Advanced Digital Twin of a Industrial Robotic System for Measuring Pipe Wall Thickness in Nuclear Power Plants

Journal of Engineering Research and Sciences, Volume 3, Issue 12, Page # 14-23, 2024; DOI: 10.55708/js0312002

Keywords: Digital Twin, Ultrasound Measurement, Pipe Wall Thickness, Virtual Commissioning, Process Simulate

(This article belongs to the Special Issue on SP5 (Special Issue on Multidisciplinary Sciences and Advanced Technology 2024) and the Section Robotics (ROB))

Export Citations

Cite

Vitalli, R. A. P. and Moreira, J. M. L. (2024). Advanced Digital Twin of a Industrial Robotic System for Measuring Pipe Wall Thickness in Nuclear Power Plants. Journal of Engineering Research and Sciences, 3(12), 14–23. https://doi.org/10.55708/js0312002

Rogério Adas Pereira Vitalli and João Manoel Losada Moreira. "Advanced Digital Twin of a Industrial Robotic System for Measuring Pipe Wall Thickness in Nuclear Power Plants." Journal of Engineering Research and Sciences 3, no. 12 (December 2024): 14–23. https://doi.org/10.55708/js0312002

R.A.P. Vitalli and J.M.L. Moreira, "Advanced Digital Twin of a Industrial Robotic System for Measuring Pipe Wall Thickness in Nuclear Power Plants," Journal of Engineering Research and Sciences, vol. 3, no. 12, pp. 14–23, Dec. 2024, doi: 10.55708/js0312002.

This paper presents the development of the digital twin of an advanced industrial robotic system for pipe wall thickness inspection in the turbine building of nuclear power plants. The robotic inspection system consists of 3 units, the first being the mobile unit, the second a robotic unit for automatic pipe wall thickness measurement using the ultrasound technique, and the third unit for power supply, communication and auxiliary services. To develop the advanced robotic inspection system, a prototype was built in the laboratory to study different situations and geometric configurations that may arise in the field (turbine building). With Process Simulate software version 16.1.2, the digital twin of the prototype was developed including industrial robot, metal platform and pipe sections. This paper presents the results for the virtual commissioning of the wall thickness measurement of a vertical pipe section and the novel design of the End-Effector of the industrial robot. Therefore, technical discussions are made on the requirements to deal from the design to the functional requirements of developing the end-effector, digital twin and the creation of a commissioning method for industrial robots. The analyses and insights from virtual commissioning made it possible to verify that the robot could access any part of the pipe surface through interpolated movements with spatial coordinates of the robotic arm along its sides.

1. Introduction

Complex industrial facilities such as nuclear power plants require pipe wall thickness inspection for safe and reliable operation. These pipes, submitted to high pressure and temperature, connect the steam generators, turbine, condenser, and may undergo thickness reduction due to corrosion and erosion [1]-[3]. The inspection environment is hot and humid (50oC and 100 % relative humidity). The field space has complicated geometry and access to inspection locations, the pipes have diameters varying from 50 cm to 65 cm, and are positioned in horizontal, vertical, or inclined directions. During plant panned shutdown, the inspections may include tens of thousands measurement points of wall thickness [4], [5].

Traditional inspection systems are usually rigid and require intense human action to circumvent field unforeseen scenarios to make wall thickness measurement. Given the amount of work involved during inspections, it is desirable to automate these activities, and foresee access difficulties and variability of inspection conditions and pipes geometric configurations. To increase the efficiency to handle complex activities in changing scenarios, several authors propose the use of robotic automation systems with and without user assistive actions [6]-[8], and the use of digital twins and other industry 4.0 approaches to streamline their design and commissioning phases [9].

This work presents part of the development of a robotic system for measuring the wall thickness of the secondary

system pipes of the Angra 1 nuclear power plant, more specifically the development of its digital twin. This method allows dividing the development process into two stages, the first being development via simulation (virtual project) and the second stage in which the physical project is built from the virtual project data, including the robot programming that is exported from the virtual project to the field robot [10].

Digital twins are very realistic virtual models of a process and its interaction with the actual world environment [11]. They include the equipment and all the steps to carry out a certain production process [12]. Using the benefits of the digital twin and virtual commissioning tools, it is possible to increase communication and coordination between the parts of the process, allowing for smarter decision-making [12]. This technology makes it possible to quickly and flexibly develop different situations aimed at automating and integrating operator agents and robes to perform complex tasks [13]. It allows integrating sensory data from physical assets and simulating a variety of robotic conditions in which an agent can interact. As a result, the agent can learn an adaptive task allocation strategy that increases project performance. In [13], the authors tested this method for the robot-automated construction problem. Results indicated that model task allocation reduced build time by 36% in three dynamic test environments when compared to the conventional method.

The biggest benefit of virtual commissioning is the savings. It is possible to test an investment in advance, which could be hundreds of thousands or even millions of dollars in equipment, since a single robot could cost you around $50 to $70,000. [14]. So, five robots, equipment, clamp systems, accessories, different products, and all that together in one manufacturing cell is a significant investment. Companies do not intend to develop projects without knowing if it can satisfactorily perform at the expected levels and results. Process reduction Standard operating. Possibility of carry out part of this process in a more convenient environment (no necessarily on-site) combined with the opportunity to use the emulation model for training workers. Parallel development and optimization of mechanical parts, especially mechanisms mechatronics. [15]. Programming and debugging simultaneously from the control software. The Companies aim to implement sustainable manufacturing of robotic cells, in order to improve profitability, reducing resource consumption, global expenses, as well as satisfying the regulatory input of ecological impacts. In addition, the widespread adoption of industrial robots, necessary to satisfy the ever-increasing requirements in terms of manufacturing quality, customization and flexibility, further increased the need to improve the energy efficiency of robotic cells. [16].

This article is organized as follows: section 2 presents a State of Art, section 3 presents a brief description of the robotic system for pipe wall thickness measurement and section 4 presents the method used in this research, data and details of the equipment used. In section 5 we present the results and discussions and in section 6, the final considerations.

2. State of Art

This paper seeks to present, through emerging projects, the concept of digital twins was named one of Gartner’s Top 10 Strategic Technologies Trends for 2022 [17]. Thomas Kaiser, SAP Senior Vice President, IoT, put it this way: “Digital twins are becoming a business imperative, covering the entire lifecycle of an asset or process and forming the basis for connected products and services. Companies that fail to respond will be left behind.” It is estimated that within three to five years, billions of things will be represented by digital twins [18]. Using physical data about how a thing’s components operate and respond to the environment, as well as data provided by sensors in the physical world, a digital twin can be used to analyze and simulate real-world conditions, respond to changes, improve operations, and add value. Industry 4.0 (i4.0), which has been known as the “Fourth Industrial Revolution”, emerges with the aim of meeting this new global demand with customized products and services [19]. One of the concepts that will be widely used in i4.0 is the Digital Twin, which from a production perspective, incorporates the virtual context into the real context of a production system. In [20], Digital Twins are very realistic virtual models of the current state of the process and its own behavior in interaction with the real-world environment, including the equipment and all the steps to carry out a given production process [21], [22]. Using the benefits of the digital twin (DT) and virtual commissioning (VC) tools, it is possible to increase the advantage of communication and coordination between manufacturing areas, allowing for smarter decision-making. This allows automated systems and robotic cells to start operating (running) much faster and with fewer errors [23].

According to [24], the growing use of Virtual Commissioning during the development process of automated factories, combined with the growing demand for better quality control, leads to the need for improved virtual plants that systematize the configuration procedures required to perform their processes. Common plant simulation techniques based on the concept of virtual commissioning of robotic cells go beyond the need to validate control algorithms. In other words, new approaches need to be developed to meet the demand for reconfiguring their operational resources in a systematic way, compatible with the flexibility that these autonomous resources currently have. The need for new solutions in Robotics Engineering® for the design of complex projects involving physical systems and the virtual part associated with them has never been so present. Virtual commissioning technology can be considered as one of the established trends in automotive assembly. Among other benefits, it promotes more efficient treatment of the complexity associated with assembly systems, capable of causing a reduction in the acceleration time of the system itself and a reduction in the development time of the product capable of meeting market competitiveness.

According to [25], the digital twin synthesizes sensory data from physical assets and is used to simulate a variety of robotic construction site conditions in which an agent may interact. As a result, the agent can learn an adaptive task allocation strategy that increases project performance. They tested this method with a case project in which a virtual robotic construction project (i.e., interlocking concrete bricks are delivered and assembled by robots) was digitally twinned for training. The results indicated that the model task allocation reduced construction time by 36% in three dynamic test environments when compared to an imperative model rule-based method.

Along with the trends of mass customization, flexible robotic applications are becoming increasingly popular. Although conventional robotic automation of workpiece handling seems to have been solved, advanced tasks still require a lot of effort to achieve. In most cases, on-site robot programming methods, which are intuitive and easy to use, are not applicable in flexible scenarios. On the other hand, the application of offline programming methods requires careful modeling and planning. Consequently, [26] proposes a generalized approach to the development methodology for flexible pick-and-place robotic work cells in order to provide guidance and thus facilitate the development process. The methodology is based on the Digital Twin (DT) concept, which allows iterative refinement of the work cell in both the digital and physical space. The goal is to streamline the overall commissioning (or reconfiguration) process and reduce the amount of work in the physical work cell. This can be achieved by digitizing and automating the development and maintaining sufficient proximity. With this, the operation of the digital model can be performed accurately in the physical work cell. The methodology is presented through a semi-structured pick-and-place task, performed in an experimental robotic work cell in conjunction with a reconfiguration scenario [27]-[28].

3. Brief Description on of the Advanced Robotics System

The Robotic System for pipe wall Thickness Measurement (RSTM) aims to meet the licensing needs of the Angra 1 Nuclear Power Plant for long-term operation in fast and efficient manner [29]. This RSTM has 3 units, the first, named Unit of Remotely Operated Vehicle (UROV), being a vehicle that can be operated remotely to allow displacement of the whole RSTM to the pipe area under inspection. The second unit, named Unit of Measuring Robotic Cell (UMRC), is a robotic work cell indexed on the UROV and equipped with a robotic arm that performs the movements and inspection actions and an effector with sensors for spatial orientation and for measuring pipe wall thickness through the ultrasound technique. The third unit contains all other RSTM systems such as power supply cables, data transmission cables, real-time information, computer, and ancillary equipment. This unit is named Unit of Communication, Power supply and Ancillary services (UCPA) [29].

The RSTM must be able to approach the defined inspection location and measure the thickness of the pipe wall. Figure 1 shows the complexity and geometric variability of the piping system in the field (turbine building). The solution provided for the inspection problem is a hybrid, contemplating the assistance action of the user to approach the inspection region, and robotic automation to perform the final approach to the inspection locations on the pipe surface and wall thickness measurements. An example of actual inspection locations is the grid of yellow circles shown in Fig. 1. The robot end-effector has an ultrasound-based approximation sensor to provide spatial orientation and an ultrasound-based sensor for pipe wall thickness measurement [30].

The user operates the UROV to approach the RSTM to the measuring locations on the pipe external surface. The first grid location must be manually identified and recorded by the user, that is, with the help of the “teach pendant” he or she moves the industrial robot end-effector through the piping environment to the first measurement position marked on the pipe wall and register its coordinates. From there, the robot present in the UMRC, with its spatial orientation system, automatically scans all the measuring points on the grid and automatically performs the wall thickness measurements. After carrying out the measurement, the result must be transmitted to the UCPA through the communication interface with the plant.

While conventional robotic automation for handling workpieces and performing specific tasks seems to have been resolved, more complex tasks in less controlled environments, such as in the field, require more flexible solutions. In most cases, robot programming methods in a controlled environment are not applicable in variable scenarios found in the real world [31].

4. Methods, Data and Equipment

The use of the Digital Twin concept in an iterative way, both in the digital space and in the physical space, to refine the work cell development process is the solution adopted in this work. The objective is to streamline the overall commissioning process with different configurations or reconfigurations according to the work situation [31]-[32].

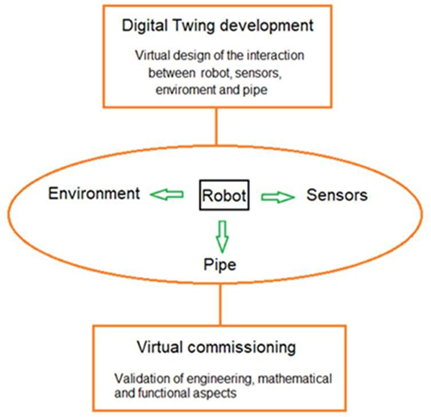

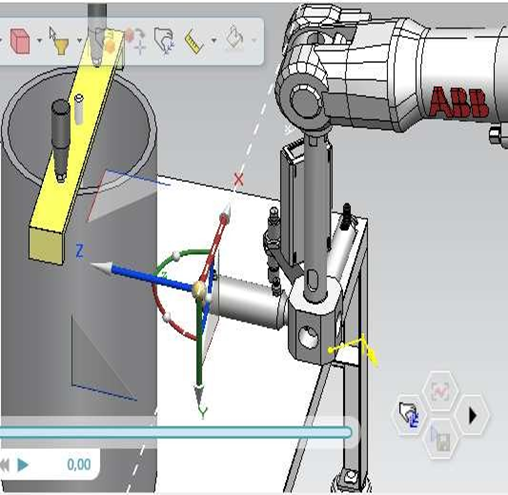

Figure 2 presents the main steps of the approach based on the digital twin technique for the UMRC development. The software adopted to develop the digital twin is the Tecnomatix Process Simulate, version 16.1.2 and the robot used is the ABB IRB 1600-6/1.45 model.

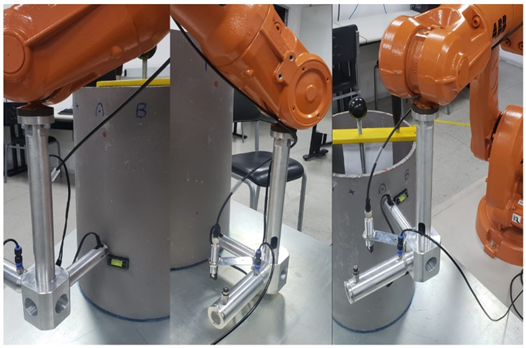

Figure 3 shows the robotic cell prototype installed at the UFABC Robotics Laboratory to develop the UMRC that contains the intelligent part of the robotic measurement system. The robotic cell includes ABB IRB 1600-6/1.45 robot, the metal platform and two pipe sections taken from the Angra 1 nuclear power plant. The pipe section is assembled on the platform in different geometric configurations and situations emulating actual measurement conditions. These configurations are obtained from field situations like the one shown in Figure 3 or others from field situations as shown in Figure 1.

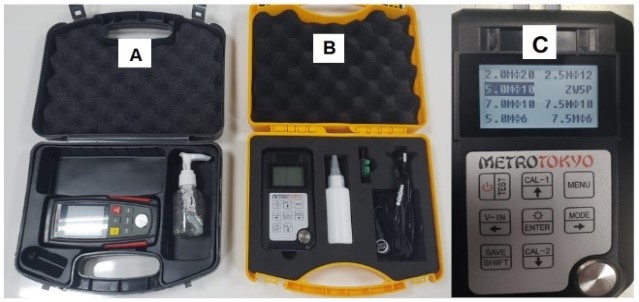

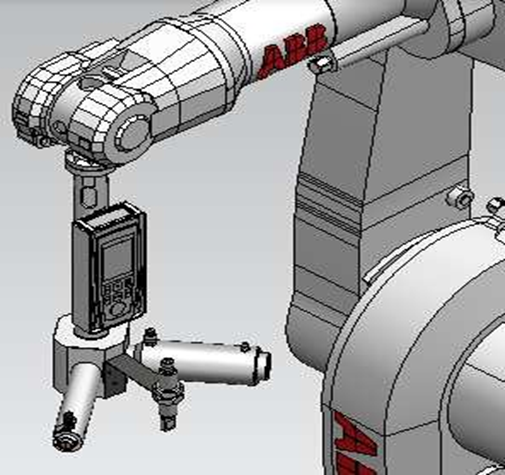

Automatic measurement was performed numerous times using various measurement techniques to ensure repeatability, accuracy and robustness of the measured data. The ultrasonic thickness gauge from the manufacturer METROTOKYO used was the MTK-1301 PRIME model. The electronic transducer was the standard 5MHz/Ø10mm model. The longitudinal wave speed for the “glycerin” material was 1920 m/s and for the 330-steel material it was 5600 m/s, respectively, the speed of sound. Figure 4 shows the specification of the system’s measuring sensors.

The older model did not allow data extraction, as it did not have a USB connection. Therefore, the MTK-1301 PRIME meter model was used, with the following features:

- Manual or automatic shutdown after a period of non-use;

- Table of 9 pre-established ultrasound speeds;

- Calibration function with 3mm standard attached to the meter;

- Calibration of the speed of sound with 1 or 2 points;

- Simple or sweep measurement;

- Individual measurement or with average calculation;

- Measurement with audible alarm for minimum/maximum tolerance;

- Measurement with differential calculation with percentage;

- Measurement on a surface with high temperature (optional sensor);

- Improved measurement for pipe walls. measurement

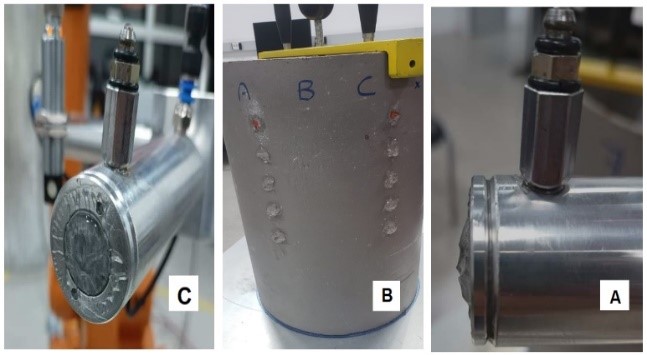

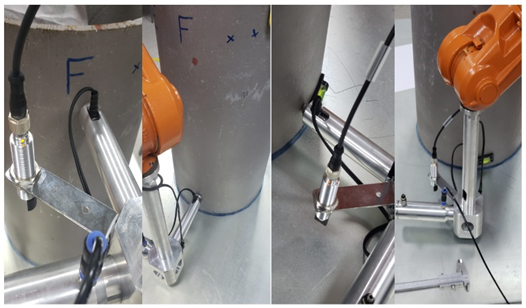

Figure 5 shows evidence of the unprecedented procedure developed in the laboratory for applying the coupling liquid. It was observed through numerous tests that a small amount of coupling liquid (glycerin) interferes with the quality of the measurement, that is, there are chemical reactions between the electronic transducer nozzle, the type of pipe material and the amount of glycerin. The measurements remained stable with two sprays per point and the robotic manipulator program was adjusted for this function through the “pulse” command.

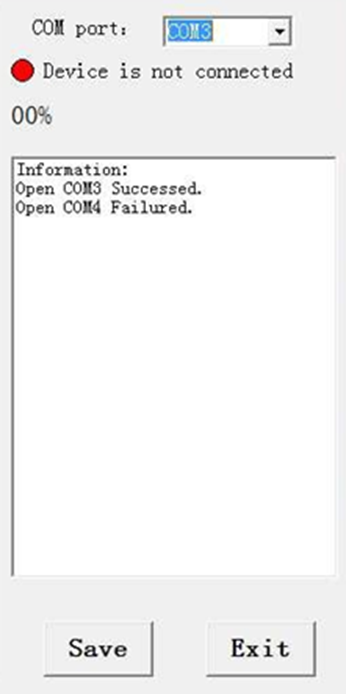

The Communication, Power Supply and Ancillary Services Unit (UCPA) fulfilled the scope of its title. For the communication part, the principles of Industry 4.0 were adopted, which seeks to integrate the “work field”, the engineering group and other sectors that Eletronuclear may require. After the thickness measurement was performed, the result was transmitted to the UCPA through a communication interface. These enabling technologies of Industry 4.0 follow data security and interface communication protocols based on APIs (Application Programming Interface) that allow applications to be customized according to Eletronuclear’s needs. The UCPA was created and developed based on a new, more modern thickness gauge model that allowed access and transfer of the measured data that was stored inside the gauge to an external computer. Figure 7 and Figure 7 shows both systems.

5. Results and Discussions

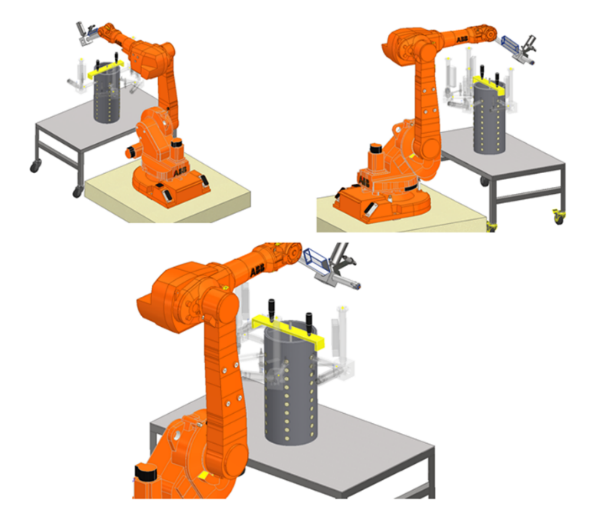

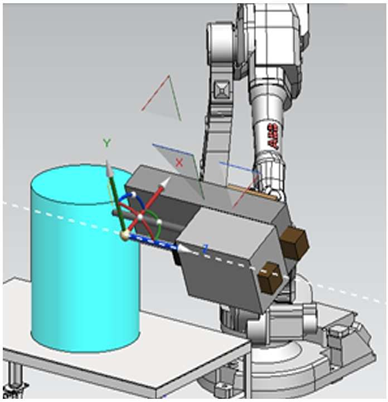

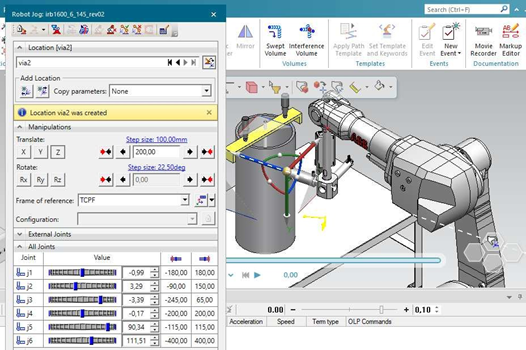

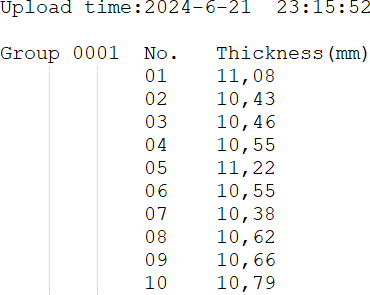

The workstation geometric data representing the UMRC prototype (Figure 3), containing information about the robot, workstation platform, piping section and sensors, were transferred to the Process Simulate software. After modeling the UMRC prototype digital twin with all its physical characteristics (ABB IRB 1600-6/1.45 robot and end- effector), mathematics, kinematics, and information from the environment, virtual commissioning began in order to test and validate the prototype solution for building the robotic cell. Figure 4 presents the UMRC prototype digital twin developed with Process Simulate software for the configuration of a pipe section with vertical orientation. The two boxes connected at the end of the robotic arm represent volumes occupied by the end-effector. Table 1 presents the positioning of the robotic arm for a thickness measurement activity performed during virtual commissioning. It shows the positioning in terms of the angles from the 6 joints of the robot’s digital twin at the measurement location indicated in Figure 8.

Virtual commissioning was performed for various locations of wall thickness measurement in this vertical pipe section ensuring that the robot could accesses any part of the pipe external surface and perform measurements. Accesses were verified by moving the robotic arm along the sides of the pipe. The result in Table I exemplifies a measurement location accessed by the robot’s digital twin.

Table 1: Angles for the joints furnished by the digital twin of robot ABB IRB 1600-6/1.45. The joint angles represent a measuring position on the pipe section shown in Figure 8.

Joint | Angle (degree) |

j1 | 37.45 |

j2 | 2.98 |

j3 | 37.70 |

j4 | 71.51 |

j5 | 36.32 |

j6 | 141.12 |

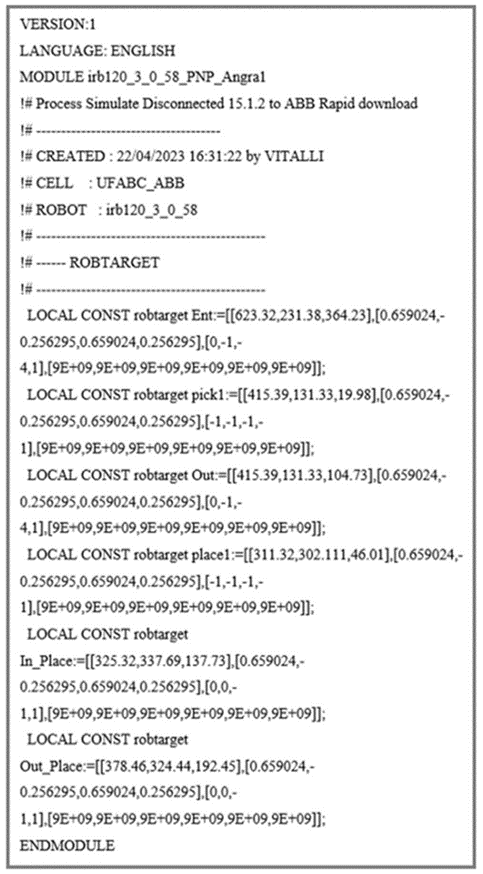

Figure 8a presents the OLP program generated by Process Simulate for export to the real robot ABB IRB 1600-6/1.45.

The success of automatic measurements with robotic technology was guaranteed by the innovation in the development of the automatic “spraying” process of the coupling liquid (glycerin). This accessory present in the robot’s End-Effector was essential to spray the ideal amount of glycerin before the electronic transducer accurately measured the thickness at the point. It was configured and activated by the robot’s control logic through a solenoid valve in conjunction with a unidirectional flow regulator to automatically control the output pressure within a range of 2.4 bar (Kgf/cm2). The ultrasonic sensor that accurately measures the distance of proximity of objects performed the measurement through a high-frequency sound wave, which is reflected by the object to be detected, thus avoiding collision between the robot and the pipe wall. The performance of the coupling liquid reservoir was extensively tested after corrections and improvements, guaranteeing expressive and unprecedented results. The End-Effector technology was 100% innovative, from its conception, design, improvements, manufacturing and implementation, validated in a real laboratory environment. The results of the digital twins revealed the importance and support they offer in the development of scenarios for the study of robotic applications. It should be noted that they were not used for real-time monitoring of the problem. The aerial trajectory positions for the robot and their respective corrections and adjustments were defined. The complete version of the digital twin was validated by comparing the virtual scenario with the real scenario. The robot’s TCP was accurate and stable during the recording of points in a virtual environment. The first point was successfully recorded following the sequence of defined operations and without any type of human intervention. The first complete thickness measurement operation was created in a customized virtual environment and as a result the OLP (offline program) code for the real industrial robot was generated. The entire laboratory layout was calibrated with a laser system to avoid variation of the piping on the bench in relation to the floor and the base of the robot. Numerous tests were performed on the robotic system before the measurements were taken, which were extensively tested.

The counter-tests of the measurements at the first points of the pipeline were performed numerous times using a caliper to ensure a standard for comparison. The discussion of physical contact in the pipeline for automatic thickness measurement between the electronic measuring transducer and the pipeline took place after spraying the coupling liquid; a fundamental factor for the measurement to occur. When the robot’s End-Effector physically “touches” the pipeline, the sensor detects its presence and it enters “Hold” (a temporary stop). After this, the manipulator still exerts a small axial force to completely touch the face of the measuring transducer and ensure the quality of the procedure. Finally, the digital LCD display shows the measurement data and automatically records the value in its internal memory. Regarding the MTK 1301 Prime meter, the greatest difficulty was to equate the following variables: pre-established ultrasound speeds, calibration function with 3mm standard attached to the meter, sound speed calibration with 1 or 2 points, simple measurement or with sweep, individual measurement or with average calculation, measurement with audible alarm of minimum/maximum tolerance, measurement with differential calculation with percentage and improved measurement for pipe walls. The robotic manipulator operated at a safety speed of 10% (low inertia) in relation to the final nominal speed because the base of the robot was not “anchored” to the floor. The complete cycle time for spraying the glycerin and measuring each individual point took approximately 30 seconds.

6. Final Considerations

In this paper, we present the development of an advanced industrial robotic system for automatic inspection of tube wall thickness in the turbine building of nuclear power plants. A prototype of the system was built in the laboratory to study different situations and geometric configurations for measuring the external tube wall thickness. The digital twin of this prototype was developed using Process Simulate software version 16.1.2., including a 6-degree-of-freedom industrial robot, a metal platform, and nuclear tube sections. Digital validation was performed for various configurations of measuring the external tube wall thickness through virtual commissioning. The results of the virtual commissioning for a vertical pipe section were presented.

The virtual commissioning allowed to verify that any part of the external surface of the tube could be accessed by means of movements of the robotic arm along the sides of the tube. It was demonstrated that it is possible to measure the external tube thickness anywhere on the external surface of the nuclear tube.

The improvements in the End-Effector design were significant and the results in the design were unprecedented with numerous innovations, among them: automatic application of the coupling liquid.

The technology was digitally validated in the laboratory as shown in figures 5, 6, 7. It is currently in the final phase of experimental validation and will be presented to the plant directors. In the future, if it is of interest, it may be applied within the plant itself.

Conflict of Interest

The authors declare no conflict of interest.

Acknowledgment

The authors are grateful for the financial support of Eletrobras Termonuclear – Eletronuclear, Amazônia Azul Tecnologias de Defesa, Fundação Parque de Alta Tecnologia da Região de Iperó, and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – CAPES.

1. Introduction

Complex industrial facilities such as nuclear power plants require pipe wall thickness inspection for safe and reliable operation. These pipes, submitted to high pressure and temperature, connect the steam generators, turbine, condenser, and may undergo thickness reduction due to corrosion and erosion [1]-[3]. The inspection environment is hot and humid (50oC and 100 % relative humidity). The field space has complicated geometry and access to inspection locations, the pipes have diameters varying from 50 cm to 65 cm, and are positioned in horizontal, vertical, or inclined directions. During plant panned shutdown, the inspections may include tens of thousands measurement points of wall thickness [4], [5].

Traditional inspection systems are usually rigid and require intense human action to circumvent field unforeseen scenarios to make wall thickness measurement. Given the amount of work involved during inspections, it is desirable to automate these activities, and foresee access difficulties and variability of inspection conditions and pipes geometric configurations. To increase the efficiency to handle complex activities in changing scenarios, several authors propose the use of robotic automation systems with and without user assistive actions [6]-[8], and the use of digital twins and other industry 4.0 approaches to streamline their design and commissioning phases [9].

This work presents part of the development of a robotic system for measuring the wall thickness of the secondary

system pipes of the Angra 1 nuclear power plant, more specifically the development of its digital twin. This method allows dividing the development process into two stages, the first being development via simulation (virtual project) and the second stage in which the physical project is built from the virtual project data, including the robot programming that is exported from the virtual project to the field robot [10].

Digital twins are very realistic virtual models of a process and its interaction with the actual world environment [11]. They include the equipment and all the steps to carry out a certain production process [12]. Using the benefits of the digital twin and virtual commissioning tools, it is possible to increase communication and coordination between the parts of the process, allowing for smarter decision-making [12]. This technology makes it possible to quickly and flexibly develop different situations aimed at automating and integrating operator agents and robes to perform complex tasks [13]. It allows integrating sensory data from physical assets and simulating a variety of robotic conditions in which an agent can interact. As a result, the agent can learn an adaptive task allocation strategy that increases project performance. In [13], the authors tested this method for the robot-automated construction problem. Results indicated that model task allocation reduced build time by 36% in three dynamic test environments when compared to the conventional method.

The biggest benefit of virtual commissioning is the savings. It is possible to test an investment in advance, which could be hundreds of thousands or even millions of dollars in equipment, since a single robot could cost you around $50 to $70,000. [14]. So, five robots, equipment, clamp systems, accessories, different products, and all that together in one manufacturing cell is a significant investment. Companies do not intend to develop projects without knowing if it can satisfactorily perform at the expected levels and results. Process reduction Standard operating. Possibility of carry out part of this process in a more convenient environment (no necessarily on-site) combined with the opportunity to use the emulation model for training workers. Parallel development and optimization of mechanical parts, especially mechanisms mechatronics. [15]. Programming and debugging simultaneously from the control software. The Companies aim to implement sustainable manufacturing of robotic cells, in order to improve profitability, reducing resource consumption, global expenses, as well as satisfying the regulatory input of ecological impacts. In addition, the widespread adoption of industrial robots, necessary to satisfy the ever-increasing requirements in terms of manufacturing quality, customization and flexibility, further increased the need to improve the energy efficiency of robotic cells. [16].

This article is organized as follows: section 2 presents a State of Art, section 3 presents a brief description of the robotic system for pipe wall thickness measurement and section 4 presents the method used in this research, data and details of the equipment used. In section 5 we present the results and discussions and in section 6, the final considerations.

2. State of Art

This paper seeks to present, through emerging projects, the concept of digital twins was named one of Gartner’s Top 10 Strategic Technologies Trends for 2022 [17]. Thomas Kaiser, SAP Senior Vice President, IoT, put it this way: “Digital twins are becoming a business imperative, covering the entire lifecycle of an asset or process and forming the basis for connected products and services. Companies that fail to respond will be left behind.” It is estimated that within three to five years, billions of things will be represented by digital twins [18]. Using physical data about how a thing’s components operate and respond to the environment, as well as data provided by sensors in the physical world, a digital twin can be used to analyze and simulate real-world conditions, respond to changes, improve operations, and add value. Industry 4.0 (i4.0), which has been known as the “Fourth Industrial Revolution”, emerges with the aim of meeting this new global demand with customized products and services [19]. One of the concepts that will be widely used in i4.0 is the Digital Twin, which from a production perspective, incorporates the virtual context into the real context of a production system. In [20], Digital Twins are very realistic virtual models of the current state of the process and its own behavior in interaction with the real-world environment, including the equipment and all the steps to carry out a given production process [21], [22]. Using the benefits of the digital twin (DT) and virtual commissioning (VC) tools, it is possible to increase the advantage of communication and coordination between manufacturing areas, allowing for smarter decision-making. This allows automated systems and robotic cells to start operating (running) much faster and with fewer errors [23].

According to [24], the growing use of Virtual Commissioning during the development process of automated factories, combined with the growing demand for better quality control, leads to the need for improved virtual plants that systematize the configuration procedures required to perform their processes. Common plant simulation techniques based on the concept of virtual commissioning of robotic cells go beyond the need to validate control algorithms. In other words, new approaches need to be developed to meet the demand for reconfiguring their operational resources in a systematic way, compatible with the flexibility that these autonomous resources currently have. The need for new solutions in Robotics Engineering® for the design of complex projects involving physical systems and the virtual part associated with them has never been so present. Virtual commissioning technology can be considered as one of the established trends in automotive assembly. Among other benefits, it promotes more efficient treatment of the complexity associated with assembly systems, capable of causing a reduction in the acceleration time of the system itself and a reduction in the development time of the product capable of meeting market competitiveness.

According to [25], the digital twin synthesizes sensory data from physical assets and is used to simulate a variety of robotic construction site conditions in which an agent may interact. As a result, the agent can learn an adaptive task allocation strategy that increases project performance. They tested this method with a case project in which a virtual robotic construction project (i.e., interlocking concrete bricks are delivered and assembled by robots) was digitally twinned for training. The results indicated that the model task allocation reduced construction time by 36% in three dynamic test environments when compared to an imperative model rule-based method.

Along with the trends of mass customization, flexible robotic applications are becoming increasingly popular. Although conventional robotic automation of workpiece handling seems to have been solved, advanced tasks still require a lot of effort to achieve. In most cases, on-site robot programming methods, which are intuitive and easy to use, are not applicable in flexible scenarios. On the other hand, the application of offline programming methods requires careful modeling and planning. Consequently, [26] proposes a generalized approach to the development methodology for flexible pick-and-place robotic work cells in order to provide guidance and thus facilitate the development process. The methodology is based on the Digital Twin (DT) concept, which allows iterative refinement of the work cell in both the digital and physical space. The goal is to streamline the overall commissioning (or reconfiguration) process and reduce the amount of work in the physical work cell. This can be achieved by digitizing and automating the development and maintaining sufficient proximity. With this, the operation of the digital model can be performed accurately in the physical work cell. The methodology is presented through a semi-structured pick-and-place task, performed in an experimental robotic work cell in conjunction with a reconfiguration scenario [27]-[28].

3. Brief Description on of the Advanced Robotics System

The Robotic System for pipe wall Thickness Measurement (RSTM) aims to meet the licensing needs of the Angra 1 Nuclear Power Plant for long-term operation in fast and efficient manner [29]. This RSTM has 3 units, the first, named Unit of Remotely Operated Vehicle (UROV), being a vehicle that can be operated remotely to allow displacement of the whole RSTM to the pipe area under inspection. The second unit, named Unit of Measuring Robotic Cell (UMRC), is a robotic work cell indexed on the UROV and equipped with a robotic arm that performs the movements and inspection actions and an effector with sensors for spatial orientation and for measuring pipe wall thickness through the ultrasound technique. The third unit contains all other RSTM systems such as power supply cables, data transmission cables, real-time information, computer, and ancillary equipment. This unit is named Unit of Communication, Power supply and Ancillary services (UCPA) [29].

The RSTM must be able to approach the defined inspection location and measure the thickness of the pipe wall. Figure 1 shows the complexity and geometric variability of the piping system in the field (turbine building). The solution provided for the inspection problem is a hybrid, contemplating the assistance action of the user to approach the inspection region, and robotic automation to perform the final approach to the inspection locations on the pipe surface and wall thickness measurements. An example of actual inspection locations is the grid of yellow circles shown in Fig. 1. The robot end-effector has an ultrasound-based approximation sensor to provide spatial orientation and an ultrasound-based sensor for pipe wall thickness measurement [30].

Figure 1: Piping section showing the environment and situation of pipe inspection at Angra nuclear power plant 1. Circles show positions indicated by the engineering group for pipe thickness inspection.

The user operates the UROV to approach the RSTM to the measuring locations on the pipe external surface. The first grid location must be manually identified and recorded by the user, that is, with the help of the “teach pendant” he or she moves the industrial robot end-effector through the piping environment to the first measurement position marked on the pipe wall and register its coordinates. From there, the robot present in the UMRC, with its spatial orientation system, automatically scans all the measuring points on the grid and automatically performs the wall thickness measurements. After carrying out the measurement, the result must be transmitted to the UCPA through the communication interface with the plant.

While conventional robotic automation for handling workpieces and performing specific tasks seems to have been resolved, more complex tasks in less controlled environments, such as in the field, require more flexible solutions. In most cases, robot programming methods in a controlled environment are not applicable in variable scenarios found in the real world [31].

4. Methods, Data and Equipment

The use of the Digital Twin concept in an iterative way, both in the digital space and in the physical space, to refine the work cell development process is the solution adopted in this work. The objective is to streamline the overall commissioning process with different configurations or reconfigurations according to the work situation [31]-[32].

Figure 2 presents the main steps of the approach based on the digital twin technique for the UMRC development. The software adopted to develop the digital twin is the Tecnomatix Process Simulate, version 16.1.2 and the robot used is the ABB IRB 1600-6/1.45 model.

Figure 2: Scheme of the method for developing robotic systems using the digital twin technique. All the capabilities of the robot are developed via programming (software) and virtual commissioning is carried out via simulation of the various tasks that the robot must perform until its validation.

Figure 3 shows the robotic cell prototype installed at the UFABC Robotics Laboratory to develop the UMRC that contains the intelligent part of the robotic measurement system. The robotic cell includes ABB IRB 1600-6/1.45 robot, the metal platform and two pipe sections taken from the Angra 1 nuclear power plant. The pipe section is assembled on the platform in different geometric configurations and situations emulating actual measurement conditions. These configurations are obtained from field situations like the one shown in Figure 3 or others from field situations as shown in Figure 1.

Figure 3: Piping Robotic cell in the Laboratory emulating the UMRC. One sees the ABB IRB 1600-6/1.45 robot, the metallic platform and two pipe sections taken from the Angra 1 power plant

Automatic measurement was performed numerous times using various measurement techniques to ensure repeatability, accuracy and robustness of the measured data. The ultrasonic thickness gauge from the manufacturer METROTOKYO used was the MTK-1301 PRIME model. The electronic transducer was the standard 5MHz/Ø10mm model. The longitudinal wave speed for the “glycerin” material was 1920 m/s and for the 330-steel material it was 5600 m/s, respectively, the speed of sound. Figure 4 shows the specification of the system’s measuring sensors.

Figure 4: Meters used: A-) Model Prime 1300. B-) Model Prime 1301. C-) Transducer Model.

The older model did not allow data extraction, as it did not have a USB connection. Therefore, the MTK-1301 PRIME meter model was used, with the following features:

- Manual or automatic shutdown after a period of non-use;

- Table of 9 pre-established ultrasound speeds;

- Calibration function with 3mm standard attached to the meter;

- Calibration of the speed of sound with 1 or 2 points;

- Simple or sweep measurement;

- Individual measurement or with average calculation;

- Measurement with audible alarm for minimum/maximum tolerance;

- Measurement with differential calculation with percentage;

- Measurement on a surface with high temperature (optional sensor);

- Improved measurement for pipe walls. measurement

Figure 5: Ideal amount of glycerin: A-) Approximately 50g of glycerin controlled by the time the regulating valve is activated. B-) Spraying at 40 different points in the piping. C-) Visual inspection of the “micro-mesh” to prevent drying.

Figure 5 shows evidence of the unprecedented procedure developed in the laboratory for applying the coupling liquid. It was observed through numerous tests that a small amount of coupling liquid (glycerin) interferes with the quality of the measurement, that is, there are chemical reactions between the electronic transducer nozzle, the type of pipe material and the amount of glycerin. The measurements remained stable with two sprays per point and the robotic manipulator program was adjusted for this function through the “pulse” command.

The Communication, Power Supply and Ancillary Services Unit (UCPA) fulfilled the scope of its title. For the communication part, the principles of Industry 4.0 were adopted, which seeks to integrate the “work field”, the engineering group and other sectors that Eletronuclear may require. After the thickness measurement was performed, the result was transmitted to the UCPA through a communication interface. These enabling technologies of Industry 4.0 follow data security and interface communication protocols based on APIs (Application Programming Interface) that allow applications to be customized according to Eletronuclear’s needs. The UCPA was created and developed based on a new, more modern thickness gauge model that allowed access and transfer of the measured data that was stored inside the gauge to an external computer. Figure 7 and Figure 7 shows both systems.

Figure 6: Different views and settings of automatic measurement.

Figure 7: UCPA Communication Interface.

- USNRC-NUREG–2191. “Generic Aging Lessons Learned for Subsequent License Renewal (GALL-SLR) Report”, Final Report Vol. 2. US Nuclear Regulatory Commission, 2017.

- IAEA-SRS 82. Ageing management for nuclear power plants: International generic ageing lessons learned (IGALL), Rev. 1. International Atomic Energy Agency, 2020.

- S. A. Cancemi; R. L. Frano; Preliminary study of the effects of ageing on the long-term performance of NPP pipe. Progress in Nuclear Energy, 131, 103573, 2021.

- Q. Zhang; Y. Li; E. Lim; J. Sun. Real Time Object Detection in Digital Twin with Point-Cloud Perception for a Robotic Manufacturing Station. Proceedings of the 27th International Conference on Automation & Computing, University of the West of England, Bristol, UK, 1-3 September 2022.

- H. Zhou; S. Zhang; J. Zhang; C. Zhang; S. Wang; Y. Zhai; W. Li. Design, development, and field evaluation of a rubber tapping robot. Journal of Field Robotics, 39, 28–54, 2021.

- Tugal, H.; Cetin, K.; Petillot, Y.; Dunnigan, M.; Erden, M. S. Contact-based object inspection with mobile manipulators at near- optimal base locations. Robotics and Autonomous Systems, 161, 104345, 2023.

- J. Barbosa, P. Leitão, E. Adam and D. Trentesaux, “Dynamic self- organization in holonic multi-agent manufacturing systems: The ADACOR evolution,” Computers in industry, v. 66, p. 99-111, 2015.

- J. Barata, L. Camarinha-Matos and M. Onori, “A multi-agent-based control approach for evolvable assembly systems,” INDIN’05. 2005 3rd IEEE International Conference on Industrial Informatics, pp. 478-483, August 2005.

- E. Trunzer, A. Calà, P. Leitão, M. Gepp, J. Kinghorst, A. Lüder et. al., “System architectures for industrie 4.0 applications,” Production Engineering, v. 13, n. 3, p. 247-257, 2019.

- Boschert, S.; Rosen, R. Digital Twin—The Simulation Aspect. In: Hehenberger, P.; Bradley, D. (Editors), Mechatronic Futures – Challenges and Solutions for Mechatronic Systems and their Designers. pag. 59-74, Spring, 2016.

- Bratchikov,S.; Abdullin, A.; Demidova, G. L.; Lukichev, D. V. Development of Digital Twin for Robotic Arm. 2021 IEEE 19th International Power Electronics and Motion Control Conference (PEMC) DOI: 10.1109/PEMC48073.2021.9432535, 2021.

- Nekoo, S. R.; Acosta, J. A.; Heredia, G.; Ollero, A. A benchmark mechatronics platform to assess the inspection around pipes with variable pitch quadrotor for industrial sites. Mechatronics 79, 102641, 2021.

- Lee, D. et al. Digital twin-driven deep reinforcement learning for adaptive task allocation in robotic construction. Advanced Engineering Informatics, v. 53, 1 ago. 2022.

- Gartner Top 10 Strategic Technology Trends For 2018. Disponível em <https://www.gartner.com/smarterwithgartner/gartner-top-10-strategic-technology-trends-for-2018>. Acesso em: 20 fev . 2023.

- What Is Digital Twin Technology – And Why Is It So Important? Disponívelem:..<https://www.forbes.com/sites/bernardmarr/2017/03/06/what-is-digital-twin-technology-and-why-is-it-so-important/?sh=1365c81c2e2a>. Acesso em: 20 fev. 2023.

- Tugal, H.; Cetin, K.; Petillot, Y.; Dunnigan, M.; Erden, M. S. Contact-based object inspection with mobile manipulators at near-optimal base locations. Robotics and Autonomous Systems, 161, 104345, 2023.

- Bratchikov,S.; Abdullin, A.; Demidova, G. L.; Lukichev, D. V. Development of Digital Twin for Robotic Arm. 2021 IEEE 19th International Power Electronics and Motion Control Conference (PEMC) DOI: 10.1109/PEMC48073.2021.9432535, 2021.

- Nekoo, S. R.; Acosta, J. A.; Heredia, G.; Ollero, A. A benchmark mechatronics platform to assess the inspection around pipes with variable pitch quadrotor for industrial sites. Mechatronics 79, 102641, 2021.

- Qiu, B. et al. A Feasible Method for Evaluating Energy Consumption of Industrial Robots. Proceedings of the 16th IEEE Conference on Industrial Electronics and Applications, ICIEA 2021. Anais…Institute of Electrical and Electronics Engineers Inc., 1 ago. 2021a.

- Lee, D. et al. Digital twin-driven deep reinforcement learning for adaptive task allocation in robotic construction. Advanced Engineering Informatics, v. 53, 1 ago. 2022.

- Partiksha; K., A. Robotic Tele-operation Performance Analysis via Digital Twin Simulations. 2022 14th International Conference on COMmunication Systems and Networks, COMSNETS 2022. Anais…Institute of Electrical and Electronics Engineers Inc., 2022.

- Fan, S. et al. A new approach to enhance the stiffness of heavy-load parallel robots by means of the component selection. Robotics and Computer-Integrated Manufacturing, v. 61, 1 fev. 2020.

- Huynh, H. N. et al. Modelling the dynamics of industrial robots for milling operations. Robotics and Computer-Integrated Manufacturing, v. 61, 1 fev. 2020.

- Vitalli, R. Método de abordagem e estrutura geral do projeto de pesquisa desenvolvimento da RSTM. Documento Número: UFABC- ROBOT-001-Rev00, 2023.

- Partiksha; K., A. Robotic Tele-operation Performance Analysis via Digital Twin Simulations. 2022 14th International Conference on Communication Systems and Networks, COMSNETS 2022. Anais…Institute of Electrical and Electronics Engineers Inc., 2022.

- Fan, S. et al. A new approach to enhance the stiffness of heavy-load parallel robots by means of the component selection. Robotics and Computer-Integrated Manufacturing, v. 61, 1 fev. 2020.

- Huynh, H. N. et al. Modelling the dynamics of industrial robots for milling operations. Robotics and Computer-Integrated Manufacturing,v. 61, 1 fev. 2020.

- SIEMENS PLM, Process Simulate. Germany. Siemens Product Lifecycle Management Software. 2018. Document ID: MT45215. Version: 15.1.2.

- ABB, Product manual IRB 1600/1660. Sweden. ABB Robotics. 06/01/2022. Document ID: 3HAC026660-001. Revision: AH.

- Wildgrube F, Perzylo A, Rickert M, et al. Semantic mates: Intuitive geometric constraints for efficient assembly specifications. 2023 IEEE/ RSJ International Conference on Intelligent Robots and Systems (IROS); 2023.

- Rauen H. Industrie 4.0 in practice – Solutions for industrial applications. Frankfurt: VDMA Industrie 4.0 Forum; 2023.

- Karaman S, Frazzoli E. Sampling-based algorithms for optimal motion planning. The International Journal of Robotics Research.2024;30(7):846–894.

No related articles were found.