supply Chain Networks “, Journal of Engineering Research and Sciences, vol. 5, no. 1, pp. 35–45, 2026. doi: 10.55708/js0501004

- Prashobh Karunakaran, Mohammad Shahril Osman, “Green Tariffs as Market Accelerators for Corporate Renewable Energy Adoption: A Comprehensive Review of U.S. Programs and their Impact on C&I Decarbonization “, Journal of Engineering Research and Sciences, vol. 4, no. 8, pp. 1–17, 2025. doi: 10.55708/js0408001

- Prashobh Karunakaran, Mohammad Shahril Osman, “Linking Consumer Innovativeness to the Cryptocurrency Intention: Moderating Effect of the LOHAS (Lifestyle of Health and Sustainability) Lifestyle”, Journal of Engineering Research and Sciences, vol. 1, no. 12, pp. 1–6, 2022. doi: 10.55708/js0112001

- Prashobh Karunakaran, Mohammad Shahril Osman, “CRESustain: Approach to Include Sustainability and Creativity in Requirements Engineering”, Journal of Engineering Research and Sciences, vol. 1, no. 8, pp. 27–34, 2022. doi: 10.55708/js0108004

- Prashobh Karunakaran, Mohammad Shahril Osman, “Prakriti: A Gamified Approach to Saving Water “, Journal of Engineering Research and Sciences, vol. 1, no. 2, pp. 33–40, 2022. doi: 10.55708/js0102004